In a research project, aluminum oxide coatings were applied to stainless steel surfaces using atmospheric cold plasma spraying, whereby the mechanical and intrinsic coating properties were investigated as a function of the plasma power. Result: With increasing power, a reduction in porosity as well as an increase in hardness and abrasion resistance is achieved. In addition, maximum adhesive strength values of 13 MPa were achieved.

In modern materials science and technology, the targeted modification of surface properties is playing an increasingly important role. With the ever-increasing demand for performance, durability and functionality of new materials, the optimization of their surfaces is becoming a decisive challenge and at the same time a source of innovative solutions. Plasma spraying is one of the most frequently used variants of thermal spraying and is the preferred method in industries such as the automotive, paper, aerospace and aviation industries to produce corrosion and wear-resistant [1, 2] and thermally insulating [3] coatings. Aluminum oxide is a widely used coating system. Plasma-sprayed coatings are created by the layer-by-layer build-up of fused-on particles that hit the substrate at high speed, flatten and harden there. The plasma spraying process is highly complex and is influenced by many different variables. Up to 200 influencing variables are listed in the literature [4], which is why the control or correct setting of the process parameters is crucial in order to meet the high demands on coating quality.

Atmospheric cold plasma spraying, a special form of plasma spraying, is characterized by the use of small particle sizes of the spray additives in the range of 10 to 20 µm. This enables the powder to be melted at lower power levels of 2 to 15 kW compared to atmospheric plasma spraying (APS), which requires power levels of 20 to 200 kW. Due to the resulting lower plasma temperatures, cold plasma spraying is also suitable for coating substrates with low temperature resistance. For example, in our own studies, cold plasma spraying was used to successfully produce hydroxyapatite coatings to increase the bioactivity of polyether ether ketone (PEEK) as a bone replacement material [5] as well as copper spray coatings on carbon fiber reinforced plastic (CFRP) for aerospace applications [6]. Furthermore, porous, adhesive copper spray coatings with antimicrobial properties could be applied to stainless steel [7].

This article is dedicated to the production and characterization of aluminium oxide coatings using cold plasma spraying. In addition to the coating thickness and morphology, the microhardness, porosity, adhesive strength and abrasion resistance are analyzed as a function of the plasma power used.

Production of aluminum oxide coatings

The coatings were applied to flat stainless steel substrates 1.4301 (X5CrNi18-10, LT Blechbau GmbH & Co. KG) of various dimensions (100x100x1 mm3, 50x50x1 mm³ and 20x20x1 mm3). The substrate material was mechanically roughened to create an adhesion base for the sprayed layers. The sandblasting process was carried out using a basic quattro IS fine blasting unit from Renfert GmbH. The abrasive used was angular corundum powder (Hasenfratz GmbH) with an average particle size of 130 µm. The average roughness value Sa achieved after sandblasting was between 2 and 2.5 µm. The roughened substrates were then cleaned with isopropanol/ethanol (ratio 1:1) in an ultrasonic bath for about 10 minutes and dried with compressed air.

The aluminum oxide coatings were produced on a current-controlled cold plasma spraying system InoCoat 3 from Inocon Technologie GmbH. The plasma head is equipped with a rotationally symmetrical copper anode and a tungsten cathode tip. Both electrodes are arranged centrally to each other. The cold plasma spraying system can be operated up to a maximum power of Pmax= 12.5 kW and therefore uses significantly lower power than conventional atmospheric plasma spraying systems. A plasma is generated on the basis of an electrical discharge and the ionization of the working gas (argon). The thermal expansion of the plasma and its escape through the open end of the nozzle creates a plasma jet that is directed towards the substrate. Spray additives in the form of powders are used in the plasma spraying process. Melting the powder particles in the plasma and spinning them onto a moving substrate creates a spray coating.

