Precious metal surfaces

Dr. Jürgen Hofinger (Biconex GmbH) presented a new technology for applying precious metal layers to plastic. Hofinger began by explaining that precious metal layers are generally used for reasons of electrical and/or catalytic properties. However, there are also niche markets with very specific requirements. Applications in medical technology were cited as an example. Disposable electrodes for ECGs are produced in the billions every year. Their electrical connections consist of silver-plated plastic elements. Precious metals are also used in contact lenses. Cleaning fluids ensure cleanliness during the night, especially for the so-called monthly lenses. The liquids must be activated using a platinum catalyst.

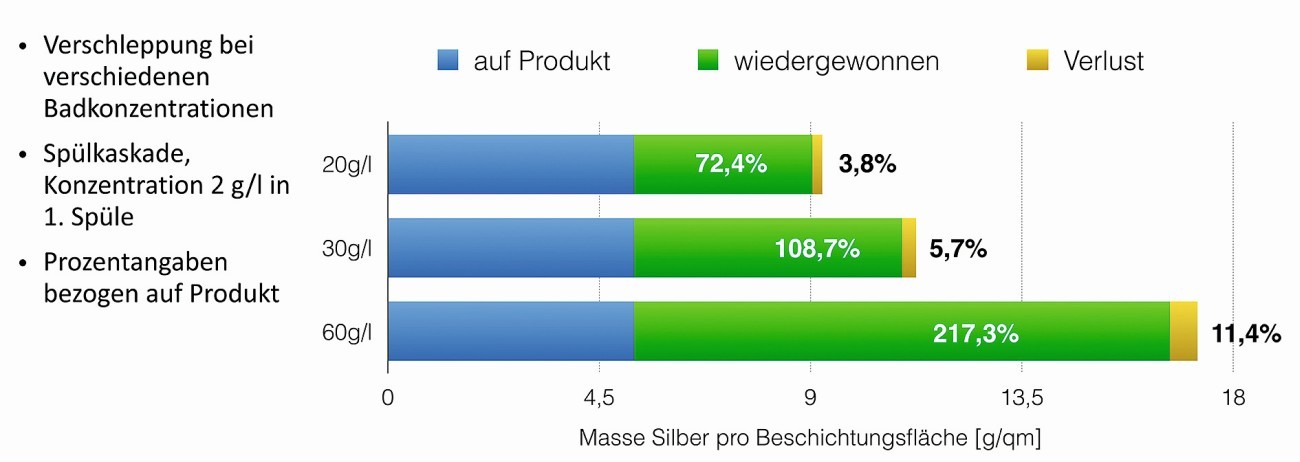

Precious metal losses from galvanic processes

Precious metal losses from galvanic processes

Conventional ink with nanoparticles (left) and particle-free ink produced in low-pressure plasma (right)Dr. Hofinger presented a new process from a Berlin start-up. The process is based on inks containing precious metals. Their special feature is that the precious metal salts can be reduced by a low-pressure plasma. This ensures compact layers with high conductivity.

Conventional ink with nanoparticles (left) and particle-free ink produced in low-pressure plasma (right)Dr. Hofinger presented a new process from a Berlin start-up. The process is based on inks containing precious metals. Their special feature is that the precious metal salts can be reduced by a low-pressure plasma. This ensures compact layers with high conductivity.

Oliver Brenscheid named various types of silver passivation. Which type is suitable? What properties are there? What do users need to consider? Brenscheid knew that the large number of variants and the high number of proper names make the market very confusing and also prevent suitable suppliers from being qualified. He therefore presented a project that aims to bring transparency to the silver passivation market. He also considers the precise definition of the tests to be important. This is because there are major differences in the regulations of the various manufacturers.

