Optical filter layers on glass are manufactured using state-of-the-art vacuum processes. One disadvantage of these methods is the high level of technical equipment required and the associated costs. A promising method for atmospheric pressure-based functionalization is the sol-gel technique.

In this dip coating process, which is mainly used in industry, flat substrates are coated from both sides depending on the process. This is a disadvantage for the product group mentioned, as a one-sided coating and different types of coating are required on the individual surfaces. A promising approach for efficient one-sided optical functionalization is the application of a coating solution using a slot die. Optically homogeneous layers could be deposited on untreated glass and advantageously also on plastic surfaces using this technique as part of a development project. Through a combination with other atmospheric technologies, it has been possible to significantly increase the adhesion of coatings on polymer-based surfaces.

Fig. 2: Left) Plasma pre-treatment of PMMA sheet material with Tigres T-Jet; right) Pyrosil pre-treatment

Optical coating as the final production step

In its product portfolio, the Mainz-based company Glas-Plus Beschichtungs GmbH & Co. KG offers, among other things, glass coated with interference layers that are transparent for a certain wavelength range of light but reflect the rest (so-called dichroic filters). The color effect of these filter layers depends on the angle of incidence of the incident light and the viewing angle of the observer. Such optical filter layers on glass, e.g. beam splitters (Fig. 1) or reflective color filters, are applied using state-of-the-art vacuum processes (sputtering / evaporation). The sol-gel process is an atmospheric pressure-based alternative. The coating solution (sol) can be applied using various methods. Due to the inadequate coating quality when spraying the sol, the dip coating process is preferred for the production of optically demanding coatings. Depending on the process, the substrate is coated on both sides. For a one-sided coating, the back of the substrate must be masked with protective lacquer or foil or, after annealing (T > 450 °C), the layers must be removed from the back using an etching process.

Fig. 3: Slot die coating of PMMA sheet material with Titan-Sol

Fig. 4: Principle of the stamp tear-off test (left) and bonded sample (right) Both methods are time-consuming and produce a significantly higher reject rate. In addition, the necessary decoating process is technically difficult to implement on large surfaces. Alternatively, two glass substrates can be bonded together on the rear sides. Due to the repeated bonding processes required for multi-layer systems (one bonding process per layer), this process is also not very economically viable. Furthermore, the current market in the field of optical coatings is increasingly moving in the direction of final format coating for both full and partial surface functionalization. Ever smaller optical components, such as filters for optics and even curved surfaces, are only coated and installed after cutting, edge and surface finishing. However, dip coating only allows the coating of raw formats, which are only cut to size and edge-finished after the coating has been applied. Numerous optical functionalizations also require partially applied multi-layer designs, even on curved geometries. Strongly curved or spherical components cannot be coated using the dipping process either, as the drawing speed on the substrate surface changes significantly locally due to the curvature during the dipping process. This leads to variations in coating thickness and the associated color and functional variations in the coating design. All in all, it can be seen that the changing market can be served less and less by means of dipping processes. Slot die technology offers a promising option for the high-quality, large-area application of functional sol-gel layers in the nanometer range. In the following, the potential of this technology for efficient one-sided optical functionalization will be examined in more detail.

Fig. 4: Principle of the stamp tear-off test (left) and bonded sample (right) Both methods are time-consuming and produce a significantly higher reject rate. In addition, the necessary decoating process is technically difficult to implement on large surfaces. Alternatively, two glass substrates can be bonded together on the rear sides. Due to the repeated bonding processes required for multi-layer systems (one bonding process per layer), this process is also not very economically viable. Furthermore, the current market in the field of optical coatings is increasingly moving in the direction of final format coating for both full and partial surface functionalization. Ever smaller optical components, such as filters for optics and even curved surfaces, are only coated and installed after cutting, edge and surface finishing. However, dip coating only allows the coating of raw formats, which are only cut to size and edge-finished after the coating has been applied. Numerous optical functionalizations also require partially applied multi-layer designs, even on curved geometries. Strongly curved or spherical components cannot be coated using the dipping process either, as the drawing speed on the substrate surface changes significantly locally due to the curvature during the dipping process. This leads to variations in coating thickness and the associated color and functional variations in the coating design. All in all, it can be seen that the changing market can be served less and less by means of dipping processes. Slot die technology offers a promising option for the high-quality, large-area application of functional sol-gel layers in the nanometer range. In the following, the potential of this technology for efficient one-sided optical functionalization will be examined in more detail.

Material and methods

Fig. 5: Glass breakage after stamp breakageThesubstrate materials used were 3 mm thick planar samples of borofloat glass from Schott Glas and polymethyl methacrylate (PMMA) from Rocholl GmbH. Depending on the application, the substrate size was 10 x 15 cm or 30 x 40 cm. Before slot die coating, the glass samples were cleaned with ethanol in an ultrasonic bath, rinsed with distilled water and dried at room temperature. In the case of the PMMA samples, the factory-applied protective film was removed in preparation for the sol application.

