In the past, economic growth meant increased consumption of energy and raw materials, but in the face of increasingly scarce resources and exploding energy prices, new solutions are needed. The war in Ukraine, the Russian embargo with missing gas supplies and disrupted supply chains, climate change, REACh, international competition, a shortage of skilled workers - it has never been more important to manage resources and reduce costs and emissions. The key to success is digitalization, which enables timely process correction through data collection and evaluation.

Initial situation and goals of digitalization in surface treatment SMEs

Although the coronavirus pandemic has accelerated the pace of digital transformation in large parts of society, there is still a lot to do in small and medium-sized companies in the production sector. In surface technology, digital media are often used for information and communication in administration (accounting, purchasing, customer contact or personnel management); ERP systems help to monitor the flow of goods from receipt to delivery.

Intelligently networking all of the complex production processes is one of the major challenges. The analogue material and goods flows need to be digitally mapped, made transparent and tracked so that information can be obtained for optimization decisions without losing sight of the actors involved: the people.

If this networking is successful and the right conclusions are drawn from the data obtained, the benefits are immense:

- Increasing product quality to a permanently high level

- Efficient use of required resources such as raw materials, materials, equipment and personnel

- Increased economic efficiency

- Data generation for predictive maintenance

- Avoidance of cost-intensive downtimes

- Reduction of emissions in order to achieve climate targets.

Networking machines via interfaces and energy management

The cornerstone of digitalization is the consistent networking of machines and processes, including peripherals. The basic prerequisite for creating the necessary interfaces is knowledge of the processes and consumption. In addition to technical know-how, this requires an interdisciplinary exchange with all those involved: Plant planners and builders, users, chemists and technicians and IT staff. This requires cooperation and foresight, knowledge of effects and interactions, because the right information needs to be linked together, visualized and made available to the respective target group for further processing.

