Special processes in industry, including the application of electroplated layers, must be described so precisely that everyone involved in the process knows what needs to be done at all times. All process activities must be fully documented and traceable at all times. The CQI standard of the North American automotive industry provides assistance in this regard.

Introduction

The publisher of the CQI (Continuous Quality Improvement) standards is the AIAG (Automotive Industry Action Group), an association of the North American automotive industry based in Detroit / Michigan / USA, which was founded in 1982 by Chrysler, Ford and GM. The AIAG is a globally recognized organization in which OEMs and suppliers jointly clarify questions of standards and continuously develop them further in the so-called process-specific working groups. In 2007, AIAG required all direct T1 automotive suppliers that develop and supply parts and components to the "big three" (Chrysler, Ford and GM) for so-called "special processes" to confirm that they meet the CQI standards applied in each case. Furthermore, the T1 suppliers also require their sub-suppliers to provide evidence that they have carried out CQI self-assessments.

The aim of the CQI standard is to create a global quality standard for products throughout the entire supply chain. A special process is defined as a process in which the process result cannot be fully verified without destructive testing. The process characteristics only become apparent once the product has been put into operation. Special processes are, for example, galvanic coatings, heat treatments, surface coatings, welding, soldering, casting, etc.

The aim of these process management standards is to reduce the error rate, process variation and losses through a continuous improvement process and to achieve higher plant availability. The standards require the process owner to describe the entire special process so precisely that misconduct by all persons involved in the process can be ruled out at any time and in any situation. The described process management system must be demonstrably trained by all those involved in the process, including an effectiveness test.

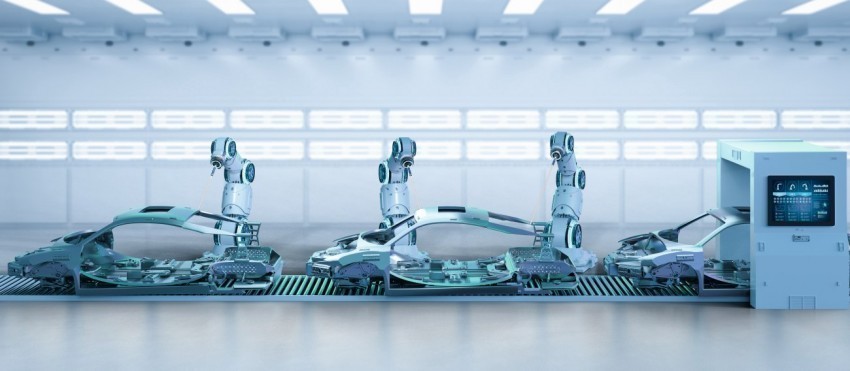

Although modern production facilities run without human intervention in many areas, the qualification of employees is crucial

Although modern production facilities run without human intervention in many areas, the qualification of employees is crucial

The process management system is regulated in the quality management manual, process descriptions, process, work and test instructions, maintenance plans, etc., among other things. Reproducibility of product quality and complete order traceability must be guaranteed. Employee qualification is therefore a key feature and a basic prerequisite for successful implementation of the standards. The qualifications of man and machine, as well as their maintenance, must be verifiably documented.

These standards, combined with an internationally recognized quality management system and applicable customer-specific requirements, define the basic requirements for the process management system. It is essential that these standards are integrated into all areas of management, value creation and support.

Management processes:

Corporate planning, resource management, controlling, management system evaluation

Value creation processes:

Marketing and sales, project management & development, work preparation, production, logistics and shipping

Support processes:

Purchasing, personnel management, financial management, maintenance and servicing, IT, quality management, environmental management

For example, a company's sales department should be aware of the costs involved in implementing the process standard. Costs that have not been calculated correctly in advance when submitting an offer can usually no longer be claimed from the customer at a later date. When placing orders, the purchasing department must pay attention to the requirements of the process standards. For example, control and regulation units, which are necessary for process control and monitoring, must fulfill various requirements. When purchasing a new system or modifying an existing one, it is advisable to draw up a specification sheet and refer to the relevant process standard at the same time. Maintenance and servicing must also align their service with the standard. Similar examples are reflected throughout the company.

Successful implementation of these standards in the company is not possible without the backing of top management. This must provide the necessary resources for man and machine.

In principle, the process owner should not see these standards as a necessary evil for placing an order, but as an effective tool for implementing, monitoring and continuously improving his process in the best possible way. If these standards are applied correctly, the necessary investments in people and machines will pay off in the long term. After introducing and applying these standards, process owners will confirm that they have never before examined, described, regulated, monitored and documented their processes so intensively.

