Hybrid lightweight construction is of great interest in the modern automotive industry. The combination of steel and aluminum components to reduce weight plays a particularly important role here. Consequently, research into suitable production technologies for joining these materials is absolutely essential, especially in the field of car body construction. In addition to processes such as welding and soldering, die casting is an innovative method for the production of aluminum/steel hybrid components.

As the cooling rates in die casting are many times higher than in most other joining processes, it is much more difficult to produce materially bonded joints. For this reason, the material bond is to be influenced by coating the sheets with different layer systems. The main objective of the current study is to understand the bonding mechanisms for aluminum/steel sheet joints in the die casting process and to investigate the factors influencing them.

1 Introduction

In order to control the bonding mode at the interface between molten aluminum and steel and to analyze its influence on the formation of brittle intermetallic AlFe phases and on a possible gap formation between the molten Al and the steel sheet, coatings of Cu-, Ni- and Al-based alloys were first applied to the steel sheet by thermal spraying and brazing. Of particular interest is the analysis of these coatings with regard to the microstructural development of the Al-cast/coating/steel substrate contact zone. In addition to metallographic investigations using light and scanning electron microscopy, the thermal behavior of the coatings was analyzed in differential calorimetric measurements. In addition, the joint quality was analyzed as a function of the temperature distribution on the steel surface during die casting.

Steel and aluminum have been the most important materials in the automotive industry for decades. In particular, the hybrid structures made of both metals to combine the good mechanical properties of steel with the low density of aluminum should lead to weight reduction and thus to a reduction in fuel consumption andCO2 emissions in the transport sector. However, joining aluminum and steel is a challenging task due to the very different thermophysical and material bonding properties of the two materials and the formation of brittle intermetallic phases at the interface. In addition to welding and brazing, die casting is an alternative technique for joining dissimilar metals. Hybrid die casting of aluminum onto a steel insert has been the focus of research at RWTH Aachen University in recent years [1, 2]. Despite initial successes, further improvement of the bonding properties is required, as the problem of brittle intermetallic phases and gap formation at the aluminum/steel interface has not been completely solved.

There are three types of bond that can occur in a material composite: Material bonding, force bonding and form bonding. Due to the extreme cooling rates after die casting and the insufficient wetting of steel by aluminum, it is challenging to realize a material bond at the interface. The aim of the current study is to investigate different coatings for the steel insert and their influence on the microstructure formation, growth kinetics and chemical composition of the joining zone. The greatest challenge is the application of coatings with reliable adhesion to the steel substrate that enable a material bond with the aluminum casting during die casting. In the die casting process, the steel substrate is heated to a temperature of T = 500-520 °C, while

the temperature of the molten aluminum is approx. T = 700 °C [1]. Therefore, two Al-based alloys with a low solidus temperature were selected as the coating material in order to enable partial melting of the coating in the die casting process and thus achieve a material bond with the casting alloy. Furthermore, Ni5Al coatings applied by means of high-speed flame spraying were investigated, which should enable a good positive bond in the die casting process due to the infiltration of the porosity by the melt. In addition, variants with Cu coatings were also investigated to avoid a metallurgical reaction between aluminum and steel and the resulting formation of intermetallic phases. These coatings were produced by means of brazing. An overview of the application techniques and coating concepts is given in Figure 1 .

2 Test setup and description

In the current study, cold-rolled deep-drawing steel DC04 was selected as the substrate material, which is used in car body construction, among other things. The composition of the steel, the coating materials and the Al cast alloy AlSiMn9 is shown in Table 1.

