The fem's expertise ranges from materials development, electrochemistry and galvanic surface finishing, light metal surface technology, paint coatings and plasma-assisted coating processes to material and surface analysis. Activities in the field of plasma surface technology are carried out by the Plasma Surface Technology - Materials Physics (POT-MPh) department. This research spectrum is discussed in this article.

The fem Forschungsinstitut Edelmetalle + Metallchemie celebrated its 100th anniversary in September 2022. It has been the world's only independent institute for precious metals research since 1922. However, this important area of research now only accounts for a small proportion of fem's research activities. The research objectives are now generally in the fields of materials science and surface technology. Here, forward-looking solutions are developed for industry and in particular for SMEs.

The fem's new R&D focal points are battery systems and hydrogen technology, digitalized process technology, intelligent surfaces and raw material and resource efficiency. The institute is currently expanding its premises to include a 4,500 square meter innovation laboratory K15 (see Fig. 1). There, the fem will intensify practice-oriented R&D work in materials science and surface technology for the important future fields of energy technology, resource efficiency and digitalized process technology and expand technology transfer to SMEs and industry. The project is funded by the European Regional Development Fund (ERDF) as part of the Union's response to the Covid-19 pandemic.

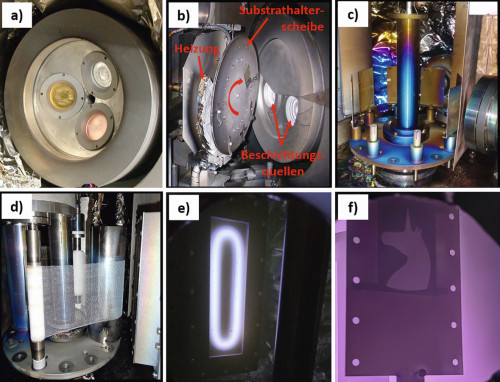

Fig. 2: PVD coatings on a) stationary substrates with up to 3 coating sources (confocal arrangement of the targets); b) rotating substrates (uniaxial rotation of the substrate holder disk in front of up to 3 coating sources); c) moving substrates (1-fold, 2-fold rotation); d) roll-to-roll transport of the strip material as well as e) magnetron plasma on rectangular cathode and f) etching plasma on substrate before decorative coating

Fig. 2: PVD coatings on a) stationary substrates with up to 3 coating sources (confocal arrangement of the targets); b) rotating substrates (uniaxial rotation of the substrate holder disk in front of up to 3 coating sources); c) moving substrates (1-fold, 2-fold rotation); d) roll-to-roll transport of the strip material as well as e) magnetron plasma on rectangular cathode and f) etching plasma on substrate before decorative coating

The fem is divided into six subject-specific departments, but the article only deals with plasma surface technology. The so-called POT-MPh department was founded at fem in 1989, has four vacuum coating systems and deals with plasma-assisted deposition, plasma surface modifications and the characterization of both untreated and coated or modified surfaces. The properties of material or component surfaces can be adapted to the respective physical and chemical stresses by means of plasma modifications and/or coatings without affecting the volume properties of the components. The substrate materials used are diverse and include steels, hard metals, metals, polymers, ceramics, glass and textiles. These can be coated and/or surface-modified stationary, with single or double rotation or roll-to-roll (R2R) (see examples in Fig. 2). The areas of application range from wear and corrosion protection to decorative applications and medical (e.g. biocompatible coatings) and energy technology (fuel cells, batteries).

Physical vapor deposition (PVD)

Three of the four vacuum coating systems in the fem's POT-MPh department are equipped for PVD deposition using magnetron sputtering. Various DC and MF voltage supplies and two HiPIMS pulsers are available for operating the sputter cathodes. In addition to standard coatings, such as TiN, TiAlN, CrN etc., specific coating developments with regard to chemical composition or coating design (multilayer coatings, nanocomposite coatings) are also carried out for research projects, but also in direct cooperation with industry. Some of the possible process variants in the field of PVD are described below.