Process monitoring

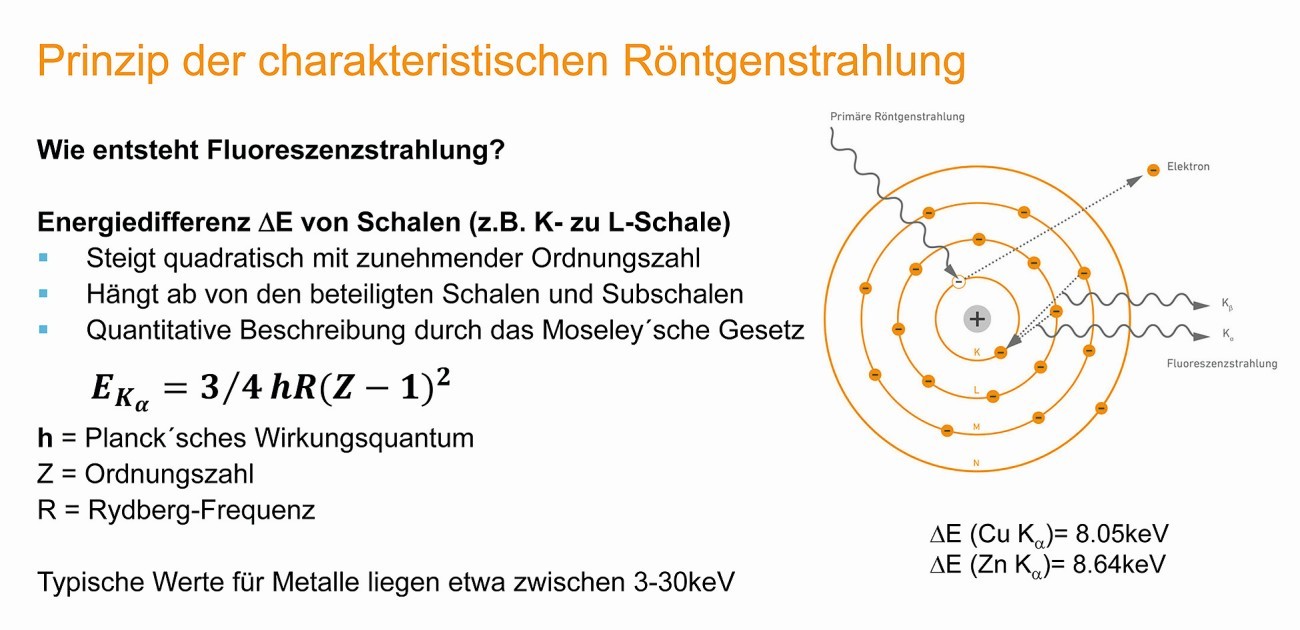

The use of polycapillary optics in X-ray fluorescence (XRF) coating thickness measurement has brought about a technical revolution, allowing the measurement of extremely thin coatings down to the nanometer range with a resolution of less than 20 µm, said Dr. Cay-Uwe Pinnow from Helmut Fischer GmbH.

Principle of characteristic X-ray radiation

Principle of characteristic X-ray radiation

In conjunction with (partial) automation, this enables the highly productive and cost-saving use of measurement technology for all common coating systems in the automotive, electronics and connector industries. There are also extended analysis options such as microscale homogeneity measurements in shape and element mappings.

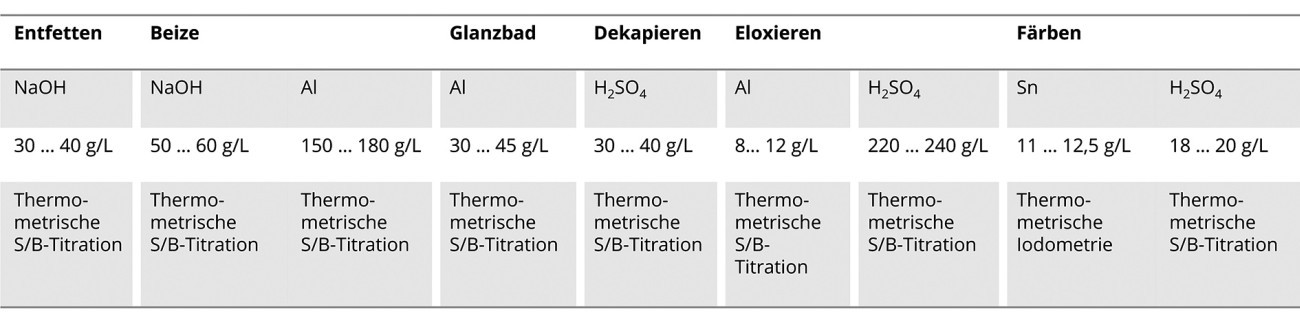

Daniel Schlak (Metrohm Prozessanalytik GmbH & Co. KG) called thermometric titration the key to success for process monitoring of galvanic electrolyte solutions. The high quality of the end product can only be guaranteed if the composition of the electrolytes used corresponds exactly to the manufacturer's specifications. Schlak used two case studies to explain the application of thermometric titration. In the first example, possible solutions for monitoring an anodizing plant were presented, while the second example showed the power of thermometry in monitoring a chrome plating plant.

Monitoring the bath parameters in an anodizing plant (application example 1)

Monitoring the bath parameters in an anodizing plant (application example 1)

Monitoring the parameters of a roughening process (application example 2)

Monitoring the parameters of a roughening process (application example 2)

The third presentation in this specialist area dealt with biofilms and algae in the water circulation system. See our detailed article in "Galvanotechnik" 11/2021, from page 1871.

News from standardization

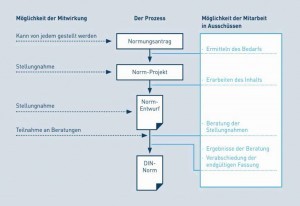

Rainer Paulsen and Janine Winkler from DIN Deutsches Institut für Normung e. V. presented the working committee NA 062-01-76 AA "Chemical and electrochemical coatings", which is responsible for the field of electroplating. The composition of the committee was presented, as well as its working methods. The working committee's current main projects are the revision of the following standards:

Rainer Paulsen and Janine Winkler from DIN Deutsches Institut für Normung e. V. presented the working committee NA 062-01-76 AA "Chemical and electrochemical coatings", which is responsible for the field of electroplating. The composition of the committee was presented, as well as its working methods. The working committee's current main projects are the revision of the following standards:

- DIN EN ISO 2080, "Metallic and other inorganic coatings" - Surface treatment, dictionary

- DIN EN ISO 12683, "Zinc coatings applied by mechanical cladding" - Requirements and test methods

In addition, new standardization projects would be developed on the following topics:

- Determination of the inhibitory effect of pickling inhibitors (Part 2)

- Prevention of hydrogen-induces brittle fracture of hingh-strength steel components

- Phosphate-free pretreatment of metals

- Chromium coatings from Cr(III)-based electrolytes on plastics

Dr. Jens Riedel later gave an outlook on the new DIN standard 50940 Part 2, Hydrogen embrittlement in pretreatment.

The lecture presented the procedure for creating the standard and gave an overview of the main chapters that could be derived from the first round robin test results.