The aerospace industry has special requirements for corrosion and heat resistance. This is why light metals and their alloys, with or without functional coatings, are used. Functional coatings include the so-called MCrAlY coatings. MCrAlY coatings, which are normally produced by physical deposition from the vapor phase using electron beam or thermal spraying, are often used to protect superalloys against high-temperature oxidation and corrosion. In addition to Y, other elements such as Ta, Hf and Si have also proved useful. MCrAlY coatings (where M = Co, Ni or Co/Ni) are widely applied to first and second stage turbine blades and nozzle guide vanes where they can be used as corrosion resistant top coats or as adhesion promoters for thermal barrier coatings.

Engineers at Tennessee Technological University and ORNL in the USA have produced NiCoCrAlX coatings (where X = Y, Ta, Hf and/or Si) by an electrodeposition process in a sulphate-based Ni-Co coating solution. It was observed that the quality of the electrodeposited coatings depends on many interrelated parameters, including the type of electrolyte, current density, pH, concentration of particles in the coating solution (particle loading), particle properties (composition, surface charge, shape, size), hydrodynamics in the electroplating cell, position of the cathode (sample) and, if applicable, post-deposition heat treatment. Compared to uncoated René 80 substrates, the electrodeposited NiCoCrAlX coatings showed higher performance in oxidation tests with a cycle frequency of 1 hour at 1000 °C and 1100 °C.

A further improvement in oxidation resistance was observed for the coatings with Hf and Si additives, but not with Ta additives. The content of S, Y and O in the electrodeposited NiCoCrAlY coating was measured using high-resolution glow discharge mass spectrometry (GDS) and compared with the content in thermally sprayed coatings. The cyclic oxidation behavior of NiCoCrAlX coatings (with X = Y, Ta, Hf and/or Si) produced by electrodeposition was investigated at 1000 °C and 1100 °C. Compared to the uncoated Ni-based superalloy René 80, which exhibited rapid oxidation and severe scale delamination, the electrodeposited NiCoCrAlY coatings showed superior resistance to cyclic oxidation at both temperatures.

Materials and Coatings 2022, 73, 5, pp. 747-757; https://doi.org/10.1002/maco.202112843

Electroforming of sugar sieves

Netherlands-based micro-precision parts manufacturer Veco BV, a member of the Muon Group, has acquired a total area of over 20,000 square meters in Chakan near Pune to set up its manufacturing facility. Veco BV is the world's leading manufacturer of micro-nozzle plates and sugar screens with electroforming as a key technology. The company holds more than 70% of the market share in this segment. Marketing and technical support for customers in Asia is handled by Atul Sugar Screens in Pune. After Brazil, India is the largest producer of sugar.