| Si | Mn | Mg | C | S | P | Cu | Al | Fe | Zn | Ni | |

| DC04 | 0,40 | 0,08 | 0,03 | 0,03 | bal. | ||||||

| AA4145 | 10,00 | 4,00 | bal. | ||||||||

| AA7075 | 0,4 | 0,3 | 2,5 | 1,6 | bal. | 5,5 | |||||

| Ni5AL | 5,0 | bal. | |||||||||

| AlSi9Mn | 9,0 | 0,4 | 0,08 | 0,03 | bal. | 0,15 |

2.1 Spray tests

The untreated steel was used in the cold-rolled state and after sandblasting. Aluminum oxide with a grain size of F80 (149 µm-210 µm) was used as the abrasive. AA4145 powder with a grain size distribution of -45 +15 µm and AA7075 powder with a grain size distribution of -63 +20 µm were supplied by TLS Technik GmbH (Bitterfeld, Germany). The Kinetiks 8000 cold gas spraying system from Oerlikon Metco (Pfäffikon, Switzerland) was used to deposit the Al-based coatings with nitrogen as the process and carrier gas.

The high velocity oxy-fuel (HVOF) K2 system from GTV Verschleißschutz GmbH (Luckenbach, Germany) was used to apply the Ni5Al coating. The spraying parameters for both Al-based alloys and for the Ni5Al coating are shown in Table 2.

| Parameters | AA4145 (CGS) / AA7075 (CGS) | Ni5Al (HVOF) |

|

Gas temperature [°C] |

490 | |

|

Process gas flow, N2 [m3/h] |

60 | |

|

Carrier gas flow, N2 [m3/h] |

3,0 | |

|

O2 flow [slpm], (HVOF) |

870 | |

|

Kerosene (Exxsol D60) [l/h], HVOF |

20 (λ = 1,26) |

|

|

Spray distance [mm] |

25 | 300 |

|

Robot speed [mm/s] |

200 | 1.000 |

2.2 Brazing

The brazing process for applying the Cu foil with a thickness of d = 100 µm was carried out in a PVA MOV 553 vacuum furnace. The samples were heated to a temperature of T = 1,100 °C in a high vacuum at a heating rate of approximately Ṫ = 20 K/min. The holding time at brazing temperature was t = 10 min.

2.3 Casting tests

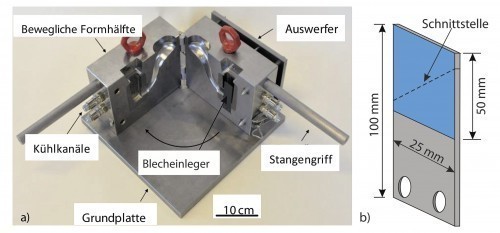

In order to investigate the wetting behavior of the coated samples, they were recast in an oil-cooled composite mold with the casting alloy AlSi9Mn (Trimal 37). The mold is shown in Figure 2 . The mold was preheated to a temperature of T = 170 ± 4 °C before the test. After placing the sample in a special device, it was overmolded with the AlSi9Mn melt at a temperature ofTs = 720 ± 5 °C. After solidification, the casting was removed from the mold and cooled in air.

Fig. 2: a) Oil-cooled composite mold for the recasting tests, b) Geometry of the coated steel insert

Fig. 2: a) Oil-cooled composite mold for the recasting tests, b) Geometry of the coated steel insert

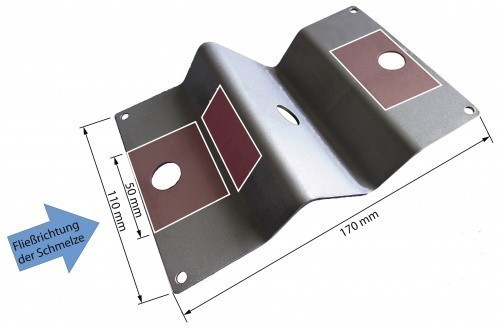

The die casting tests on the samples with selected coatings were carried out on the Frech DAK 450 Vacural die casting cell from Oskar Frech GmbH + Co KG (Schorndorf, Germany). A sheet metal insert with a ribbed structure was used to improve the rigidity of the overmolded component. The geometry of the sheet metal insert for the die casting tests is shown in Figure 3 .

