A key issue when designing a new product is the choice of suitable materials. Each material group has special properties that are decisive for the function and design of individual assemblies. The challenges that arise when manufacturing and processing these different materials are as varied as the materials themselves. Particularly in the area of adhesion, it sometimes takes some experience coupled with a scientific approach to achieve the necessary quality in processes such as bonding, printing, painting, coating, overmolding or potting.

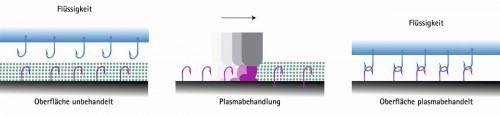

Plastics are a typical group of materials for which adhesion processes are not possible in many cases without suitable pre-treatment. Quite a few representatives of this group are characterized by highly hydrophobic surface properties, which are reflected in a low surface energy and lead to poor wettability and adhesion. The reason for this is the lack of suitable molecular groups on the plastic surface that could interact with those of a binding partner. By treating these surfaces with atmospheric pressure plasma, precisely these "anchor groups" are created and are available for the subsequent adhesion process (Fig. 1).

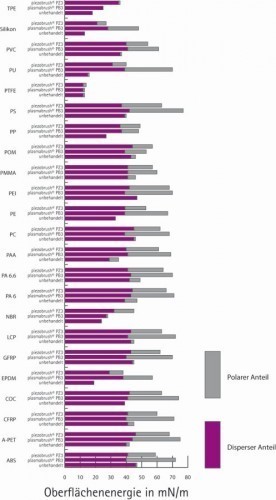

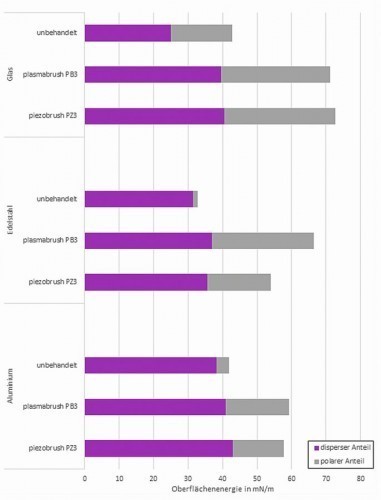

As soon as these groups are saturated by a bonding partner, e.g. adhesive, they serve as a guarantee for a long-term stable bond. Chemically, this so-called activation of the surface with atmospheric pressure plasma is an enrichment of the plastic with polar, oxygen-based molecular groups. This is reflected in an increase in the polar component of the surface energy, which is made up of the sum of the polar and disperse components. Figure 2 compares these two proportions of the surface energies of various plastics in their untreated state with those after treatment with two different atmospheric plasma systems.

Fig. 2: Surface energy of various plastics before and after treatment with the plasmabrush® PB3 high-performance plasma system (speed 200 mm/s, process gas: compressed air) and the piezobrush® PZ3 cold plasma hand-held device (speed 20 mm/s, process gas: ambient air)

Fig. 2: Surface energy of various plastics before and after treatment with the plasmabrush® PB3 high-performance plasma system (speed 200 mm/s, process gas: compressed air) and the piezobrush® PZ3 cold plasma hand-held device (speed 20 mm/s, process gas: ambient air)

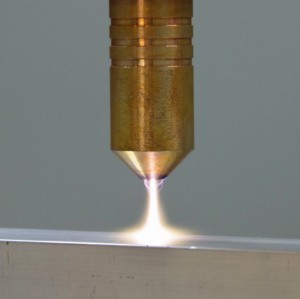

Fig. 3: plasmabrush® PB3 high-performance plasma systemThehigh-performance plasmabrush® PB3 system is a conventional plasma jet that can be operated with compressed air, nitrogen and other process gases and is designed for high process speeds for line integration with an output of approx. 1 kW (Fig. 3).

Fig. 3: plasmabrush® PB3 high-performance plasma systemThehigh-performance plasmabrush® PB3 system is a conventional plasma jet that can be operated with compressed air, nitrogen and other process gases and is designed for high process speeds for line integration with an output of approx. 1 kW (Fig. 3).

The piezobrush® PZ3 cold plasma hand-held device, on the other hand, requires only 18 W of power and is primarily used in prototype and small series production.

