AGRU-FRANK GmbH relies on an energy-efficient container cooling solution from Reisner Cooling Solutions GmbH for its production expansion.

The requirements in plastics extrusion are constantly increasing - efficient and resource-saving production is becoming increasingly important. Refrigeration technology is a decisive factor here, as a modern cooling solution can significantly reduce energy costs and cutCO2 emissions. The example of plastic pipe manufacturer Agru-Frank GmbH shows that an investment pays for itself in a very short time. Due to its expansion, the company invested in a container cooling solution from Reisner Cooling Solutions GmbH, a technotrans group company. This reduced costs and created more space in the production halls.

Agru-Frank GmbH, based in Wölfersheim, is one of eleven companies in the Frank Group. Agru-Frank manufactures polyethylene pipes for drinking water and gas supply as well as for waste water disposal and industrial requirements. The company also manufactures special and multilayer pipes. In order to meet the growing demand, Agru-Frank has invested in several new machines and systems.

The production of pressure pipes, fittings and geothermal probes consists of various process steps. For pipe extrusion, small plastic granules are melted and shaped into pipes using a tool. The plastic, which is heated to around 220 degrees Celsius, is then cooled again to retain its shape. With a view to expanding production capacity, however, there was no longer enough cooling capacity available, especially in the summer months. The high temperatures caused the cooling water temperature to fluctuate greatly. As a result, the need for efficient cooling technology increased as part of the production expansion.

When selecting the right solution concept for its own cooling system, Agru-Frank had several requirements. Firstly, the cooling solution had to be able to regulate the cooling water temperature satisfactorily even in summer by providing more power. Energy efficiency and heat recovery in particular played an important role in the purchasing decision. Secondly, the system needed to be appropriately dimensioned in order to have sufficient reserve capacity in the event of further positive company development and production expansion. In addition, as little space as possible was to be taken up in the company's own production hall.

The Reisner concept convinced Agru-Frank in all respects: "During the planning phase, Reisner covered several of our requirements at once and ensured optimal conditions with the concept of a customized refrigeration system with special VARIO energy-saving technology, a sliding condensation pressure control and heat recovery," emphasizes Stribrny. Set up in a container, Reisner adapted the solution to the customer's needs using two KWR-S 400-17/KS refrigeration systems, each with a cooling capacity of 400 kW and two condensers with energy-saving EC fans. The service also ensured lasting customer satisfaction: "We felt very well advised. We also received competent and reliable support throughout the entire project," says Stribrny.

Maximum cooling capacity and unique energy-saving technology

Efficiency in particular played a role in the decision, as a lot of energy is consumed during plastic extrusion: "As an energy-intensive company, we see it as our duty to use resources responsibly," says Stribrny. For this reason, the pipe manufacturer has been certified in accordance with the energy management standard DIN EN ISO 50.001 for several years. This requires a continuous increase in efficiency in production as well as the identification of potential savings and compliance with certainCO2 emission values. Whenever a new refrigeration system is purchased, the company therefore pays attention to low resource consumption. "Increasing efficiency will continue to play an important role in the coming years. New drives for the production machines, more effective cooling of the pipes and a holistic approach in the context of the circular economy will be the drivers in the plastic pipe sector over the next few years," explains Stribrny. Maximum cooling capacity in harmony with energy efficiency and sustainability were therefore important premises for the company. Reisner therefore integrated a unique energy-saving technology that significantly reduces power consumption and operating costs.

The tailor-made refrigeration system consists of two separate refrigeration machines, each with a maximum cooling capacity of 400 kW, so that a total of 800 kW is available. The refrigerant used, R513A, has excellent thermodynamic properties and a significantly lower GWP (Global Warming Potential) value than conventional refrigerants. Another advantage is the use of so-called Vario technology. Thanks to a special valve technology and special electronic control, the Reisner cooling solution adapts the condensation temperature to the outside temperature. This saves up to 477,490 kWh per year. The Reisner project team explains: "The electronic control system measures the outside or condensation temperature. The colder it is outside, the more the condensation temperature is reduced, which lowers the electrical compressor power consumption." An additional dry cooler also takes over the entire load of the two systems in winter operation and supports them during the transition period. This results in a total annual saving of around 900,000 kWh or 480,000 kilograms ofCO2. Last but not least, AGRU-FRANK uses the heat recovery from a chiller to heat a production process in summer when the winter relief, i.e. free cooling, is not active. To make the best possible use of the waste heat, Reisner developed a concept with which heating water can be heated using a heat exchanger in the refrigerant circuit.

