Very different materials such as metals, glasses or plastics can be refined or functionalized with laser radiation, now for a variety of applications in industry or research. The virtual participants at this fourth LaP, organized by the Fraunhofer Institute for Laser Technology ILT in Aachen, came from the USA, Canada, China, Europe and other parts of the world. The focus of the event was on laser-based deburring and polishing, with topics including tumbling lasers, high-speed monitoring with AI support and 9-axis simultaneous processing.

Laser remelting optimizes light bundling

Fig. 2: Laser-polished sphere made of BK7 Dr. Dr. André Temmler, research associate in the Department of Mechanical Engineering at Tsinghua University, Beijing, kicked off the presentations at the first online conference. The former Fraunhofer ILT project manager demonstrated both high-speed images of laser remelting in brilliant quality and a new hybrid laser process for melt structuring. A CW laser (focus: 560 μm) generates a melt pool and a second pulsed laser (focus: 17 μm) vaporizes and deforms the melt pool surface due to the vapour pressure. However, his reports on experiments with the standard process were also exciting: the focus was on the laser polishing of tool steel H11. Roughnesses of Ra 0.05 μm are possible under laboratory conditions. The key to this is the right choice of process parameters and shielding gas.

Fig. 2: Laser-polished sphere made of BK7 Dr. Dr. André Temmler, research associate in the Department of Mechanical Engineering at Tsinghua University, Beijing, kicked off the presentations at the first online conference. The former Fraunhofer ILT project manager demonstrated both high-speed images of laser remelting in brilliant quality and a new hybrid laser process for melt structuring. A CW laser (focus: 560 μm) generates a melt pool and a second pulsed laser (focus: 17 μm) vaporizes and deforms the melt pool surface due to the vapour pressure. However, his reports on experiments with the standard process were also exciting: the focus was on the laser polishing of tool steel H11. Roughnesses of Ra 0.05 μm are possible under laboratory conditions. The key to this is the right choice of process parameters and shielding gas.

Laser polishing of tools

Dr. Evgueni V. Bordatchev, team leader at the National Research Council of Canada in London (Ontario), explained how intricately shaped surface structures of tools for PMMA headlights can be precisely tailored using a laser. The German-Canadian joint project modified the laser remelting process as an alternative to the previous structuring process using diamond tools: together with the Fraunhofer ILT and RWTH Aachen University, it was possible to structure tool inserts made of 1.2343 using a 100 W laser in such a way that a sufficiently homogeneous light distribution and decoupling efficiency could be achieved.

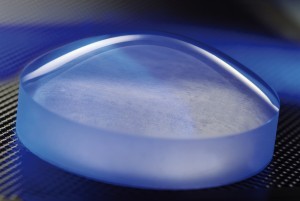

Fig. 3: Laser-polished asphere made of glass Dr. Hemmo Touvinen from the North Karelia University of Applied Sciences in Joensuu, Finland (University of Eastern Finland) dealt with the laser polishing of metal surfaces that were processed with ultra-precision using diamond tools. Investigations on chemically deposited nickel showed that periodic structures caused by the diamond tool can best be removed with Nd:YAG lasers (1064 nm) at pulse durations of 7 ns. However, the surface roughness increased to 40 nm.

Fig. 3: Laser-polished asphere made of glass Dr. Hemmo Touvinen from the North Karelia University of Applied Sciences in Joensuu, Finland (University of Eastern Finland) dealt with the laser polishing of metal surfaces that were processed with ultra-precision using diamond tools. Investigations on chemically deposited nickel showed that periodic structures caused by the diamond tool can best be removed with Nd:YAG lasers (1064 nm) at pulse durations of 7 ns. However, the surface roughness increased to 40 nm.

The Shenzhen Institute of Information Technology in China has also developed an advantageous form of hybrid technology. Scientist Dr. Bowei Luo reported on the use of a permanent magnetic field in the laser polishing of tool steel. Without a magnetic field, the Q-switched solid-state laser with a power of 400 W and a maximum laser beam width of 0.54 mm achieved a roughness Ra of 0.514 μm, which improved significantly to 0.168 μm with a magnetic flux density of 0.4 T. Tests have shown that the polishing effect improves even at much weaker magnetic fields, but a flux density of 0.4 T appears to be optimal. Higher values have not yet led to better results.

Targeted polishing of glass

Manuel Jung, a research associate from Willenborg's team at Fraunhofer ILT, presented a hybrid process for optical lenses, among other things. Together with the Deggendorf Institute of Technology, the Aachen-based team analyzed how costs and time can be optimized in the production of glass optics in the HyoptO project. The process consists of pre-grinding, laser polishing and final mechanical correction polishing. ACO2 CW laser(wavelength: 10,600 nm, 1 kW) was used. Laser polishing (10 s for a lens with a diameter of 30 mm) significantly reduced the time required for the final mechanical polishing. The results are impressive, as the hybrid process has already reduced the processing time for standard lenses made of borosilicate crown glass (NBK7) by 29% and for optical quartz glass by 63%. 2+3

"Wobbling" laser: roughness reduced by more than 60 percent

Fig. 4: Laser-polished active surface section of a slide for die casting © The University of Wisconsin-Madison and the Bremen Institute for Applied Beam Technology BIAS have made the laser beam tumble. US scientist Patrick J. Faue presented trochoidal laser polishing, in which the superimposition of spiral and circular movements causes the beam to virtually tumble. A maximum 30 W fiber laser (wavelength: 1070 nm, laser focus diameter: 150 μm) polished 316L stainless steel at a feed rate of 30 mm/s. The German-American team investigated how three different tumbling beams (range: 1 to 15 μm) affect the result. Interestingly, all three wobble types reduced the roughness Ra by more than 60 percent. However, process artifacts do occur, for example in the form of surface waviness.