Development of new alloys by PVD deposition

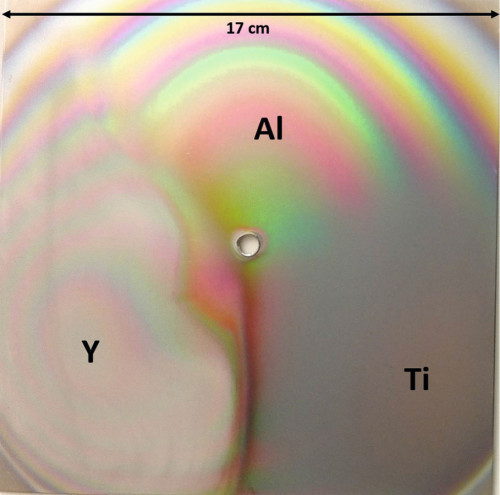

With a fixed substrate and the use of two or three sputtering cathodes, material screenings can be carried out (combinatorial material synthesis). This process is currently being used as part of an IGF project ("RefMagS", No. 21989 N) with two sputtering cathodes. The aim of the project is to develop corrosion-protective and wear-resistant coatings. One sputtering cathode with a magnesium target and a second sputtering cathode with a refractory metal target (RM = titanium, vanadium, chromium, etc.) are operated simultaneously in an Ar/N2 atmosphere. Opposite the two sputtering cathodes are a series of fixed individual substrates. The chemical composition of the layer varies on the row of substrates from almost pure Mg nitride to a mixture of Mg-RM nitride and almost pure RM nitride. A subsequent salt spray test shows the Mg content at which the corrosion resistance of the coated steel substrates improves. The magnesium in the coating acts like a sacrificial anode, among other things.

For the deposition of binary or ternary metal alloys (or metal compounds such as nitrides, carbides or oxides) with a specific chemical composition, the substrates can be mounted on a rotating substrate holder (see Fig. 2b) so that a series of model substrates can be coated under the same conditions. The advantage of this method is that each individual sputtering source can be controlled separately and thus almost any binary or ternary alloy composition can be produced as layers on the substrates very easily using pure metal targets (no alloy targets). Depending on the rotation speed of the substrate holder, fully intermixed layers (very fast rotation) through to multilayer layers (very slow rotation) can be deposited.

In two other research projects, three sputtering cathodes were used for the development of decorative coatings (BMFT project no. 13N5834 (Fig. 3 a) - for further details see [1], EU project "Colored Gold" no. COOP-CT-2006-032497). In the aforementioned EU project, blue and purple gold alloys were deposited using a gold target in combination with two other metallic targets [2]. Another option for producing decorative coatings is based on a two-stage process that produces homogeneous, transparent oxide layers with very brilliant interference colors on 3D components. First, a niobium metal layer is deposited using PVD. In a second step, the coated component is then anodically oxidized on the surface (example: Nb-coated vase in Fig. 3 b).

Semi-industrial coatings

One of the PVD systems (POTatO) is prepared for semi-industrial coatings. Components can be coated in small batches with 1 to 2-fold rotation (see Fig. 2 c, 2 e, 2 f and 4 a). Two different sizes of coating sources are available: circular 75 mm sputtering cathodes and rectangular sputtering cathodes with a height of 20 cm (see Fig. 2 e); more detailed information on this can be found in [1].

Roll-to-roll (R2R) coatings

Another coating variant is the roll-to-roll (R2R) coating of films or textiles, for example. For this purpose, an R2R unit was set up and integrated into the system as part of a ZIM project ("MetTex", no. KF2342815AJ4) (see Fig. 2 d). This now allows the sputter coating of strip material with a width of up to 200 mm.

Chemical vapor deposition (PACVD)

In a fourth vacuum system, which is currently equipped with two plasma beam sources (inductive and capacitive), PACVD depositions and surface activations and etchings are carried out. The capacitive plasma beam source is a system component provided by HS-Group GmbH. Both sources use gases (Ar, N2, O2, C2H2) as well as liquids with high vapor pressure (e.g. TMS) as precursors. The capacitive plasma jet source has been successfully used for the deposition of nitrogen-doped hydrocarbon layers (IGF projects "BlackBip" and "HiRaCarbon"). The coating process developed for this is a promising method for depositing electrically conductive layers to protect against corrosion of metallic bipolar plates in PEM fuel cells [3]. Furthermore, silicon-containing layers and hard diamond-like carbon layers (DLC) can be produced.