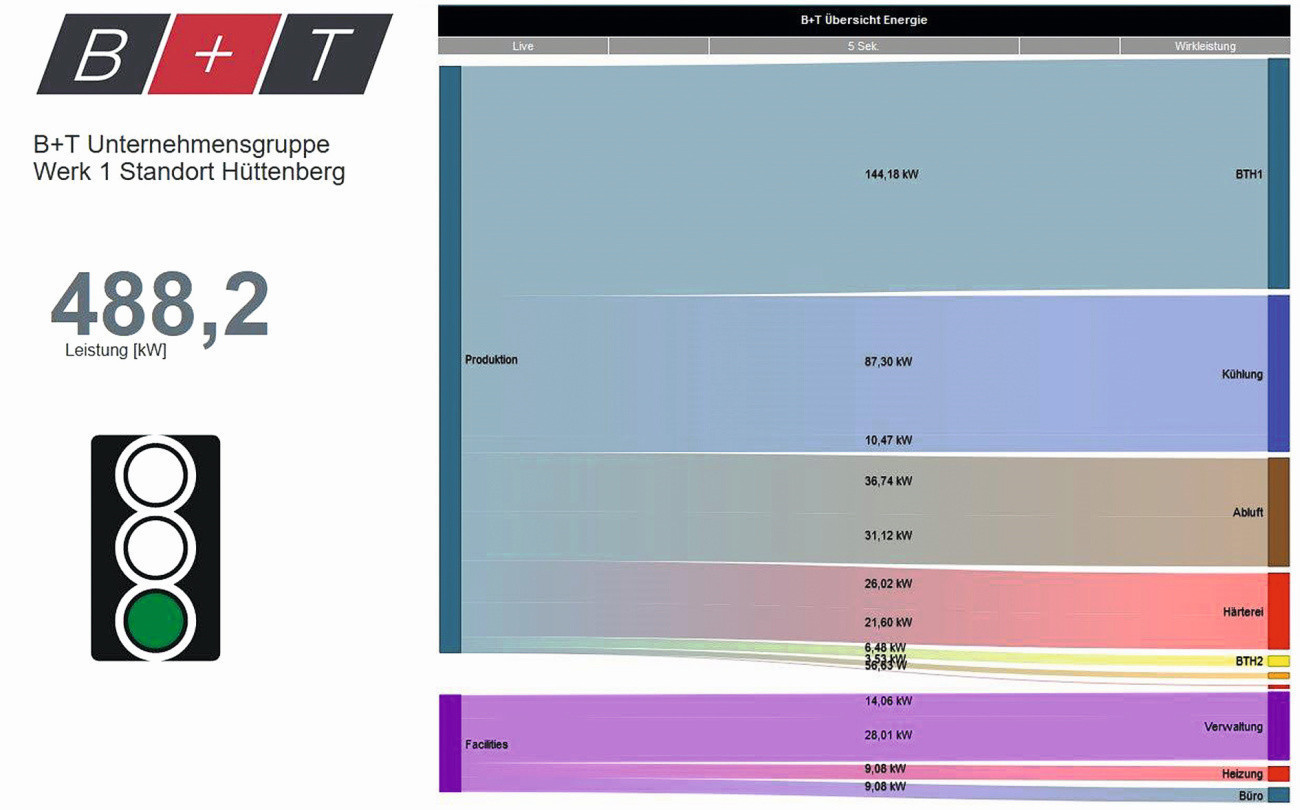

Fig. 1: The live energy consumption of the individual areas is visualized here as a Sankey diagram. It can be seen at a glance that consumption is in the "green zone"

Fig. 1: The live energy consumption of the individual areas is visualized here as a Sankey diagram. It can be seen at a glance that consumption is in the "green zone"

B+T Oberflächentechnik GmbH from Hüttenberg began digitizing individual processes years ago, but since January 2022 the focus has shifted to the entire production chain. B+T is part of the BeStPeri research project (demand-oriented control of peripheral systems in production), in which the resource efficiency of the entire production process is considered for demand-oriented supply of operating resources and control of peripheral systems. Sensors installed at the relevant points record the inflow and outflow of raw materials and supplies at defined time intervals. As part of the research project, these are combined using machine learning and economically and ecologically valuable key figures are predicted on this basis. The trained models are then integrated into production as services for predictive maintenance.

Find out more at www.wzl.rwthaachen.de/cms/wzl/Das-WZL/Presse-und-Medien/Aktuelle-Meldungen/~svntn/Ressourceneffizienz-im-Kontext-der-Ener/

