The laser is the tool of choice for drilling a large number of similar holes next to each other. But which laser system is the fastest? And with which drilling process? The Fraunhofer ILT has been developing and testing the technology for such processes for decades.

Who needs so many holes?

The aircraft industry is under considerable pressure to further reduce fuel consumption. The principle of "Hybrid Laminar Flow Control" offers an opportunity for this: air flows around an aircraft wing with less resistance if its surface has many small holes. Fuel savings of up to 10 % are possible in this way. The situation is similar with aircraft turbines, where small holes help to dampen engine noise. A third example is filter technology. Here, metal foils with holes in the micrometer range can efficiently filter microplastics out of wastewater. These three examples show quite well that there are many holes to be drilled in very different areas. Turbine construction, paper production or plastics recycling are areas with great potential.

How can you drill with a laser?

In addition to marking, welding and cutting, drilling is also a common process. From a scientific point of view, it is a non-chipping thermal separation process. Figure 1 shows four different ways of drilling holes with a laser. The trade-off between high speed and high precision plays a decisive role in the selection. Of course, the fastest way is to "shoot" the holes through the material with single pulses. Helical drilling takes the longest and usually even requires special optics, but also offers high precision. In percussion drilling, several pulses are placed at the same point to laser a hole through the material. Trepanning is when the hole is cut out after the through-hole drilling by tracing the contour of the hole.

The precision of the hole and the smoothness of the hole walls also depend on the material and the type of laser radiation. Copper, for example, absorbs green and blue radiation much better than the usual infrared. Pulse duration and pulse energy also influence the result, which is where ultrashort pulse (USP) lasers are something very special: they apply the laser energy in an extremely short time, converting the material into a plasma almost instantaneously. As a result, USP lasers can process practically any material, they offer excellent surface quality, but also take the longest time to process.

The Fraunhofer Institute for Laser Technology (ILT) has been investigating and optimizing all of these processes for years. The result is highly productive drilling processes that can produce tens to hundreds of holes per second. The major challenge here was to maintain low tolerances of the bore diameters and a high surface quality even at a high productivity (drilling rate). The processes used here are the familiar "on-the-fly" (OTF) drilling with individual pulses and the OTF percussion drilling developed at the Fraunhofer ILT.

Example 1: OTF - single-pulse micro drilling with the laser

The most productive drilling method is OTF drilling with single pulses. It should always be noted that the speed of the process and the drill hole quality must be balanced. If the optics move too quickly over the surface, the hole becomes elongated. The quality of the drill hole can be assessed according to various parameters:

- Roundness, i.e. how far the drill hole deviates from an ideal circular shape. It is influenced by the laser and the traversing speed

- Conicity is the extent to which the diameter of the hole changes with depth

- Surface quality in the hole, which is influenced by the intensity of the laser beam

At the Fraunhofer ILT, the process was optimized so that 200 holes per second could be drilled in 1 mm thick titanium sheet. A single mode laser was used for this purpose, with which a focus diameter of just 12 µm can be achieved to produce holes with a diameter of just under 80 µm.

Fig.2: If small holes in the front part of the aircraft wing absorb the air, the formation of turbulence is reduced and less fuel is consumed. The 80 µm holes are drilled into the wing section "on the fly" at a feed rate of around 150 mm/s (Image: Fraunhofer ILT, Aachen)

Fig.2: If small holes in the front part of the aircraft wing absorb the air, the formation of turbulence is reduced and less fuel is consumed. The 80 µm holes are drilled into the wing section "on the fly" at a feed rate of around 150 mm/s (Image: Fraunhofer ILT, Aachen)

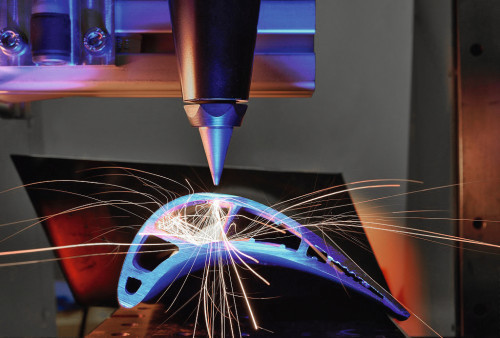

The holes were drilled "on the fly", i.e. with a constant feed rate of the optics in relation to the workpiece. With the optimized process parameters, a 2 m long 3D-moulded demonstrator of an aircraft wing was successfully machined on a 6-axis system (Fig. 2). At a speed of 200 holes per second, around 2 million holes per square meter were drilled on an area of around 2m2 in under three hours. The diameter of the holes was 80 µm. It was also important to precisely control the distance between the optics and the workpiece. OCT (optical coherence tomography) was used for this, as it is not affected by plasma or spatter and achieves a measurement accuracy of just a few micrometers.