Thermochemical heat treatment

In addition to coating deposition, the plasma jet sources on the PACVD system were also used for thermochemical heat treatment. In a ZIM project, the plasma nitriding of various types of steel - including stainless steel - was investigated [4]. It was found that short-term nitriding of just a few hours in particular led to higher nitrogen concentrations in the steel compared to conventional plasma nitriding. Depending on the gas atmosphere used, carburizing, carbonitriding, oxidizing or oxynitriding is also possible. A voltage supply for plasma immersion ion implantation (PIII) has also recently become available to the fem (a detailed description of PIII can be found in [5]). This allows high-voltage pulses of up to -25 kV to be applied to the component, causing the plasma to form directly around the component. Layer deposition is also possible with this voltage supply.

Plasma characterization

The POT-MPh department has access to methods such as plasma monitoring (see Fig. 4 b), mass spectrometry, optical emission spectrometry, Langmuir probe measurement and oscillating quartz systems for basic investigations of the plasmas used in surface technology.

Layer and material characterization

A variety of methods are available at the fem to characterize materials, coatings or modified surfaces. Table 1 below lists a selection of methods that are commonly used in the field of plasma surface technology.

|

Material and coating characterization |

Process |

|

Surface topography |

Confocal microscopy; tactile profile and roughness measurement |

|

Microstructure |

FE-SEM, FIB-SEM, crystal structure and microtexture analysis (EBSD), X-ray diffraction, grazing incidence (GIXRD), |

|

Coating composition |

EDX/WDX, GDOS, ICP-OES, ICP-MS, AAS, FTIR |

|

Electrical properties |

Electrical conductivity |

|

Coating thickness |

Calotest, profilometry, X-ray fluorescence, X-ray reflectometry |

|

Adhesive strength |

Rockwell indentation test, adhesive tensile strength (ASTM C 633) |

|

Hardness |

Instrumented indentation test / nano hardness |

|

Color, gloss, transmission |

Simultaneous spectrometer, gloss measurement, transmission measurements |

|

Contact angle |

Water contact angle (hydrophilic, hydrophobic) |

|

Friction, wear |

Pin-on-disc tribometer and oscillating vibration wear |

|

corrosion |

Electrochemical measurements, spray mist (NSS, ESS, CASS) |

|

Thermal properties |

Differential thermal analysis (DTA), calorimetry (DSC), |

Concluding remarks and outlook

The fem's POT-MPh department is equipped with a wide range of possibilities to react flexibly to new research topics or industrial inquiries. In addition to the further development of established coatings based on PVD and PACVD processes, exotic new coating compositions can also be deposited and specific coating structures designed. This puts the department in an excellent position to support industry in the development of new coating materials, to advise on the optimization of industrial coating processes and to provide the necessary clarification in the event of damage using the measurement technology available at the research institute or to offer and carry out in-process investigations as a service. The department is constantly involved in collaborations with SMEs and large companies as part of industrial and/or publicly funded projects.

Extensive analysis and testing facilities are available in the department and throughout the institute for the investigation of layer depositions and surface modifications. If individual processes are not available, we cooperate with national and international partners.

The POT-MPh department is also successfully active in the field of thermochemical heat treatment using plasma jet sources. The possibilities available for this were also recently expanded with the acquisition of a high-voltage generator for plasma immersion ion implantation. The plan for the near future is to enter the field of thermal CVD, more specifically the Atomic Layer Deposition (ALD) process. As part of an ERDF project (H2-Aspen / Hy-FIVE lighthouse project), an ALD chamber is to be integrated into a new cluster system. The ALD module should also be able to be operated separately from the cluster system and will also offer the possibility of plasma-assisted ALD (PE-ALD).

Acknowledgments

We would like to thank the project sponsors BMFT, BMBF, DFG, EU and BMWi/AiF for their long-term financial support.

Literature

[1]M. Fenker: Diverse research and development in the field of plasma surface technology - material physics, Galvanotechnik, No. 12 (2016) 2548-2558

[2]U.E. Klotz: Metallurgy and processing of colored gold intermetallics - Part II: Properties and surface processing, Gold Bulletin, Vol. 43, No. 1 (2010) 4-10

[3]M. Fenker; J. Julin; K. Petrikowski; A. Richter: Physical and electrical properties of nitrogen-doped hydrogenated amorphous carbon films, Vacuum 162 (2019) 8-14

[4]M. Fenker; K. Petrikowski; G. Preiß: Plasma nitriding of austenitic stainless steel using a plasma jet source, Jahrbuch Oberflächentechnik, Vol. 69 (2013) 91-98

[5]W. Ensinger: Modification of mechanical and chemical surface properties of metals by plasma immersion ion implantation, Surface and Coatings Technology 100-101 (1998) 341-352