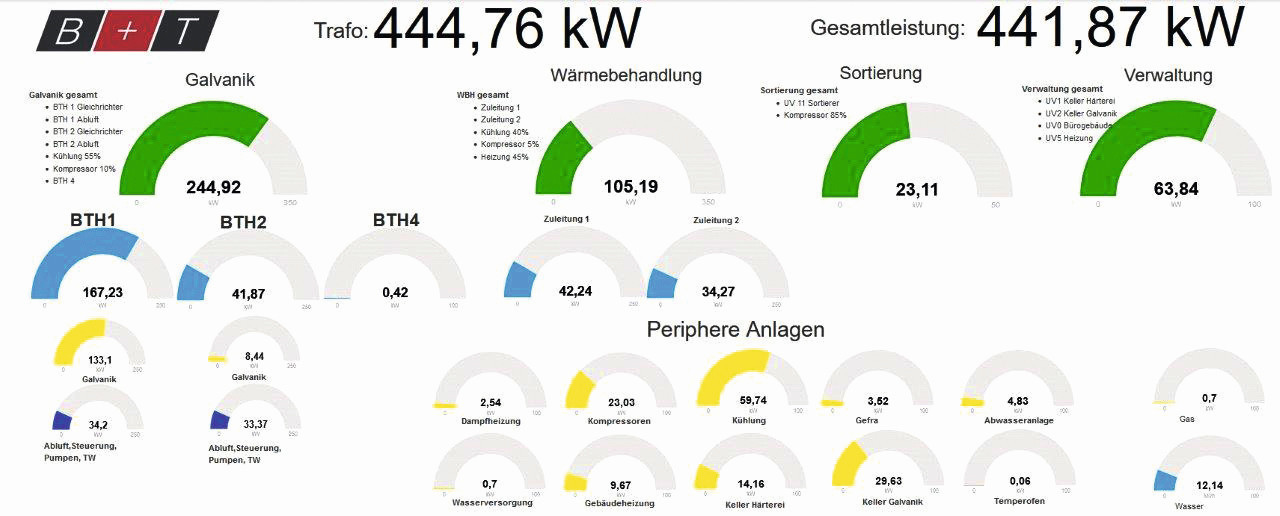

The data recorded by sensors on systems, peripherals etc. is fed into the software together with data from external meters or virtual measuring devices and processed for display. Here it is defined in which way which information is displayed, be it limit values for the fastest possible information acquisition and evaluation or comparisons over certain periods of time (Fig. 1 and 2).

Fig. 2: Each individual sensor provides data that can be viewed individually or clustered or cumulated thematically

Fig. 2: Each individual sensor provides data that can be viewed individually or clustered or cumulated thematically

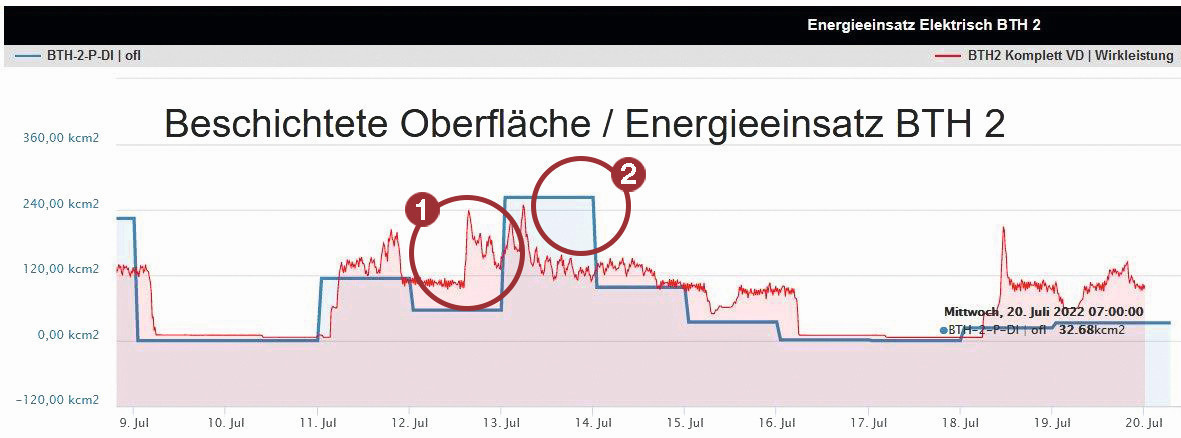

Using the example of the "coated surface" values, which are set in relation to the "energy input" in the defined time frame of system BTH 2, gaps are evident, the cause of which still needs to be clarified.

1) How is it possible to achieve more surface coating with less energy? And 2) Why is the energy consumption constantly high during this period, even though less surface was coated (Fig. 3 and 4)?

Fig. 3: The coated surface (red area) is set in relation to the energy input (blue line) in the period July 9-20

Fig. 3: The coated surface (red area) is set in relation to the energy input (blue line) in the period July 9-20