An angular precious corundum powder F500 (Kuhmichel GmbH) with an Al2O3 purity of 99.7 % was used as the spray additive. According to the manufacturer, the D50 particle size distribution is D50 = 12.8 ± 1.0 µm. When applying the coatings, the current intensity and the number of coating passes (DL) were varied. The voltage was automatically readjusted depending on the condition of the electrodes and was between 24-25 V during the coatings. A constant value was selected for all other parameters. The adjustable process parameters are shown in Table 1. During the coating process, the flat substrates mounted on the traversing table were moved in a meandering pattern under the plasma head using an X-Y surface gantry EXCM-30 from Festo Vertrieb GmbH & Co. The resulting substrate temperatures were between 150 and 400 °C, depending on the plasma power. Following the coating process, loose powder particles were removed by treatment in an ultrasonic bath with isopropanol/ethanol (ratio 1:1) and subsequent drying with compressed air.

Parameters | Unit | Setting value | |

constant | Process gas flow (argon) | l-min-1 | 10 |

Carrier gas flow (argon) | l-min-1 | 10 | |

Powder feed rate | g-min-1 | 3 | |

Spray distance | mm | 50 | |

Travel speed of the substrate | mm-s-1 | 200 | |

Grid / offset | mm | 5 / 2,5 | |

variable | Amperage | A | 350-500 |

Coating passes | - | 4-10 |

Tab. 1: Investigated process parameters

Various analytical methods were used to investigate the coating properties. The coating thickness of the spray coatings as well as the roughness of the spray coatings and the sandblasted substrate materials were determined using a MarSurf CM explorer confocal microscope from Mahr GmbH. By masking the substrate, a defined layer step could be created during the coating process. The coating thickness was measured along this step at nine different measuring positions per sample. Topographic images of the coating structure were taken using a SUPRA 55VP scanning electron microscope (SEM) from Carl Zeiss Microscopy GmbH. The porosity was assessed by grey-scale analysis based on the evaluation of ten light microscopic cross-sectional images each with a magnification factor of 500, taking care to ensure that the analyzed areas were adjacent to each other but did not overlap. Subsequently, the porosity was determined using the 2D image processing software ImageJ based on the gray values of dark pores and light matrix. In addition, Vickers microhardness measurements were carried out on the prepared cross-sections in accordance with DIN EN ISO 6507-1 using a Carat 930 hardness tester from ATM GmbH. The test load was 0.981 N (HV0.1) with a load time of 15 seconds. Ten measured values were determined for each sample. The adhesive strength was examined by means of a punch tear-off test based on DIN EN ISO 4624. The stainless steel stamps were sandblasted, flamed with Pyrosil and pre-treated with a primer SuraLink 021 (Sura Instruments GmbH). The stamps and test specimens were then bonded (Scotch-Weld DP460) and cured at 65 °C for 2 hours. The adhesive strength was determined on five bonded specimens using an inspekt table 50 kN universal testing machine from Hegewald und Peschke.

Finally, the abrasion resistance of the aluminum oxide coatings was tested using the Taber Abraser test (Taber Abraser 5131, Erichsen GmbH) in accordance with DIN ISO 9352, using Calibrader rolls of type H18 (coarse abrasion) and an additional weight of 250 g. The abrasion was measured using a weighing machine. The abrasion was determined by weighing in mg after 100 or 200 revolutions of the test specimen under the friction wheels. The test ended as soon as the layer was penetrated and the substrate material was visible.

Influence of the plasma power on the coating properties

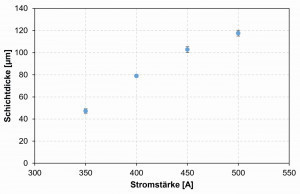

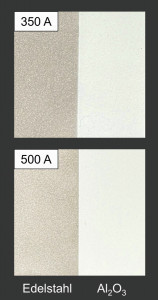

The aluminum oxide coatings produced on stainless steel showed a light gray to white color (see Fig. 1, right). The coating thickness was first measured on the coatings using optical profilometry. Within the investigated process parameters, coating thicknesses between 47 and 118 µm could be generated. These are shown in Figure 1 as a function of the current intensity. An increase in coating thickness can be observed as the current increases from 350 to 500 A.

