Projections assume that 11.3 TWh of electricity from renewable energies will need to be temporarily stored in Germany in 2050 - around a tenth of the wind energy produced in 2021. So far, there has been no breakthrough in storage development. The Swiss company Swiss Clean Battery is now aiming to achieve this with the series production of a new solid-state battery in Switzerland. The new battery has pioneering properties and could disrupt the market for storage technologies.

It is a sunny day in Zurich at the beginning of April when a small group of journalists gather at the Hotel Schweizerhof in the center of the Swiss financial hub for a press event organized by Swiss Clean Battery AG (SCB). The announcement of the construction of a gigafactory for solid-state batteries - the world's first - had aroused their curiosity; after all, the term "gigafactory" almost instinctively brings to mind Elon Musk, who has just opened his Tesla gigafactory in Grünheide near Berlin just 900 kilometers to the north-east. However, despite all the euphoria about electromobility and its important role in the decarbonization of mobility, theCO2-intensive production of the vehicles is a constant source of irritation. Battery production, which also uses elements such as lithium and cobalt, is particularly important in this respect. The extraction of lithium is difficult and costly, while cobalt comes mainly from the Congo, where it is mined under precarious conditions. Other shortcomings of today's batteries include the risk of fire and explosion, rapid discharge at sub-zero temperatures and a relatively short service life.

Battery technology without flaws?

A substance that is produced when batteries age and was first produced artificially just a few years ago. This so-called "stable conductive salt" prevents the ageing process of rechargeable batteries when dissolved in the electrolyte

A substance that is produced when batteries age and was first produced artificially just a few years ago. This so-called "stable conductive salt" prevents the ageing process of rechargeable batteries when dissolved in the electrolyte

The new battery from Switzerland apparently solves all the weaknesses of current battery production at the same time: it is durable, non-flammable and resistant to deep discharge and also has a 50% smallerCO2 footprint than lithium-ion-based storage technologies. Its development can be traced back to the company HPB (High Performance Battery), which was mentioned by Wirtschaftswoche in the Founders section in 2019. A developer named Günther, who spent 30 years researching battery chemistry at the Fraunhofer Institute, is said to have discovered a substance that ensures that the electrolyte in which the charged particles move within the battery becomes solid. HPB could produce this substance itself and "give batteries an eternal life", Wirtschaftswoche reported three years ago.

Then as now, Dr. Thomas Lützenrath was part of HPB. He is now also Chief Operation Officer (COO) of SCB. The company, based in Frauenfeld near Zurich, was founded in February and paid HPB 100,000 euros for the license for the solid-state battery. The aim now is to turn the development into a genuine innovation and a problem solver for energy storage. In Zurich, Dr. Lützenrath presented the technology and the business concept for series production together with CEO Roland Jung and CFO Peter Koch.

Multimillion investment required

Dr. Thomas Lützenrath, Roland Jung and Peter Koch (from left to right) at the media conference in Zurich with a test battery. Series production of the solid-state battery is set to start in Switzerland in just 18 monthsTheGigafactory in Switzerland is set to produce the new solid-state battery in around 18 months. The initial aim is to scale up to a capacity of 1.2 GWh. Ultimately, the target is 7.6 GWh. Turnover will increase from CHF 318 million to just over CHF 2 billion. Production will take place on an area of 20,000 square meters with a projected workforce of more than 1,000 employees as soon as the far-reaching construction plans have been realized. The first stage of expansion will require an investment of 300 million Swiss francs (296 million euros), as CFO Peter Koch calculates. The same amount is to be invested again for the operational start-up. Pension funds and investment funds are the backers, and SCB also intends to raise between 60 and 100 million Swiss francs when it goes public on the Swiss stock exchange in October.

Dr. Thomas Lützenrath, Roland Jung and Peter Koch (from left to right) at the media conference in Zurich with a test battery. Series production of the solid-state battery is set to start in Switzerland in just 18 monthsTheGigafactory in Switzerland is set to produce the new solid-state battery in around 18 months. The initial aim is to scale up to a capacity of 1.2 GWh. Ultimately, the target is 7.6 GWh. Turnover will increase from CHF 318 million to just over CHF 2 billion. Production will take place on an area of 20,000 square meters with a projected workforce of more than 1,000 employees as soon as the far-reaching construction plans have been realized. The first stage of expansion will require an investment of 300 million Swiss francs (296 million euros), as CFO Peter Koch calculates. The same amount is to be invested again for the operational start-up. Pension funds and investment funds are the backers, and SCB also intends to raise between 60 and 100 million Swiss francs when it goes public on the Swiss stock exchange in October.