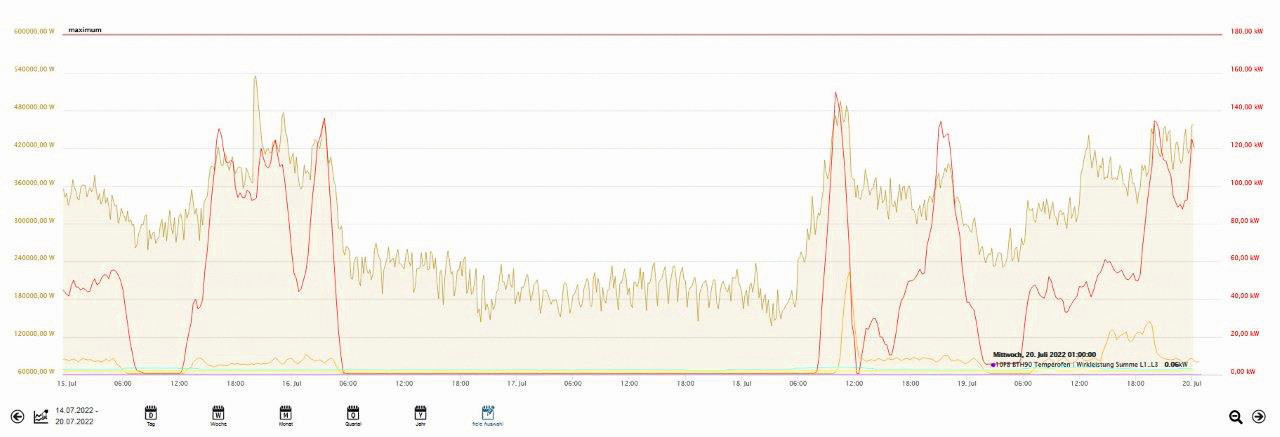

Fig. 4: The upper limit shown in Fig . 4 indicates that the electricity consumption at the local supplier is currently still within the booked power price and therefore no classification with higher costs is imminent

Fig. 4: The upper limit shown in Fig . 4 indicates that the electricity consumption at the local supplier is currently still within the booked power price and therefore no classification with higher costs is imminent

Digitalization of analytics at B+T

In addition to equipping the systems and baths with sensors for monitoring, regulation and control tasks, in-process analysis plays a central role in surface coating; for example with the RF-200 CF Pro, the X-ray analysis device from B+T K-Alpha, which can measure the metal content of the baths fully automatically and online every minute, while the analysis in the laboratory can provide results for bath correction after 1-2 hours and in the external laboratory only after 1-2 days. Apart from the time aspect, online analysis enables constant bath management within narrow control limits without the expertise of a laboratory technician in 3-shift operation.

The analytical at-line method "gravimetric titration with the alino from Gravitech" also offers enormous potential for saving resources. Compared to volumetric titration, the use of chemicals and the time required can be reduced by more than 50 %. Another advantage of the method is the simple menu navigation, which achieves good reliability and certainty of results even when the analyses are carried out by untrained staff.