The plasma enthalpy or temperature increases with increasing current intensity. Consequently, the average degree of melting of the particles increases, as a result of which a larger proportion of particles are melted and deposited as a layer on the substrate. In addition to the coating thickness, the roughness of the coatings was analyzed using confocal microscopy over an area of 1.6 x 0.8 mm2. Depending on the parameters, an arithmetic roughness Sa between 3.1 and 3.7 µm was obtained. It was observed that the roughness decreases slightly with increasing power.

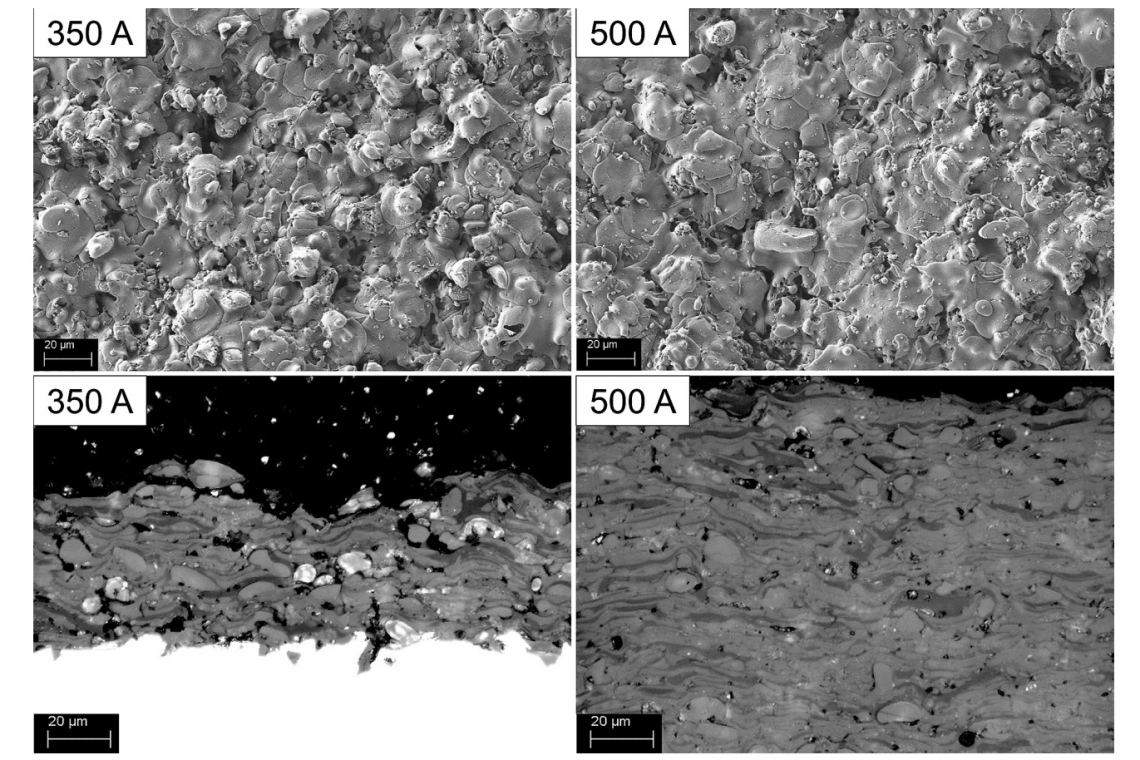

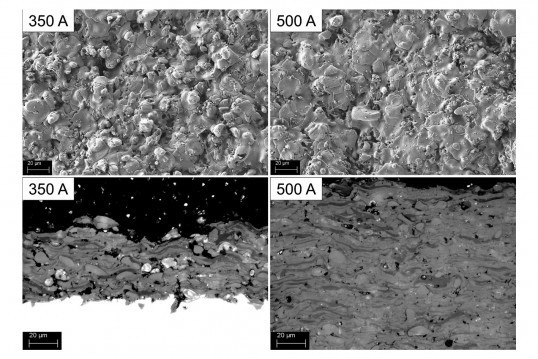

Figure 2 shows examples of two scanning electron micrographs and light microscopic cross-sectional images of spray coatings produced at 350 and 500A. The images show rough structures and the layered structure of fused particles ("splats") as characteristic features of spray coatings. There are numerous pores between the particles in the coating, which can contribute to the formation of an open pore network. Depending on the plasma power, there are differences in the degree of melting of the individual particles. At high currents (500 A), the particles are melted considerably. This manifests itself in large and strongly flattened splats (see Fig. 2, right). In contrast, at low amperage (350 A), a larger proportion of unmelted or only partially melted particles can be seen on the surface, leading to a slightly increased roughness in comparison. Fig. 2: SEM images (top) and light microscopic cross-sectional images (bottom) of aluminium oxide spray coatings at different amperages 350 A (left), 500 A (right)

Fig. 2: SEM images (top) and light microscopic cross-sectional images (bottom) of aluminium oxide spray coatings at different amperages 350 A (left), 500 A (right)

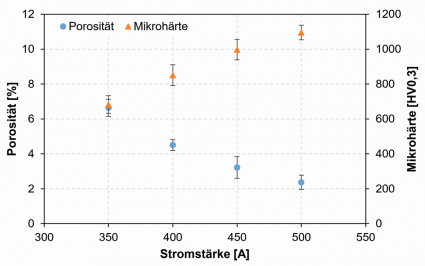

The porosity of the spray coatings was quantified using a gray value analysis and is shown in blue in Figure 3 as a function of the electrical current. A clear decrease in porosity from approx. 7 to 2.5 % can be observed with increasing amperage. This observation can be confirmed on the basis of various literature sources [8, 9] on plasma-sprayed coatings. The increased degree of melting of the powder particles with increasing plasma temperature improves the adaptability of the forming splats to the surface topography of the substrate and results in lower porosity. In the case of low degrees of melting, the proportion of interlamellar pores increases due to small contact areas between the deposited particles (see Fig. 2 below).