Fig. 5: Glass breakage after stamp breakageThesubstrate materials used were 3 mm thick planar samples of borofloat glass from Schott Glas and polymethyl methacrylate (PMMA) from Rocholl GmbH. Depending on the application, the substrate size was 10 x 15 cm or 30 x 40 cm. Before slot die coating, the glass samples were cleaned with ethanol in an ultrasonic bath, rinsed with distilled water and dried at room temperature. In the case of the PMMA samples, the factory-applied protective film was removed in preparation for the sol application.

With the aim of improving adhesion, various tests were carried out to pre-treat the PMMA surfaces using selected atmospheric pressure-based plasma and flame treatment processes. In addition to a T-Jet plasma system from Tigres, a Pyrosil system was used for flame treatment (Fig. 2). During the treatment, the PMMA surfaces were scanned in a meandering pattern with the plasma nozzle; the power of the plasma torch was constant at 360 W. With the aid of an x-y traversing table, the substrate below the outlet opening of the plasma nozzle was also moved at speeds of between 25 mm/s and 200 mm/s.

Two in-house titanium sols and a silicon sol from Glas-Plus Beschichtungs GmbH und Co KG were used as coating solutions. The sol was applied using a slot nozzle from Mitsubishi. Figure 3 shows an example of the coating process of a PMMA surface with one of the titanium sols. Following the wet chemical layer deposition, the glass samples were annealed at 480 °C for 30 minutes and the PMMA samples at 80 °C overnight.

This was followed by examinations of the coating adhesion and an evaluation of the spectral properties. The transmission/reflection behavior of the samples was determined using a Tec5 diode spectrometer. To evaluate the homogeneity of the coating along the 30 cm x 40 cm samples, measurements were carried out at selected points on the sample. To assess the coating adhesion, stamp tear tests (see Fig. 4) were carried out using an Inspect table universal testing machine from Hegewald & Peschke Meß- und Prüftechnik GmbH. First, metal stamps are glued to the coated surfaces using a suitable adhesive. This is then separated from the sample in the tensile test and the tensile strength is determined. The layers were either separated from the substrate together with the metal stamp (adhesive fracture) or destroyed in themselves (cohesive fracture). If the applied tensile forces were greater than the strength of the substrate material, the material broke (Fig. 5).

Results and discussion

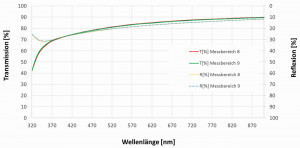

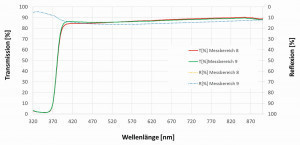

Optically homogeneous layers could be deposited on both the glass and PMMA samples using slot die application. Figures 6 and 7 show exemplary transmission/reflection measurement curves on glass and PMMA respectively.

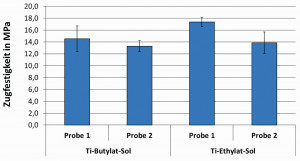

The evaluation of the tensile tests on borofloat glass confirms very good coating adhesion due to high tensile strength and glass breakage during stamp breakage (Fig. 8).

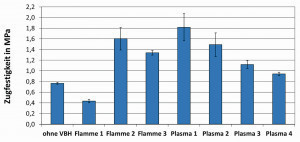

As expected, the adhesion of the sol-gel layers to PMMA was lower (Fig. 9). However, a clear influence of the pre-treatment process on the adhesion is recognizable. In particular, the gas/air ratio of the flame-treated samples and the travel speed of the plasma torch had a significant influence on the adhesion values. The highest tensile strengths were achieved with atmospheric plasma pretreatment. Compared to PMMA without pre-treatment, the adhesive strength was more than doubled.

Conclusion and outlook:

In the course of our work, we succeeded in applying selected sol-gel layers to both glass and PMMA surfaces on one side, quickly and economically, with the required optical quality. Both in terms of coating adhesion and transmission/reflection properties, a quality comparable to that of dip-coated products was achieved. With the help of an atmospheric pressure-based pre-treatment process, it was also possible to significantly increase the adhesion of the coating to the flat PMMA surfaces.

In a further step, the coating technology developed is to be used to apply a layer or layer system to a suitable carrier material (transfer film), with which a layer transfer to both planar and three-dimensional surfaces is possible. This should enable the market for optical layer filters to be served efficiently in the future. Initial tests have been successfully carried out.

In the case of inversely transferred layers (application of the transfer film with the sol-gel-coated side on the glass surface), both excellent adhesion and very good abrasion resistance of the layers on glass were observed. However, the optical layer quality achieved after the transfer has not yet fully met the high requirements. This should be the aim of further investigations.