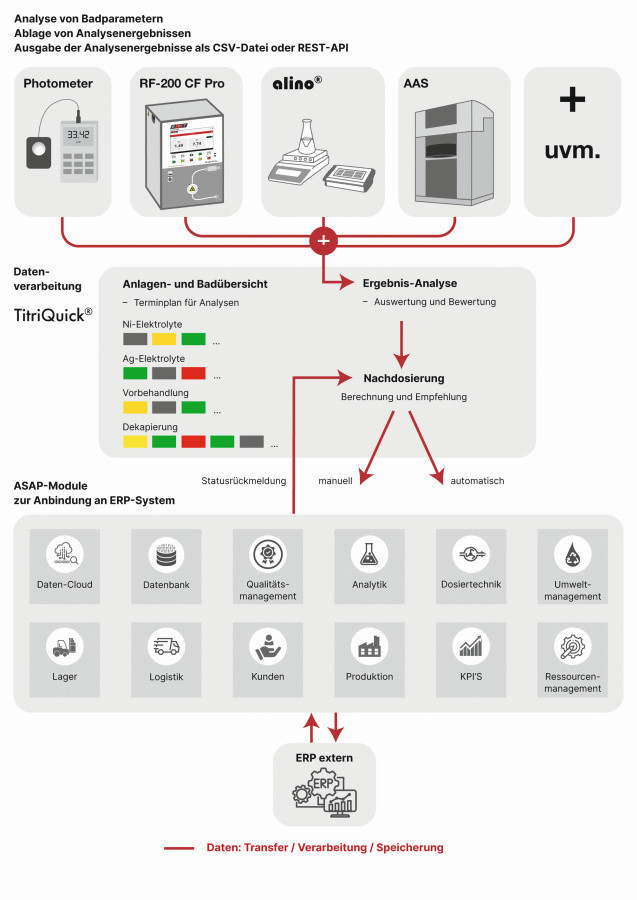

BAG Smart Analytics, a merger between the B+T Group and Gravitech GmbH, is currently developing intelligent, modular software. It is called ASAP (Analyzing System for Automated Processes). It combines experience and proven knowledge of surface coating, analytics, IT and production processes to create a holistic analysis tool for companies of all sizes and types. At the heart of ASAP is the software module for evaluating and assessing the analysis results. Regardless of the analysis method, the results are evaluated and correction options for both manual and automatic re-dosing are calculated and recommended. For automation, the subsequent control system, which controls the switching on of pumps, can also be connected and monitored via an interface (Fig. 5).

Fig. 5: ASAP, Analyzing System for Automated Processes, the intelligent, modular software for the analysis and correction of bath chemistry and the analysis of all operating processes in the company provides information and recommendations for action asap, as soon as possible

Fig. 5: ASAP, Analyzing System for Automated Processes, the intelligent, modular software for the analysis and correction of bath chemistry and the analysis of all operating processes in the company provides information and recommendations for action asap, as soon as possible

Digital transparency for quality assurance

With the data collected - whether automatically or manually - and the right software, the information is put into the correct context. A basic function of ASAP is the automated documentation of all processes and actions. This makes the processes transparent and complies with the current strict requirements for quality management and quality assurance.

RFID tracking in electroplating

What is in what quantities at what time and where? RFID technology is ideal for tracking exchangeable tanks, chemicals, critical spare parts and much more. Radio-Frequency Identification works battery-free with tags and readers according to the transmitter-receiver principle and directly records the digital movement of objects, independent of the human factor - language or qualification - and without administrative effort. The information is recorded and documented directly in the corresponding warehouse management software - also a planned module in ASAP.

Fig. 6: Agile production requires new tracking systems: a) The reader at the barrier recognizes the specific RFID of the tag on the tub and forwards the information b) to the software for further processing

Classic system configurations with permanently installed baths no longer meet today's requirements. For this reason, coating systems are modular in design so that individual tanks can be exchanged as required. The exchangeable baths with different contents are equipped with RFID sensor technology, which registers the exchange at the corresponding gate. The tracking of the individual tubs and the status of the respective contents are monitored via a database developed in-house for usage, analysis data, throughput and expiry date. This database is linked to the ERP system via an interface, checks the statuses against the orders for plausibility and informs the laboratory if baths are not used for a longer period of time that specific analyses, movement, etc. are required before they are released for use (Fig. 6a + b).

Big data

Digitization generates large amounts of data, the collection and management of which is extremely complex. Not every company can or wants to set up and manage its own IT infrastructure.

Due to a lack of expertise and a shortage of skilled workers, many companies are turning to cloud storage. Not only can data be stored here, but entire infrastructures can also be hosted. A critical point here is choosing the right provider. Of course, it is not easy to entrust your data to the big players from overseas with the corresponding data protection guidelines. It is therefore advisable to look for trustworthy hosting or cloud providers, especially in the region, that are subject to European data protection guidelines and ideally provide a responsible contact person.

With the emergence of large amounts of data and the creation of a large number of interfaces, hackers are also given access. Data must be protected against attacks because it is the company's most important asset.

Even if hardware and software are constantly kept up to date, employees are trained and interfaces to the outside world are well protected, there are still points of attack for cyber criminals. The solution to this can be a sophisticated back-up system (decentralization, outsourcing back-ups to a cloud).

