Not all digital is the same. A digital solution only helps if it is tailored to a company's work processes.

Every surface technology company has its own processes and structures - but the entire industry is facing similar challenges. Customers are demanding ever tighter deadlines and the batch sizes of individual orders are shrinking. At the same time, quality assurance requirements are increasing. This often results in similar questions, such as: How can we provide our customers with more straightforward information about the status of their goods? Where can we save time? This is made possible by digitalization.

Surface technology is a multi-faceted industry with a wide variety of companies. From five-man companies to corporate groups with several locations and hundreds of employees, a broad spectrum is represented. It is therefore understandable that different approaches are taken to similar issues.

Order processing in one system

Valuable time elapses before an order is created in the incoming goods department, as the order data often only arrives with the goods at the yard. Special features are noted on paper and are sent with the goods to production - where, in the best case scenario, what has been written down is not lost and ends up in a pile to be typed up again. The delivery bills are written elsewhere in the office and then printed. This example illustrates the problem of so-called "island solutions". This refers to solutions and programs that are used in isolation - like an island - for individual tasks. Shipping information from island to island involves a great deal of effort and time delay.

The introduction of centralized data management and processing is therefore an important cornerstone for digitalization. ERP (Enterprise Resource Planning) systems are often used for this purpose. In short, the system controls, plans and optimizes company processes from goods receipt to production and invoicing. This simplifies the exchange of data between different departments; once information has been recorded, the ERP stores it. For example, recurring articles do not have to be entered again, but can be retrieved from the database; the same applies to customers and customer groups. This master data can be used during order entry to simplify input. At the same time, changes at order level, such as one-off special features, do not have to be transferred to the master data.

As a central collection point for information, an ERP also makes it easier to search for specific information in the event of customer queries. Internal documents such as production papers/operating orders can be created in the same way as delivery bills and invoices. These digital documents can then also be sent directly by email - this is less complicated and saves on postage costs.

Better exchange between administration and production

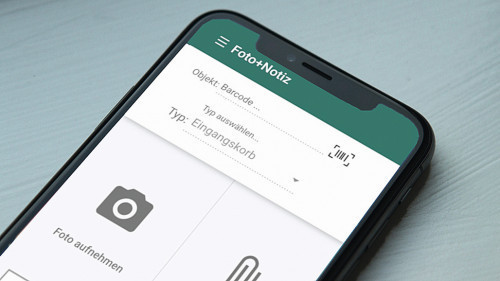

Photo and note app that can be used for documentation in the company (Photo: Softec)Terminals are often used to transfer data from production to the ERP system, or interim statuses are only reported back by telephone following queries. If current production data is to be available, for example to answer customer queries directly on the phone, data must be recorded in the respective production step. Solutions for mobile devices that we are familiar with from our private lives are ideal for this: Apps.

Photo and note app that can be used for documentation in the company (Photo: Softec)Terminals are often used to transfer data from production to the ERP system, or interim statuses are only reported back by telephone following queries. If current production data is to be available, for example to answer customer queries directly on the phone, data must be recorded in the respective production step. Solutions for mobile devices that we are familiar with from our private lives are ideal for this: Apps.

Special industrial apps share many of the characteristics of these apps. They are easy to use, fulfill specific functions and are always available via the smartphone. The advantages are obvious. Data can be recorded directly on site instead of having to walk to terminals or even from production to the office. This allows production data acquisition (PDA) to take place at every work step. The stored order data is loaded via barcode scans of individual work steps on the work order. Employees only have to select a message type, add quantities and any notes and send the message. This information automatically ends up in the ERP system and updates the corresponding order.

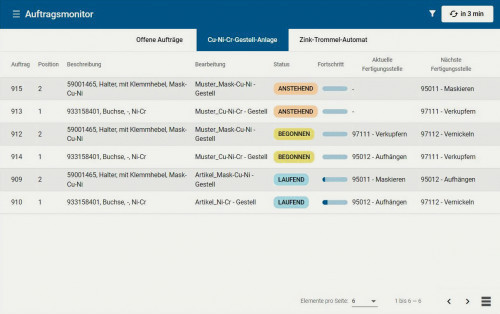

Apps can not only be used to transmit information from production, but also to display this updated information. For example, in an "order monitor", which is used not only on mobile devices but also on large screens. This means that employees in production are always informed about planning changes and the current order situation.

