As part of the "CoaxHybrid" research project of the German Welding Society (DVS), the Fraunhofer Institute for Laser Technology ILT has combined gas metal arc welding (GMAW) and laser cladding with a ring beam to create a completely new process. With the COLLAR Hybrid process, the welding speed can be increased and the deposition rate in metallic 3D printing can be increased.

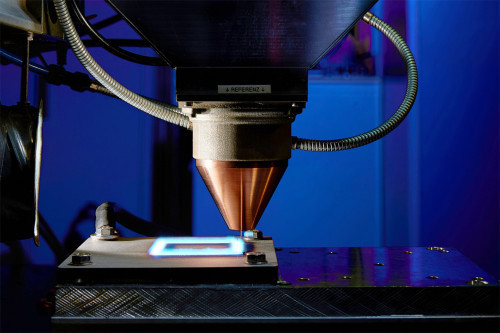

The new COLLAR Hybrid Additive Manufacturing process is based on a combination of arc and laser deposition. (© Fraunhofer ILT, Aachen / Volker Lannert.)

The new COLLAR Hybrid Additive Manufacturing process is based on a combination of arc and laser deposition. (© Fraunhofer ILT, Aachen / Volker Lannert.)

The new process is a combination of two additive processes with wire-shaped filler material, wire arc additive manufacturing (WAAM) and wire laser material deposition (WLMD). In the hybrid process, the arc between the end of the wire and the substrate is enclosed by the laser beam in a conical shape, like a collar. The idea behind this combination is that the arc cannot break out of this collar and is forcibly guided. With this combination, deposition rates can be increased by up to 150 percent, meaning that the new direction-independent 3D printing process is also suitable for large components. The process is also suitable for non-linear joining and has further advantages compared to the individual processes.