New information and communication methods

Fig. 7: Here you can see both the web interface for employees (PC monitor) and B+T Future for customers, with order terminal (smartphone and tablet views) The streamlining of value chains in the logistics sector also means just-in-time delivery for surface coaters. Good communication internally with employees and externally with customers and suppliers is the be-all and end-all. In addition to traditional means such as telephone or email, there are also new methods of direct networking that are used depending on the application (direct access to the customer or supplier's network via VPN or even more secure blockchain solutions).

Fig. 7: Here you can see both the web interface for employees (PC monitor) and B+T Future for customers, with order terminal (smartphone and tablet views) The streamlining of value chains in the logistics sector also means just-in-time delivery for surface coaters. Good communication internally with employees and externally with customers and suppliers is the be-all and end-all. In addition to traditional means such as telephone or email, there are also new methods of direct networking that are used depending on the application (direct access to the customer or supplier's network via VPN or even more secure blockchain solutions).

Graphical user interfaces, so-called web interfaces, which can be displayed on almost all devices, bring transparency to the production process: order range, order status, plant utilization, shift schedules or vehicle fleet. Depending on the adaptation of the system and authorization level, the desired information can be brought to the employee or customer at any time and from anywhere in the world - and all without major installation effort or possible incompatibilities (Fig. 7).

VR / AR - Next Step

Where the visualization of data in the form of web interfaces reaches its limits, new technical possibilities such as AR (augmented reality) and VR (virtual reality) can be used. The production facility is transferred into a virtual environment, after which data from the plant control system can be read out about the status of process baths, for example, and transmitted to the employee in real time via a mobile device.

In this way, employees are shown key information about their tasks, such as checklists for maintenance activities, alarms, production lists, addition quantities and drum contents, directly at their workstation - another major step towards trouble-free and efficient production.

Strengthening employees' digital skills

Digitalization can help to reduce the complexity of processes. However, a changed awareness of how to use digital technologies is also required on the operating side. Blind faith in software and its supposed accuracy is the wrong approach, which is why machine and computer operators need to be trained for the new requirements and guided in their day-to-day work. There must be an understanding of the processes and the interrelationships of the data streams, because even a single input error can continue indefinitely. This requires specialist knowledge, but also the ability to think outside the box.

Training concepts will therefore also have to be adapted to the changing needs of professional life in the future. As an original coating company, B+T now has more trainees in IT than in the traditional coating professions.

Looking to the future: AI and machine learning

Of course, the topic of "artificial intelligence" cannot be left out of the current progress. In some areas, people no longer decide alone when and how production processes should run. AI and networked machines have long since arrived on the scene. They support people in making decisions or have already taken them over completely through automation, while software solutions provide management with increasingly complex evaluations. However, as discussed in the section "Networking machines via interfaces and energy management", surface technology is still in its infancy here.

B+T is also making its contribution to gaining knowledge in the KI-InGaTec research project and, with the RF-200 CF Pro from B+T K-Alpha, is providing data for the creation of algorithms for AI-based analytics and control.

Find out more at www.tu-braunschweig.de/iwf/nplce/forschungsprojekte/ki-ingatec

Achieving climate targets through digital networking

Effective planning and monitoring of production while taking energy use into account are important steps towards C02 control in manufacturing. Planning the order sequence is particularly important for energy-intensive production steps such as heat treatment or electroplating processes. If the data on energy consumption is recorded and monitored in parallel to planned production, potential savings and opportunities forCO2 reduction can be identified very quickly.

By consistently planning hardening sequences as part of hardening campaigns during heat treatment, for example, the number of article changes and the required temperature changes can be kept to a minimum. By evaluating the energy performance data, overlaid with the production data, gaps and peaks in energy utilization quickly become visible, which can either be closed or avoided.each component in production, whether raw, auxiliary or operating material, has its ownCO2 footprint. Digital tracking throughout the entire process allows their use to be designed efficiently and thecarbon footprint of the finished product to be determined automatically. This allows further optimization measures to be defined and their success to be evaluated. B+T has set itself the goal of achieving climate neutrality in production by 2026 - an ambitious goal that is being pursued at full speed.