Fig. 4: Laser-polished active surface section of a slide for die casting © The University of Wisconsin-Madison and the Bremen Institute for Applied Beam Technology BIAS have made the laser beam tumble. US scientist Patrick J. Faue presented trochoidal laser polishing, in which the superimposition of spiral and circular movements causes the beam to virtually tumble. A maximum 30 W fiber laser (wavelength: 1070 nm, laser focus diameter: 150 μm) polished 316L stainless steel at a feed rate of 30 mm/s. The German-American team investigated how three different tumbling beams (range: 1 to 15 μm) affect the result. Interestingly, all three wobble types reduced the roughness Ra by more than 60 percent. However, process artifacts do occur, for example in the form of surface waviness.

Laser polishing of 3D printed components

The increase in additively manufactured components also influenced the content of LaP 2020. Professor Yingchun Guan, Beihang University in Beijing, presented methods for laser polishing metallic 3D printed components, which were created using laser powder bed fusion (LPBF), a laser-based 3D printing process in a powder bed. The institute had positive experiences with titanium and nickel alloys (Inconel 718), among others, whose roughness Ra could be reduced from more than 10 µm to less than 0.1 μm. Turbine components, so-called blades, were polished with high efficiency (100 to 400 cm2/h). Polishing increased hardness and wear resistance by 25 to 40 percent.

Lucas-Hermann Beste, scientist at the Bremen Institute for Applied Beam Technology BIAS, in collaboration with the University of Wisconsin-Madison, USA, investigated how the porosity of near-surface layers in LPBF components can be reduced by laser polishing. An experiment with a cobalt-chromium alloy (CoCr), a material often used in medical technology, showed how this can be achieved. Under argon shielding gas, a Q-switched 35 W solid-state laser (1080 nm) laser polished a small CoCr cube with a 120 μm laser beam and a feed rate of 120 to 200 mm/s. The porosity was reduced by up to 63 percent and the roughness Sa by around 75 percent to an average of 2 μm.

Polishing tools and molds

Fig. 5: Machine tool for laser polishingToolsand molds are among the most demanding components, as polishing determines the subsequent quality and appearance of the corresponding products. Due to the challenging geometry, Laura Kreinest, a member of staff at the Chair of Digital Additive Production DAP at RWTH Aachen University, explained how the laser process can be adapted to the often very uneven processing paths. She demonstrated this using a tool made of GGG40, which is used to produce glass flacons. Three process strategies were considered: laser polishing with 5+3, 8 or 9-axis processing. For complex geometries, 9-axis simultaneous machining is particularly advantageous, as CAM-NC path planning in workpiece coordinates is possible here. The use of a CAM-NC data chain (e.g. Powermill, Technology Processor TP4, LasPC), which was developed by Fraunhofer ILT, has proven its worth here. Laser polishing was demonstrated on a machine from Maschinenfabrik ARNOLD in Ravensburg. The machine is designed for components weighing up to 100 kg and a maximum diameter of 450 mm.

Fig. 5: Machine tool for laser polishingToolsand molds are among the most demanding components, as polishing determines the subsequent quality and appearance of the corresponding products. Due to the challenging geometry, Laura Kreinest, a member of staff at the Chair of Digital Additive Production DAP at RWTH Aachen University, explained how the laser process can be adapted to the often very uneven processing paths. She demonstrated this using a tool made of GGG40, which is used to produce glass flacons. Three process strategies were considered: laser polishing with 5+3, 8 or 9-axis processing. For complex geometries, 9-axis simultaneous machining is particularly advantageous, as CAM-NC path planning in workpiece coordinates is possible here. The use of a CAM-NC data chain (e.g. Powermill, Technology Processor TP4, LasPC), which was developed by Fraunhofer ILT, has proven its worth here. Laser polishing was demonstrated on a machine from Maschinenfabrik ARNOLD in Ravensburg. The machine is designed for components weighing up to 100 kg and a maximum diameter of 450 mm.

Real-time monitoring for quality control

The quality of the laser polishing process can be increased, given the large number of influencing parameters, if the process is monitored with a view to process reliability: Jack Anthony Beyfuss, Associate Professor and Director of Research University of Western Ontario, London (Canada) relies on real-time thermographic monitoring and AI software. A Tachyon MWIR camera system recorded the operation of polishing lasers (5 to 35 W) at 3000 frames per second (64x64 pixels) in order to reduce the enormous amount of data generated with the help of MATLAB analysis software, among other things, for the purpose of efficient further processing. According to Beyfuss, the analysis of the pattern recognition made it possible to select the most suitable information features. He closed the control loop with the help of an AI program that works according to the principle of machine learning in conjunction with a Bayesian network.

Conclusion:

Initiator and moderator Willenborg from Fraunhofer ILT concluded with a satisfied conclusion: "LaP number four had to take place virtually, but the premiere worked out great. I look forward to seeing the international laser polishing community again at the fifth LaP, which will hopefully take place live in Aachen again in 2022."