Fig. 3: Steel sheet insert for the die casting tests with the three marked positions of the coatings

Fig. 3: Steel sheet insert for the die casting tests with the three marked positions of the coatings

Due to the complex structure of the sheet metal insert, the full-surface coating of the steel using cold gas spraying was only possible to a limited extent. Therefore, three specific areas were defined on the sheet surface,

which represent different process conditions during die casting and which were selectively coated (Fig. 3). The velocity of the melt is particularly high in the inflow area of the die casting tool. Accordingly, the highest pressure of up to p = 40 bar can be expected at this point. For this reason, this area of the steel insert poses particularly high challenges for the coating in terms of adhesive strength. Behind the first rib of the insert, the flow slows down considerably, so that the velocity drops by a factor of approx. 5. According to Lao's investigations, the maximum temperatures in the middle area of the steel insert are approx. T = 500 °C [1].

2.4 Analysis

In order to characterize the coating, the cold gas-sprayed samples were examined metallographically with regard to their microstructure. The diffusion processes at the Al casting/coating/steel interface after die casting and pressure die casting were analyzed using energy dispersive X-ray spectroscopy (EDX) on the Zeiss Leo 1530 scanning electron microscope with the Bruker Quantax 200 EDX detector. The thermal behavior of the coatings was investigated using differential scanning calorimetry (DSC) on a SETSYS Evolution 16/18 thermal analysis system from Setaram Instrumentation (Caluire, France). Both spray materials in their original form as powders and coated samples were heated from room temperature to T = 650 °C at a heating rate of Ṫ = 10 K/min.

3 Results and discussion

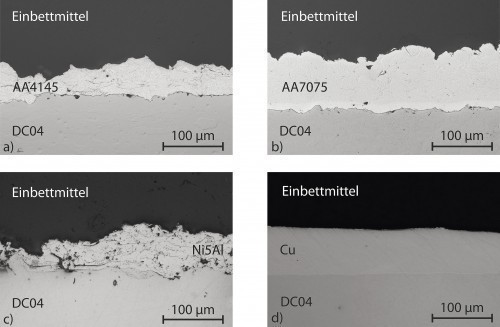

For the AA4145 alloy, it was difficult to achieve sufficient bonding on the untreated substrate by cold gas spraying. After sandblasting the steel surface with aluminum oxide F80, a coating with a thickness of approximately d = 60 µm was deposited after four passes (Fig. 4a). The porosity of the AA4145 coating was approximately p = 1 %. The spray tests showed that the AA7075 alloy can be deposited on the steel substrate by cold spraying without prior surface treatment.

Figure 4b shows the cross-section of the AA7075 coating. The starting material exhibits good ductility, resulting in a strong bond between the particles. The coatings of AA7075 have a porosity of about p = 0.5 %. The thickness of the coating was about d = 150 µm.

Fig. 4: Light microscope images of the a) cold gas sprayed AA4145 coating, b) cold gas sprayed AA7075 coating, c) HVOF sprayed Ni5Al coating, d) brazed Cu coating

Fig. 4: Light microscope images of the a) cold gas sprayed AA4145 coating, b) cold gas sprayed AA7075 coating, c) HVOF sprayed Ni5Al coating, d) brazed Cu coating

The nickel-based alloy Ni5Al can be processed well using HVOF (Fig. 4c). The coating has a compact structure with a low porosity of approx. p = 2 %. Compared to the cold gas-sprayed coatings, the oxide content is noticeably higher in the case of the Ni5Al HVOF coating. The average coating thickness of the Ni5Al coating was d = 90 µm after seven passes. Defects such as cracks or blasting material inclusions can rarely be seen in the cross-section. In contrast to the thermally sprayed coatings, the soldered-on Cu layer has a material bond with the steel substrate. It also has a homogeneous microstructure and a smooth surface (Fig. 4d). The thickness of the Cu coating was approx. d = 100 µm.