The microhardness HV0.1 is an important indicator for the mechanical properties of plasma-sprayed coatings. In Figure 3, shown in orange, it can be seen that the microhardness increases with increasing current strength from around 700 to 1100 HV0.1. This increase in microhardness may be due to improved melting of the particles in the coating, which is achieved with higher amperages. The results also show that the hardness of the coatings is strongly influenced by the amount of porosity. Higher porosity can lead to a reduction in hardness as the voids or pores affect the strength and density of the coating. In his work [10], Sarikaya investigated the influence of other parameters, such as spray distance and substrate temperature, on the microhardness and porosity of atmospheric plasma-sprayed aluminum oxide coatings. It was shown that the microhardness runs in the opposite direction to the porosity depending on the parameters investigated. Fig. 3: Porosity (blue) and microhardness (orange) as a function of the electrical current

Fig. 3: Porosity (blue) and microhardness (orange) as a function of the electrical current

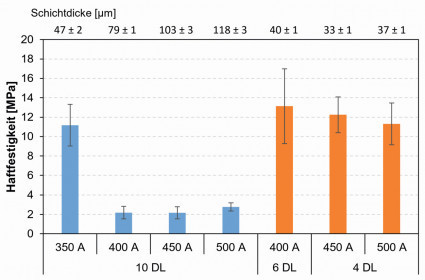

An important aspect for assessing the quality of spray coatings is the adhesive strength on the substrate material. The adhesion strength of the aluminum oxide coatings on stainless steel was determined by stamp abrasion tests. Figure 4 shows the adhesion results for selected coating parameters, indicating the resulting coating thickness. The applied coatings show adhesion values between 2 and 13 MPa. For samples with an average adhesion strength of over 10 MPa, only adhesion fractures were observed at the interface between the coating and substrate. In contrast, samples with an adhesion strength of less than 4 MPa showed a cohesive fracture in the Al2O3 coating near the substrate. Fig. 4: Determined adhesion strength using the stamp tear-off test as a function of the electrical current, for different numbers of coating passes (DL in the diagram )