Digitalization as an opportunity

There is no way around digitalization. It must be used effectively to reduce complexity in production chains (customer and supplier integration), optimize processes, use resources sparingly, increase flexibility and, last but not least, free up resources for customers and the core business.

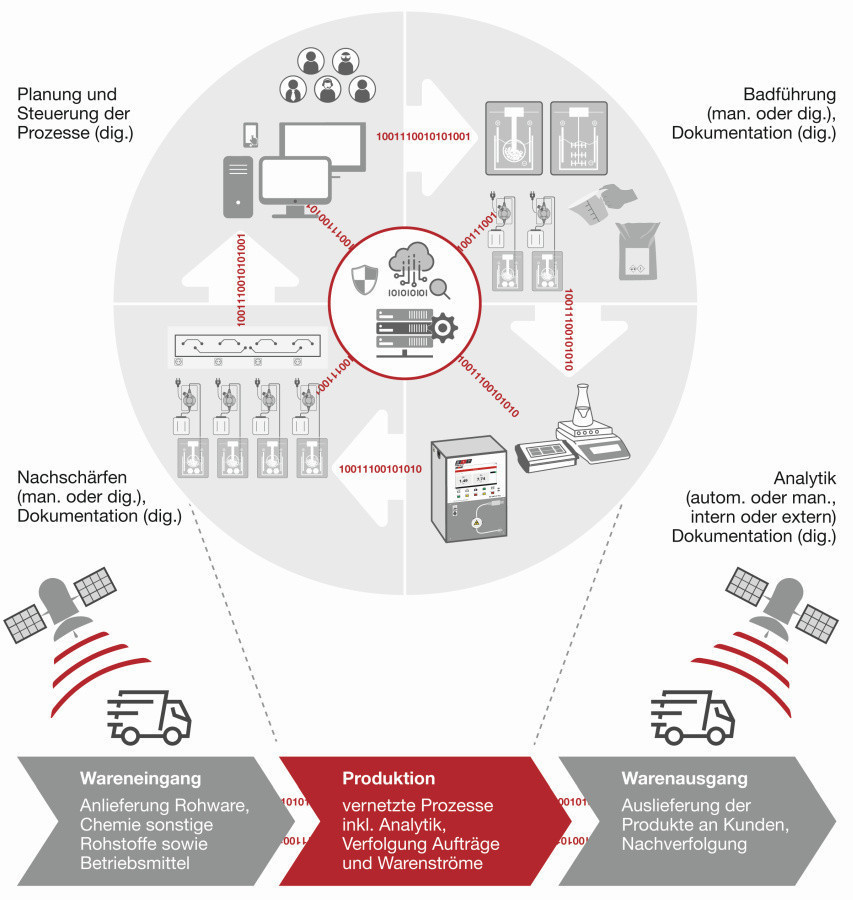

Fig. 8: Digitalization of the entire production process including analytics and automatic re-dosing

Fig. 8: Digitalization of the entire production process including analytics and automatic re-dosing

It is the central means of surviving international competitive pressure and meeting the demands of the future in terms of speed, efficiency and environmental orientation in production (Fig. 8).

www.bt-unternehmensgruppe.de

www.bag-analytics.de

www.gravitech.de

TO INFO

BeStPeri: Demand-oriented control of peripheral systems in production, funded by the Federal Ministry for Economic Affairs and Climate Protection.

FKZ: 03EI5008 (A)

EnOB: 3DEMO - Safe and energy-efficient factories through 3D emission monitoring; emission monitoring in surface technology and visualization approaches, funded by the Federal Ministry of Economics and Technology (BMWi).

FKZ: 03ET1660G.

KI-InGatec: AI-based inline measuring devices for electroplating technology, funded by the Federal Ministry of Education and Research.

FKZ: 01IS22014A-E.