The following CQI special processes are currently standardized:

- CQI-9 Evaluation of heat treatment systems: 4th version - Edition 06/2020

- CQI-11 Evaluation of galvanic surface treatments: 3rd version - edition 11/2019

- CQI-12 Evaluation of surface coating systems: 3rd version - Edition 07/2020

- CQI-15 Evaluation of welding processes: 2nd version - Edition 10/2019

- CQI-17 Evaluation of brazing processes: 1st version - Edition 03/2010

- CQI-23 Evaluation of plastic molding processes: 1st version - Edition 03/2014

- CQI-27 Evaluation of casting processes: 2nd version - Edition 03/2018

The above standards can only be purchased from the AIAG at www.aiag.org

With the exception of the CQI-9 standard, all standards are only available in English. Based on this situation, it is recommended that the standard is translated into the respective company language. This is the only way to reach all process-relevant employees in a company and receive the necessary feedback from the know-how carriers regarding a precise description of the process management system.

In IATF 16949:2016, the application of the CQI standard is only recommended. The specific request for demonstrable compliance with the CQI standard is solely customer-specific. It is a self-assessment, which is the sole responsibility of the process owner. An official certificate is not issued by an independent body. A company certification according to IATF 16949:2016 is not mandatory, but more and more efforts must be made to close the gap to DIN EN ISO 9000 ff.

In order to set up or review the process management system, the AIAG provides the process owner with audit questionnaires for the applicable process standard, which must be checked for conformity. Parallel to the audit questionnaire, process-specific process tables and customer-specific requirements must be taken into account. The functionality of the process management system in production is then specifically checked using a historical production order with the help of a job audit questionnaire.

Example:

Audit question catalog - table of contents CQI-11(galvanic coatings)

- Management responsibility and quality planning (employee qualification, sampling, FMEA, PLP, recipes, instructions, document management system, data analysis, CIP, complaint management system, control of defective products, etc.).

- Responsibility for the material handling work area (handling, cleanliness, identification, traceability, labeling, order management system, storage areas, etc.)

- Pyrometry (thermocouples, instrumentation, system accuracy test (SAT), temperature uniformity test (TUS))

- Job audit (contents from section 1-3 and the process tables).

Process tables

- Zinc / zinc alloy coating

- Mechanical coating

- Decorative coating of metal substrates

- Decorative coating of plastic substrates

- Electropolishing and flash chrome

- Hard chrome plating

- Electroless nickel

- Hydrogen annealing

- Inspection and calibration of process control and testing equipment.

In the process tables, the coating line or the individual process steps / basins are specifically addressed and requirements such as e.g: Temperature, time, current, voltage, pH values, concentrations, kinetics, flow rates, metallic impurities, water quality, process & test equipment, pyrometric requirements, etc.

The number of deviations identified during the audit are documented on a cover sheet and made available to the customer as proof of implementation. Deviations that directly endanger the product are subject to immediate corrective action. In this case, production must be stopped. Production can only be resumed after successful shutdown. However, the customer cannot interpret the audit result meaningfully with the cover sheet alone. It would make sense for the customer to receive the cover sheet together with the action plan resulting from the audit. This gives the customer the opportunity to weight and track the deviations.

The CQI audit must be carried out at least once a year and in special circumstances by qualified personnel. At least 2 days should be scheduled to carry out a meaningful CQI audit. This is the only way to achieve the required audit focus. It is always better for the process owner to know what he can and cannot do before the customer reveals the actual potential.

AIAG defines qualified personnel (auditors) as having the following qualifications:

- The auditor is an experienced internal auditor for QM systems, e.g. in accordance with ISO 9001, IATF 16949

- Specialized training and/or a practical activity with at least 5 years of professional experience

- Knowledge of the application of the quality tools and Q methods of the automotive industry as well as the "Automotive Core Tools" (APQP, SPC, MSA, PPAP, FMEA)

- Alternatively, auditing can also take place in a team of auditors, in which the above-mentioned qualifications must be represented, whereby the lead auditor must fulfill point 1.

The action plan resulting from the audit is of great importance. This lists the deviations found, describes the causes and defines the necessary corrective actions. Nonconformities must be eliminated within 90 days, including an effectiveness test.

There are company-specific situations in which the process owner is unable to implement conformity with the CQI standard or uses other technical solutions. In this case, the process owner can only close the deviation if the customer agrees to the existing conditions. This is possible because the CQI requirements are complementary to the customer and product standards.

Conclusion:

The primary objective of CQI process management systems is to describe the special process so precisely that all persons involved in the process know what needs to be done. Professional and documented sensitization of those involved in the process, including an effectiveness check, is absolutely essential. All process activities must be fully documented and traceable at all times.

The customer requires nothing more from his supplier than that he reproduces the process and product quality according to the initial sample approval until he requests a different procedure. If the supplier is unable to fully demonstrate compliance with the CQI requirements or the initial sampling conditions, there is a risk of financial compensation being demanded in the event of any complaints / recalls.

With the CQI standard, the audit quality depends primarily on the qualification of the internal auditor. If the auditor does not approach the audit with the required accuracy, an audit result is determined that does not necessarily correspond to the actual circumstances. Due to a possible operational blindness, the use of a neutral auditor / specialist is recommended, who offers optimal audit conditions and at the same time can successfully apply the standard as a CIP tool.

Creating a process management system is one thing, but maintaining the system over the long term requires discipline from everyone involved!