Fig. 4: Determined adhesion strength using the stamp tear-off test as a function of the electrical current, for different numbers of coating passes (DL in the diagram )

It can initially be observed that the adhesive strength of the composite samples produced with 10 DL (blue bars) decreases significantly with increasing amperage, while the coating thickness increases significantly at the same time. This can be explained by the resulting residual stresses in the coating. During plasma spraying, the applied coatings are subject to continuously occurring temperature cycles due to the constant impact of particles. The rapid heating and cooling causes different expansion rates within the coating and the substrate, which leads to thermally induced stresses. These stresses can occur to a greater extent with increasing current and the associated higher temperatures. Furthermore, an increased layer thickness due to inhomogeneous cooling rates in different layer areas also causes increased mechanical stresses. This issue is discussed in detail by Araujo et al. in [11].

In a supplementary experiment (orange bars), the coating thickness for parameter sets with currents between 400 and 500 A was specifically reduced to a comparable value (approx. 40 µm) by adjusting the number of coating passes. This approach aims to minimize the temperature gradients caused by different coating thicknesses and thus reduce the residual stresses in the coating. The result is a significantly improved adhesive strength of the coatings.

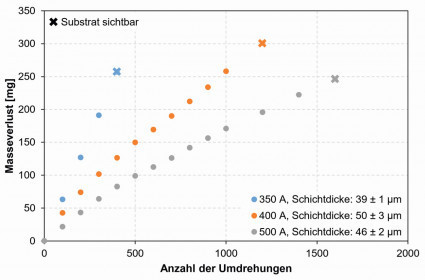

The abrasion resistance of the Al2O3 coatings was analyzed using the Taber Abraser test. Here, the abrasion resistance is defined on the basis of the mass loss after a given number of revolutions of the test specimen under the friction wheels. For the test, selected parameter sets were used that had already demonstrated high adhesive strengths in the previous tests. Furthermore, the setting of similar layer thicknesses was important for the comparability of the samples. The results of the Taber abraser test are shown in Figure 5 . The end of the test is marked with a cross. Fig. 5: Results of the Taber abraser test on the abrasion resistance of aluminum oxide coatings

Fig. 5: Results of the Taber abraser test on the abrasion resistance of aluminum oxide coatings

At a current of 350 A, the test was completed after 400 cycles. This showed a linear increase in the mass loss curve, which could indicate a uniformly distributed porosity. For currents of 400 and 500 A, the end of the test was reached after 1200 and 1600 cycles respectively. The increase in the mass loss curve is initially linear and decreases slightly from a number of revolutions of 500. This indicates that the coatings are more porous in areas close to the surface and more compact or denser at depth. Overall, it can be observed that the mass loss decreases with increasing current intensity at the same number of revolutions. These results correlate well with those of microhardness and porosity.

Summary

In this article, a method for the application of cost-effective and decorative wear protection coatings, particularly on flat, metallic components, was presented. The process also shows potential for use on slightly curved surfaces or for coating rotationally symmetrical components.

The strong influence of plasma power on the properties of cold plasma-sprayed aluminum oxide coatings was primarily analyzed. Special coating properties such as porosity, hardness, adhesive strength and abrasion resistance were investigated and could be adjusted across a broad spectrum. Depending on the set current intensity, layer thicknesses between 47 and 118 µm were achieved during plasma coating. Increasing the amperage led to a significant increase in microhardness, while at the same time porosity decreased.