Space-saving container as machine room

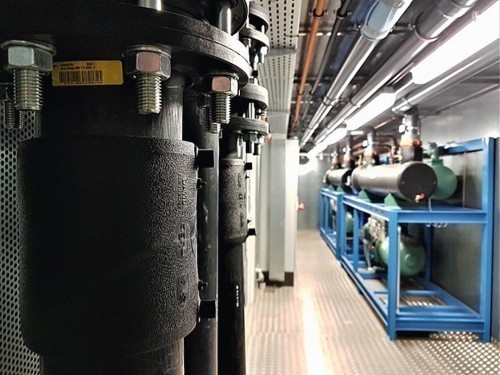

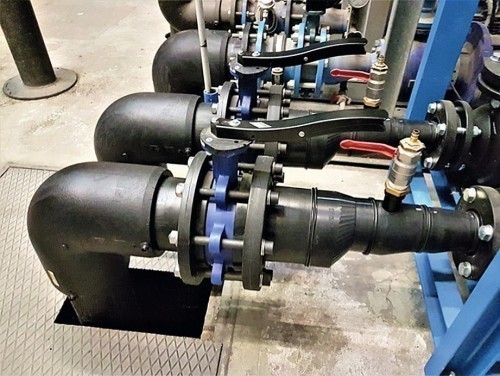

Due to the structural conditions, the two refrigeration systems would no longer have fitted into the existing AGRU-FRANK production halls. As part of the project planning, the Reisner team therefore developed a twelve meter long and two and a half meter wide container as a machine room. This is equipped with the two refrigeration systems, a control cabinet with Siemens PLC, supply and exhaust air grilles, gas warning system, exhaust air fans, electric heating and lighting. Reisner was also responsible for the complete electrical cabling inside the container and the cabling of the outdoor units on the container roof during installation and assembly. "The container solution is perfectly tailored to our needs. Relocating the refrigeration technology outside the building freed up valuable space in our production halls," says Stribrny. Reisner also installed modern PE100-RC piping from the FRANK Group for the connections from the container to the tank, which, unlike PVC, are permanently welded.

Thanks to the closed design, the refrigeration system can be easily repositioned and used at a different location. Stribrny explains: "The Reisner container solution is very well thought out. We were particularly impressed by the idea of placing the entire unit in front of the hall. This allowed us to create additional space should production increase further." As AGRU-FRANK opted for a large container, additional expansion of the system is possible quickly and without great effort thanks to the reserve space already provided. This means that the container can be extended with minimal effort and a higher cooling capacity can be achieved quickly. The Reisner project team sums up: "Thanks to flexible expansion options, our systems are ready for the future today."

Water filter and piping made of PE 100-RC with fittings from the FRANK Group.

Water filter and piping made of PE 100-RC with fittings from the FRANK Group.

The entire project took just under six months. Commissioning finally took place in summer 2020. Stribrny is visibly satisfied with the result: "You could see the improvements on the very first day after commissioning. There have been no more temperature fluctuations in our production water since then." With the modernization, AGRU-FRANK and Reisner have laid the foundation for further cooperation. The service and accessibility are also particularly emphasized by the customer - further projects are therefore to follow. Reisner's next project is to replace the water pumps, for example. Here too, an active control system with energy-efficient and frequency-controlled supply pumps will significantly reduce the power consumption of the pumps. AGRU-FRANK is also currently building a new production hall: "We will continue to grow and, of course, we always need cooling," says Stribrny.

All images: AGRU-FRANK GmbH

INFO

Factsheet: Refrigeration technology 2020 for AGRU-FRANK GmbH

Project partner:

- AGRU-FRANK GmbH

- Reisner Cooling Solutions GmbH

Demand:

- Additional cooling capacity of 2 x 400 kW

- Maintain cooling water temperature in summer

- Energy efficiency and heat recovery

- Reserve capacities

- More space in own production halls

Solution:

- Two Reisner chillers with 400 kW cooling capacity each

- refrigerant R513A with GWP 631

- two chiller condensers with EC fans

- Container as machine room

- Control and regulation technology

Energy-saving features:

- Winter relief via dry cooler

- Chiller with Reisner Vario

- EC fans

Period:

January 2020/supply phase until July 2020/final acceptance