Example 2: OTF - percussion drilling

Not all holes can be drilled with a laser pulse. Higher aspect ratios, higher requirements for hole quality or an inclination of the hole can be achieved with percussion drilling. Larger hole diameters are another application. Here, several laser pulses are shot into the same hole. It is obvious that the feed rate plays an even greater role here: The hole must be finished before the optics have moved on, otherwise the hole will be crooked, or the laser will not be able to penetrate the material at all. The duration of a hole depends on the number of laser pulses required and the repetition rate of the laser. The drilling process itself is more complex than with a single pulse. The individual laser pulses must be strong enough to drive the material further out of the hole before it is penetrated. Depending on the process parameters, the molten material can otherwise remain in the hole and solidify, shading the laser or even closing the hole.

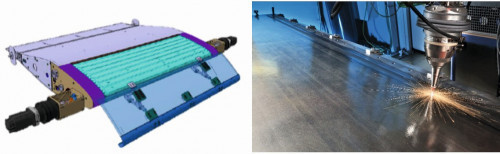

The Fraunhofer ILT has carried out extensive investigations and successfully developed an OTF process for a percussion drilling process (Fig. 3). By using a new fiber laser beam source with up to 20 kW peak pulse power and 2000 Hz repetition rate, up to 30 holes per second could be produced in 2 mm thick aluminum. Hole diameters of 500 µm were produced with a high degree of precision. The standard deviation was less than 5 % at the inlet and even less than 2.5 % at the outlet. The high peak pulse power and repetition rates of the new laser beam sources made it possible to achieve the precision of the holes and productivity.

And if that's not enough?

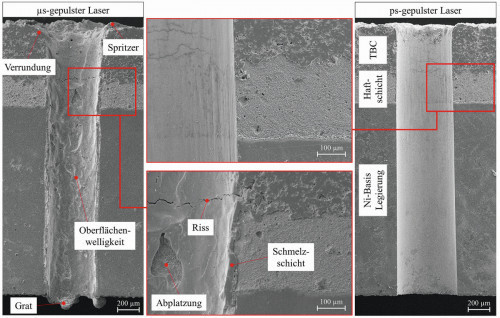

Fig. 4: Ultra-short laser pulses produce much better surfaces than short laser pulses (Image: Fraunhofer ILT, Aachen)

Fig. 4: Ultra-short laser pulses produce much better surfaces than short laser pulses (Image: Fraunhofer ILT, Aachen)

Laser and process technology is constantly evolving, and further advances in laser drilling can be expected in the coming years. In terms of beam sources, ultrashort pulse (USP) lasers with higher outputs are on the rise. They have two major advantages: On the one hand, the drill holes are more precise, defect-free, or simply smoother after USP processing, as Figure 4 shows. On the other hand, USP lasers can process practically all materials. Up to now, this has only been offset by a significantly slower processing speed. In the "Cluster of Excellence Advanced Photon Sources CAPS", experts from several Fraunhofer Institutes are currently developing beam sources with an output of well over 10 kW as well as the necessary process technology. They should also solve the current problem of the low productivity of USP lasers. Such powerful laser beam sources also enable the use of multi-beam optics. Among other things, they allow the parallel drilling of hundreds or thousands of holes.

In the SimConDrill project, filter plates for wastewater filters with millions of 10 µm holes have already been drilled in this way (Fig. 5). With such small holes, the filters can be used in public wastewater treatment plants to trap microplastics down to the sub-10 µm range. Another example is the USP laser drilling of turbine blades (Fig. 6).

Fig. 5: Filter plate for wastewater filters (Image: Fraunhofer ILT, Aachen)

Fig. 5: Filter plate for wastewater filters (Image: Fraunhofer ILT, Aachen)

The multi-beam optics can be configured in different ways: Large numbers of parallel identical partial beams can be achieved using diffractive optical elements. The distribution of the partial beams can be defined almost arbitrarily using special liquid crystal modulators. With acousto-optical modulators, individual beams can also be switched on and off.

Overall, laser drilling technology is highly dynamic. New processes are being developed and ever more powerful lasers are opening up new possibilities in terms of achievable drilling geometries and productivity. In particular, the major advances in the further development of USP beam sources will enable many new and exciting applications in laser drilling in the coming years. At the Fraunhofer ILT, the know-how is being developed from basic research to industrial application and system development.