The solid-state battery is regarded as the successor technology to conventional lithium-ion batteries. Intensive research is being carried out worldwide. One example is the solid-state battery specialist QuantumSpace, with which Volkswagen is collaborating and which is working with similar financial resources to those envisaged by the SCB management.

If the expectations for the new battery technology prove to be true, this will be an important milestone in helping the energy transition to succeed. It could also reduce dependence on fossil fuels, which is currently under particular criticism due to the war in Ukraine, faster than expected.

100,000 charging cycles possible

While conventional lithium-ion batteries age because a top layer grows on their anodes through charging and discharging, causing the internal resistance to increase and the performance to decrease, the new SCB solid-state battery only develops a thin top layer during the first charge, which does not get any thicker from then on. Internal resistance and performance remain constant, according to SCB. And for 100,000 charging cycles instead of just 3000 as with lithium-ion batteries - a 33-fold increase in service life. Technically, this should be possible by saturating the electrolyte solution in the battery with the newly developed substance, which ultimately also solidifies the electrolyte. During the process, the electrolyte is cooled down to temperatures close to absolute zero (approx. -270 °C) to avoid humidity and then reheated to around 20 °C.

Home and industrial storage units from SCB. Energy security increases with the help of a powerful storage system. In addition, renewable electricity can be used flexibly. Load management in manufacturing companies should no longer be necessary

Home and industrial storage units from SCB. Energy security increases with the help of a powerful storage system. In addition, renewable electricity can be used flexibly. Load management in manufacturing companies should no longer be necessary

The battery is incombustible because hardly any lithium is used. Lithium phosphate is only used in the cathode area. This also makes recycling easier. The battery is thermally recycled, i.e. incinerated, leaving only the metals.

Metals and metal processing also characterize the series production of the batteries in the Gigafactory: "The housing is pressed and coated. Finally, it is filled with liquid electrolyte," says Dr. Lützenrath. The solid conductor between the anode and cathode consists mainly of graphite, as the manager reveals. The chemistry will come from Brenntag in Basel, among others, and the graphite from a mine in Turkey to ensure regionality.

Support from renowned research partners

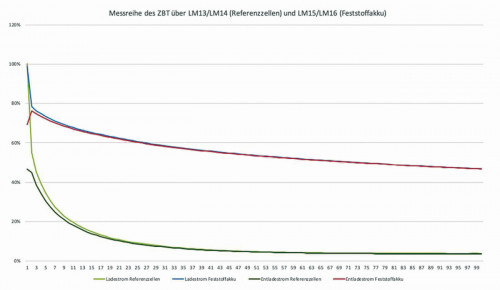

A series of measurements by the ZBT at the University of Duisburg-Essen, in which 100 charging cycles of conventional and SCB batteries were compared. Charging and discharging resulted in higher initial capacities and lower capacity decreases

A series of measurements by the ZBT at the University of Duisburg-Essen, in which 100 charging cycles of conventional and SCB batteries were compared. Charging and discharging resulted in higher initial capacities and lower capacity decreases

"Our test batteries and functional cells show that the process works," says Dr. Lützenrath confidently. His company relies on two partners in particular to validate the results: the Swiss Federal Laboratories for Materials Science and Technology (empa) and the Center for Fuel Cell Technology (ZBT) at the University of Duisburg-Essen. Results from empa support Lützenrath's conviction, as the material properties of the solid ion conductor first developed there in 2019 have changed only slightly over the course of a year. Reason enough for CEO Roland Jung to place the development of the SCB solid-state battery in a historical context. This is a moment that people will tell their grandchildren about one day, he assured the assembled journalists.

A benefit for society, industry and the climate

If the breakthrough comes, there will initially be storage systems for stationary applications from next year, i.e. industrial storage systems "to cap electricity peaks" as well as storage systems for renewable energies. In principle, however, solid-state batteries can also be used for charging infrastructure, in data centers, for mobility on land, at sea and in the air, as well as in the field of consumer electronics, for which further investment would be required.

Even if only a small number of the announcements materialize, the solid-state battery represents a significant leap forward in battery technology. In addition to the many advantages of the new battery, there are also the manufacturing costs, which are said to be a tenth cheaper than those of conventional lithium-ion batteries thanks to the use of standard raw materials. This means that the possible uses of clean energy in society and industry can be increasingly expanded and become more flexible, while the climate benefits from further reductions inCO2 emissions.