Figure 2 shows that both plasma systems can improve the surface energies of most plastics, particularly increasing the previously low polar component. The surface energy is therefore also used as a parameter for evaluating the effectiveness of plasma treatments. In many cases, it is also a good indicator of the success of a subsequent adhesion process. There are now even recommendations from adhesive or printing ink manufacturers regarding the surface energies that the substrates should have. However, it is not only the ratio of the polar and disperse components that is important here, but also the basic compatibility of the two bonding partners. For example, a metal-curing adhesive will not bond to a highly wettable plastic. Conversely, it is also possible that a plasma treatment, as in the case of PTFE in Figure 2, does not appear to bring about any significant change in the surface energy, but nevertheless leads to improved adhesion. This is clearly illustrated by the example of inkjet printing on the same material (Fig. 4).

Fig. 4: Inkjet printing on untreated (left) and plasma-treated (right) PTFE

Fig. 4: Inkjet printing on untreated (left) and plasma-treated (right) PTFE

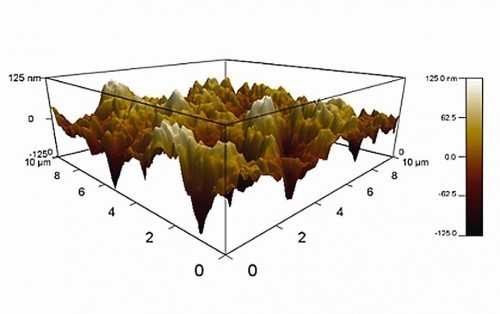

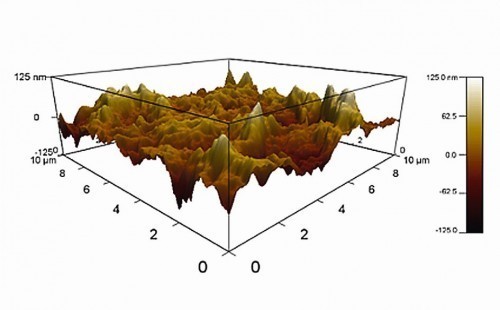

Investigations with the atomic force microscope indicate that treatment with the piezobrush® PZ3 (Fig. 5) results in a slight roughening of the PTFE surface from a mean roughness value of 21 nm to 26 nm after treatment (source: Oliver Beier, Andreas Pfuch, INNOVENT e.V. Technologieentwicklung, Beta test report piezobrush PZ3, 2020). As a result, the tensile strength of an adhesive bond with the DP460 adhesive was multiplied from 0.14 MPa to 0.65 MPa on these samples in a tensile test according to DIN EN ISO 4625.

Far from idealized laboratory conditions, there are further challenges in adhesion processes in real production. For example, the plastic parts themselves often come from manufacturing processes in which additives such as coolants, lubricants or release agents are used. These organic impurities often remain on the surfaces in very thin layers and prevent the material surface from coming into contact with its selected bonding partner at all. Even a few layers of molecules can lead to considerable quality problems. This effect affects not only plastics, but in fact all materials that are used and processed in production. Here too, pretreatment with atmospheric pressure plasma can lead to an improvement in process and product quality. The highly reactive species in the plasma oxidize these thin organic separating layers and thus remove them from the surface (Fig. 6). In the case of glass or metal, for example, this exposes existing bonding groups on the material surface and makes them available again for adhesion processes. This effect also manifests itself in the surface energy, as the organic layers typically have a hydrophobic character. The removal of these organics reveals the surface properties of the actual substrate surface. Figure 7 illustrates this using the example of glass, stainless steel and aluminum.

Fig. 6: Fine cleaning of surfaces by plasma treatment

Fig. 6: Fine cleaning of surfaces by plasma treatment

Fig. 7: Surface energy of glass, stainless steel and aluminum before and after treatment with the plasmabrush® PB3 high-performance plasma system (speed 200 mm/s, process gas: compressed air) and the piezobrush® PZ3 cold plasma hand-held device (speed 20 mm/s, process gas: ambient air)

Fig. 7: Surface energy of glass, stainless steel and aluminum before and after treatment with the plasmabrush® PB3 high-performance plasma system (speed 200 mm/s, process gas: compressed air) and the piezobrush® PZ3 cold plasma hand-held device (speed 20 mm/s, process gas: ambient air)

Although the untreated surfaces were thoroughly cleaned with isopropanol and blown off with clean compressed air before measuring the surface energy, there was a significant improvement in wettability after the respective plasma treatments. This plasma-induced fine cleaning process can be impressively demonstrated using fluorescence measurement technology (source: Stefan Büttner, Lutz Freudenberg, SITA Messtechnik GmbH, beta test report piezobrush PZ3, 2020). A stainless steel sheet specifically contaminated with Fuchs Anticorrit MRK 4 oil is treated in two discrete areas with the piezobrush® PZ3 cold plasma handheld device using the "Nearfield" module. This module has been specially developed for use on conductive substrates. The entire sheet is then scanned in high resolution with the SITA FluoScan 3D using fluorescence measurement in order to examine the distribution of the oil on the sheet (Fig. 8).