The adhesion strength of the coatings was considered to be a decisive factor for industrial applicability. The adhesion values were in the range of 2 and 13 MPa. At higher currents (from 400 A) and the resulting higher coating thicknesses, a sharp drop in adhesive strength was initially observed. However, by specifically adjusting the coating thickness to values <50 µm, good adhesion to the stainless steel substrate can be achieved for all amperages considered. In addition, coatings produced at higher amperages during plasma coating exhibited improved abrasion resistance, as evidenced by lower mass loss after a certain number of abrasion cycles.

In summary, the Al2O3 coating technology offers a high bandwidth to specifically adapt the surface properties to the respective industrial requirement.

Acknowledgments

The authors would like to thank Angelika Henning, Kathrin Höse and Dr. Martina Schweder. The IGF project with the funding code 22318 BR/1 was supported by the Federal Ministry of Economics and Climate Protection.

Literature

[1] Çelik E., Şengil İ. and Avcı E., "Effects of some parameters on corrosion behavior of plasma-sprayed coatings," In: Surface and Coatings Technology, vol. 97, (1997), no. 1-3, pp. 355-360

[2] Çelik E., Demirkıran A. and Avcı E., "Effect of grit blasting of substrate on the corrosion behavior of plasma-sprayed Al2O3 coatings," In: Surface and Coatings Technology, vol. 116-119, (1999), pp. 1061-1064

[3] Çelik E., Avcı E. and Yılmaz F., "Evaluation of interface reactions in thermal barrier ceramic coatings," In: Surface and Coatings Technology, vol. 97, no. 1-3, (1997), pp. 361-365

[4] Fisher I. A., "Variables Influencing the Characteristics of Plasma-Sprayed Coatings," In: International Metallurgical Reviews, vol. 17, (1972), pp. 117-129

[5] Xu J., Körner M., Henning A., Schmidt J., Pfuch A. and Spange S., "Using cold plasma spraying to improve the bioactivity of plastic bone substitutes," In: Galvanotechnik vol. 8, (2022), pp. 1098-1101

[6] Xu J., Henning A., Pfuch A., Schmidt J., Kretzschmar B. and Grünler B., "Adhesive metallization on carbon-fiber-reinforced polymer (CFRP) by cold plasma spraying," In: Copper Symposium 2021, [Online]. Available: https://kupfer.de/wp-content/uploads/2021/11/Tagungsband-Kupfer- Symposium-2021.pdf. [Accessed on 09 02 2024].

[7] Würzl A., Xu J., Horn K., Beier O. and Pfuch. A., "Fabrication and characterization of porous cold plasma sprayed copper coatings," In: Kupfer-Symposium 2023 Vortragsband, ISBN 978-3-910411-03-6, pp. 91-96.

[8] Thirumalaikumarasamy D., Shanmugam K. and Balasubramanian V., "Influences of atmospheric plasma spraying parameters on the porosity level of alumina coating on AZ31B magnesium alloy using response surface methodology," In: Progress in Natural Science: Materials International, vol. 22, (2012), no. 5, pp. 468-479

[9] Vaßen R., Bakan E., Sebold D. and Sohn Y. J., "Correlation of Process Conditions, Porosity Levels and Crystallinity in Atmospherically Plasma Sprayed Yb2Si2O7 Environmental Barrier Coatings," In: Journal of Composites Science, Vol. 5, (2021), No. 198,

[10] Sarikaya O., "Effect of some parameters on microstructure and hardness of alumina coatings prepared by the air plasma spraying process," In: Surface and Coatings Technology, Vol. 190, (2005), No. 2-3, pp. 388-393

[11] Araujo P., Chicot D., Staia M. and Lesage J., "Residual stresses and adhesion of thermal spray coatings," In: Surface Engineering, Vol. 21, (2005), No. 1, pp.35-40,