One example of an app that can be used not only in production is photo documentation. This is because documentation is often much easier and clearer with photos. For example, for new article images, load securing or even for faulty parts that are complained about in the incoming goods department. Here too, the direct connection to the ERP system ensures that the photos are stored correctly. An order or article is selected via the barcode assignment or search function, the photo is taken, notes are added and everything is transferred to the ERP system. The otherwise complicated process of transferring photos to the computer and then filing them correctly is broken down into a simple process that is similar to sending photos via a messenger app.

Automated feedback

Automated processes in which data is transferred to the ERP system are a variant or supplement to mobile feedback. This has several advantages: the transfer takes place in real time and employees do not have to integrate any additional steps into the workflow.

One area of application is the tracking of goods using RFID technology. Instead of having to enquire about the current status of goods in production when customers make inquiries, RFID can provide a movement profile that seamlessly monitors the location of goods. This enables employees to answer inquiries directly on the phone and provide more precise estimates of delivery dates.

RFID stands for Radio Frequency IDentification and enables the location of objects to be tracked using transponders, antennas and readers. The object to be tracked is fitted with a transponder. Two antennas form so-called "gates" at important passages. The antennas transmit the data from transponders that pass through the gate to a reader.

Large quantities of metal, which are present in every electroplating plant, pose a challenge. This is because the metal interferes with the reliable radio transmission of the transponders. To ensure radio transmission nevertheless, a plastic document pocket is fitted with a transponder. This bag can be attached to the outside of containers such as pallet cages and ensures the necessary distance. Individual transponders can also be tracked fully automatically on forklift trucks with several containers. A movement profile for the transponder and thus for the container or order can be created from the individual measurements of locations and times.

Another type of feedback is the system link. The systems exchange data directly via a software interface to the ERP and transmit values from the countless sensors installed in modern systems. Such interfaces can also be used to send planning data to systems, for example, in order to carry out decentralized optimization of scheduled orders.

Networking makes it possible to react more quickly to deviations in the process and to collect and process available data.

Overview of production data ensures product quality

It is also clear that processed plant data should ideally be available in production. This is because the faster deviations are detected on site, the faster the reaction time. This predictive maintenance and servicing of systems supports consistently high product quality.

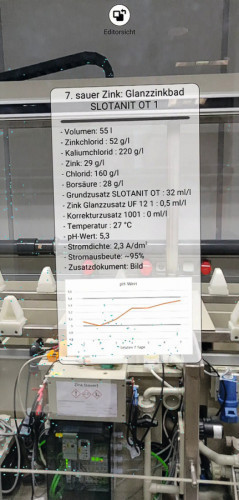

A practical way to display data wherever it is relevant is to use augmented reality. Using a smartphone app, virtual data panels are superimposed on the camera image at suitable points so that information on a specific system can also be seen directly on this system. Similar to head-up displays in cars, the aim is to bring the information into the viewer's field of vision. The app is continuously fed with real-time data from the ERP system via corresponding interfaces so that irregularities are noticed.

Order monitor for displaying planned orders in production (Screenshot: Softec)To set up the app, the production environment needs to be recorded once. Data panels can be easily placed in the room using the app's own editor mode; the app uses anchor points to remember where individual data panels should appear in relation to the room; objects such as systems can be recorded as simple geometric shapes.

Order monitor for displaying planned orders in production (Screenshot: Softec)To set up the app, the production environment needs to be recorded once. Data panels can be easily placed in the room using the app's own editor mode; the app uses anchor points to remember where individual data panels should appear in relation to the room; objects such as systems can be recorded as simple geometric shapes.

The example of augmented reality also shows how flexible new digitalization concepts can be. The functionality is not only used in maintenance, but can also be transferred to other areas. For example, indoor navigation in the warehouse or use for training purposes to teach new employees is conceivable.

Finding the right way

Surface finishers have many options for dealing with the increasing demands of customers; the digital solutions presented here cover just some of them. It is therefore difficult to name a blanket solution. Instead, the goal for surface finishers should be to find solutions that are individually tailored to their company and their specific requirements. Discussions with employees can help to identify time-consuming or unnecessarily complicated processes and work out the greatest potential for optimization on this basis. The result can be simple, digital order processing or fully networked production with system links. Both are digitalization.

One advantage is that individual solution approaches are never isolated solutions. Different solution approaches can therefore be combined, which in turn creates added value. The central management of order data described above is the basis for further applications based on it, such as the order monitor for displaying planned orders in production.

Little by little, each company is creating its very own path to digitalization.