Fig. 8: Test setup piezobrush® PZ3 and SITA FluoScan 3D

Fig. 8: Test setup piezobrush® PZ3 and SITA FluoScan 3D

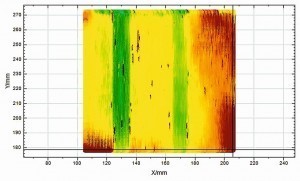

Fig. 9: Fluorescence measurement of the stainless steel plateThefluorescence measurement is a layer thickness-sensitive measurement and records the fluorescence intensity in RFU (relative fluorescence unit). The lower the measured value in RFU, the cleaner the surface. This method shows a clear reduction in the RFU value in the plasma-treated areas.

Fig. 9: Fluorescence measurement of the stainless steel plateThefluorescence measurement is a layer thickness-sensitive measurement and records the fluorescence intensity in RFU (relative fluorescence unit). The lower the measured value in RFU, the cleaner the surface. This method shows a clear reduction in the RFU value in the plasma-treated areas.

The intensity of the plasma treatment can also be assessed here and brought into direct correlation with the treatment speed. The more intensive cleaning takes place at a speed of 2.5 mm/s (left track), but the cleaning effect is also clearly recognizable at twice this speed (right track) (Fig. 9).

The heat input of the high-performance plasmabrush® PB3 system can be an additional advantage in such fine cleaning processes on materials that are not very temperature-sensitive. While the temperature input from the plasma flame should be avoided for plastics, for example, by means of defined treatment intervals and relatively high process speeds, this can be used for the fine cleaning of inorganic materials. At higher temperatures, chemical processes run faster, including the oxidation of organic impurities. In addition, the decomposition products can be evaporated better and thus removed from the surface more quickly. However, the use of the plasmabrush® PB3 system is not limited to organic contaminants. By selecting a hydrogen-containing process gas, such as forming gas 95/5, oxides on the surface are also reduced and removed. This is where a special feature of the plasmabrush® PB3 system comes into play - the unipolar pulsed arc. In normal operation, this is only used to excite the process gas passing by it, which is then used as a diffuse plasma flame to activate plastics, for example. In the case of conductive substrates, however, this arc can be transferred to the surface if it is earthed. This allows a much more intensive treatment of the surface, in which non-conductive layers such as oxides are broken through and at the same time the high-frequency impacts of the arc result in a slight roughening of the surface (Fig. 10, 11).

Fig. 10: Transferred arc on stainless steel

Fig. 10: Transferred arc on stainless steel

This special type of oxide removal is used in roll cladding, for example, but it also has an impressive effect in sealing and bonding applications, even without the use of special gases. For example, when using compressed air as a process gas, the plasmabrush® PB3 system only develops its full effect on stainless steel in the transferred arc mode. When evaluating a silicone seal, it was found that it demonstrated significantly better adhesion properties in the climate change test if the stainless steel surface was pre-treated with the transferred arc beforehand. Although a standard treatment with the diffuse secondary plasma initially led to an improvement in adhesion compared to the untreated case, it was unable to pass the intensive resistance tests.

Fig. 11: Removal of oxide layer on copper alloy with the plasmabrush® PB3 system (process gas: forming gas 95/5)

Fig. 11: Removal of oxide layer on copper alloy with the plasmabrush® PB3 system (process gas: forming gas 95/5)

The challenges for adhesion processes may be many and varied depending on the material. Atmospheric pressure plasma technologies offer a pragmatic and environmentally friendly solution for the majority of applications. Not only can surface properties be optimized on a wide variety of materials for a wide range of subsequent processes, the various technologies also offer a tailored solution for the respective process chain. From the manual application of cold plasma for prototype construction (Fig. 12), through use in small series production, to fully automated line integration for large quantities - the choice of suitable technology and the modularity of the piezobrush and plasmabrush system exploit the optimization potential in all areas.

Fig. 12: Plasma in 3D printing

Fig. 12: Plasma in 3D printing

Even if a pre-treatment step was not taken into account in the original design of the process or even the production system, the compact design of the plasma systems allows uncomplicated retrofitting. For example, when changing materials, a complicated search for and qualification of a new adhesive or sealant can be avoided by implementing plasma pre-treatment. Such a pre-treatment step is also used in the area of quality assurance to compensate for the fluctuating surface quality and cleanliness of purchased parts, for example. New innovative plasma technologies such as the PDD® technology used in piezobrush are also becoming increasingly established in the modern manufacturing industry.