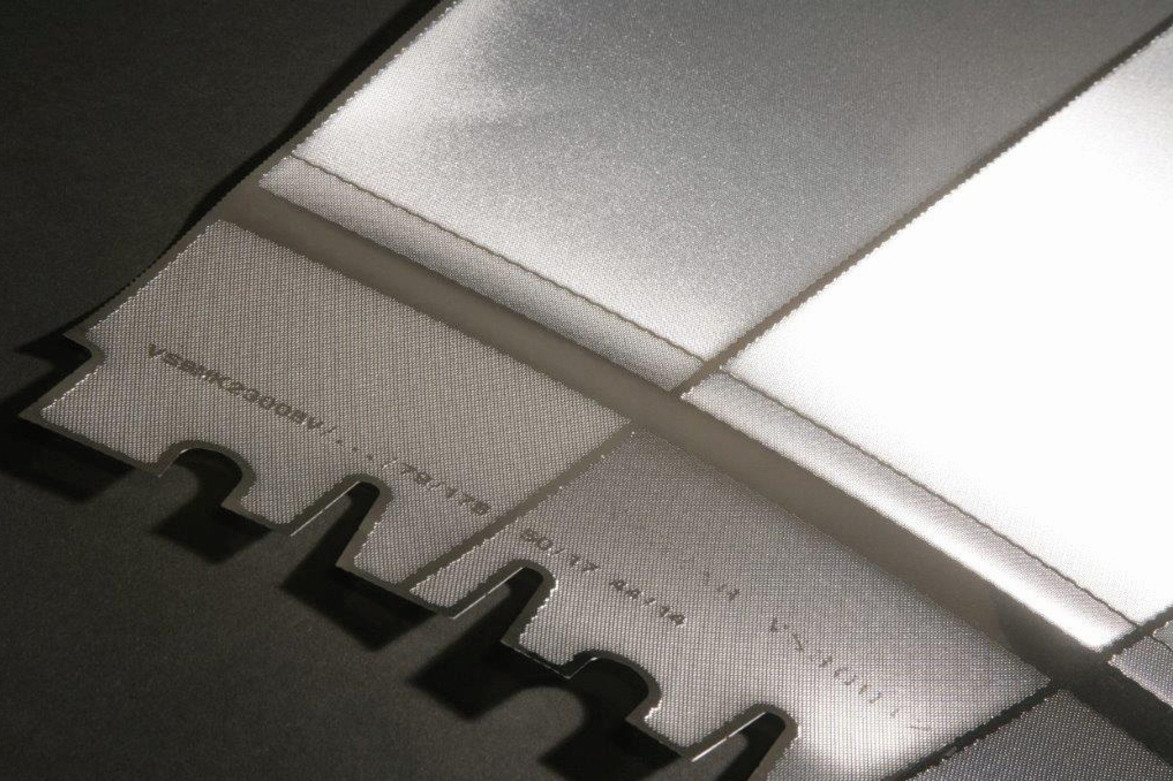

Electroforming of sugar screens

Electroforming of sugar screens

Veco is a recognized leader in electroplating processes with a wide range of functional coatings including gold, silver, chrome, phosphorous nickel, black nickel/chrome, ruthenium and platinum. In addition to electroplating, Veco also offers other in-house finishing services such as passivation, insulation and laser welding. The Muon Group also consists of centers of excellence in electroforming, chemical etching and laser material processing.

Safran expands in India

Safran operates an aircraft engine wiring plant in India and plans to expand furtherTheParis-based Safran Group, which employs around 77,000 people in 27 countries, is expanding its activities in Hyderabad and Bengaluru in India. The French group will invest 200 million US dollars (approx. 195 million euros) over seven years until 2025. The 150 million dollar facility for the maintenance, repair and overhaul of aircraft engines that Safran plans to build in Hyderabad will be the French aerospace group's largest worldwide, will employ up to 1,000 people and is expected to go into operation in 2025. In ten years' time, the plant is expected to have a capacity to restore the performance of 300 engines per year and employ up to 1,000 people.

Safran operates an aircraft engine wiring plant in India and plans to expand furtherTheParis-based Safran Group, which employs around 77,000 people in 27 countries, is expanding its activities in Hyderabad and Bengaluru in India. The French group will invest 200 million US dollars (approx. 195 million euros) over seven years until 2025. The 150 million dollar facility for the maintenance, repair and overhaul of aircraft engines that Safran plans to build in Hyderabad will be the French aerospace group's largest worldwide, will employ up to 1,000 people and is expected to go into operation in 2025. In ten years' time, the plant is expected to have a capacity to restore the performance of 300 engines per year and employ up to 1,000 people.

India is a major customer for the Rafale fighter jet. The MRO (Maintenance, Repair & Operations) facility is planned to provide space for the maintenance of the M88 - the engine for the Rafale fighter jets. The MRO facility is also intended for CFM LEAP engines. Safran Aircraft Engines' 15,000 square meter facility will produce rotating parts for the LEAP engine. The Safran Electrical & Power plant, where the cabling for the LEAP engines and Rafale fighter aircraft is manufactured, was opened in November 2018 and is already planning to expand.

Safran workers in India. The company plans to invest 150 million dollars in a new plant in Hyderabad

Safran workers in India. The company plans to invest 150 million dollars in a new plant in Hyderabad

Wacker Chemie with new production site

Wacker Chemie and its Indian joint venture Wacker Metroark Chemicals have been operating a production site for silicones in Amtala near Kolkata since 1999. A new production site for silicones was recently opened in Panagarh, about 160 northwest of Kolkata. It produces silicone rubber and ready-to-use silicone compounds for the electromobility, medical technology and electrical transmission and distribution sectors. With an area of 165,000 square meters, the new plant is three times larger than the one in Amtala, where silicone oils and emulsions for the cosmetics and personal care industry continue to be produced. The site is part of Wacker's new growth strategy. In order to meet the increasing demand for silicones in India and consolidate its position as a leading silicone manufacturer, Wacker has announced an investment in the mid double-digit million euro range in Panagarh over the next few years.

Overview article: Anodizing - The pore makes the difference

With 150 references: https://onlinelibrary.wiley.com/doi/epdf/10.1002/maco.202213324