3.1 DSC analysis

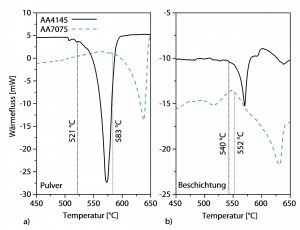

Fig. 5: DSC analysis of the AA4145 and AA7075 alloys in the initial powder state and after application to the steel substrateIn order todetermine the influence of thermal processes on the phase formation at the interface between the steel and the coating, the Al-based coatings were analyzed using differential scanning calorimetry measurements. The interest in both materials lies in the fact that their two-phase solid/liquid range overlaps with the process temperatures of die casting. With these alloys, partial melting of the coating during the die casting process is to be expected, which should support the formation of a metallurgical bond between the melt and the coating. In a Magmasoft simulation by Lao et al. the temperature at the surface of the sheet metal insert was calculated for the entire die casting process. This showed that the maximum temperature at the surface reaches values in the range T = 500-520 °C [1]. The two Al-based alloys were examined in their initial form as powder and after application to the steel. The results of this analysis can be seen in Figure 5 . A pronounced endothermic peak can be observed for all samples, which can be attributed to the melting of the alloys. The theoretical solidus temperature of the AA4145 alloy isTSol = 520 °C. Compared to pure powder, the melting temperature of the coating is slightly shifted to higher temperatures.

Fig. 5: DSC analysis of the AA4145 and AA7075 alloys in the initial powder state and after application to the steel substrateIn order todetermine the influence of thermal processes on the phase formation at the interface between the steel and the coating, the Al-based coatings were analyzed using differential scanning calorimetry measurements. The interest in both materials lies in the fact that their two-phase solid/liquid range overlaps with the process temperatures of die casting. With these alloys, partial melting of the coating during the die casting process is to be expected, which should support the formation of a metallurgical bond between the melt and the coating. In a Magmasoft simulation by Lao et al. the temperature at the surface of the sheet metal insert was calculated for the entire die casting process. This showed that the maximum temperature at the surface reaches values in the range T = 500-520 °C [1]. The two Al-based alloys were examined in their initial form as powder and after application to the steel. The results of this analysis can be seen in Figure 5 . A pronounced endothermic peak can be observed for all samples, which can be attributed to the melting of the alloys. The theoretical solidus temperature of the AA4145 alloy isTSol = 520 °C. Compared to pure powder, the melting temperature of the coating is slightly shifted to higher temperatures.

The AA7075 alloy has a higher melting temperature ofTSol = 583 °C in the initial powder state compared to the AA4145 alloy, although the theoretical melting range of this alloy is between T = 477 °C-635 °C [3]. In the study by Atkinson et al. it was shown that the melting of the AA7075 alloy begins with the dissolution of the MgZn2 phase [4]. Due to the presumably low proportion of this phase, the melting range of AA7075 is only detected at higher temperatures. Interestingly, in the case of the AA7075 alloy, the melting peak is shifted to lower temperatures in the as-sprayed state. Rokni et al. showed that the microstructure of AA7075 powders undergoes a strong change during cold spraying, including the size and distribution of precipitates [5, 6]. This may be a possible reason for the shift in the melting range due to thermal spraying. For both coatings, the melting range is just above the expected temperatures at the sheet surface in the die casting process, which were determined in Lao's simulation. The temperature difference is in the range of approx. ΔT = 20 °C, which means that partial melting of the coating cannot be ruled out.

3.2 Casting tests in an oil-cooled mold

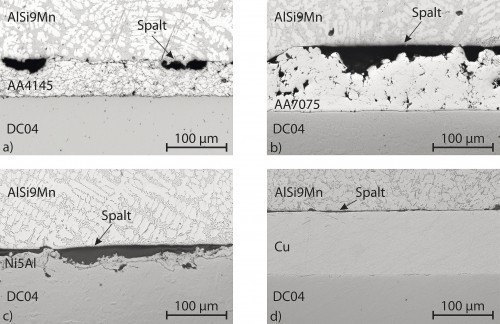

The cross-sections of the samples recast with AlSi9Mn melt are shown in Figure 6 . The light microscopic images showed that in all samples there is a gap between the solidified Al melt and the coated samples of a few micrometers to a few millimeters. The formation of this gap is due to the poor wetting of the coatings by the melt and their volume contraction during solidification. In some places it can be seen that the liquid melt partially reproduces the surface profile of the coating, as in Figure 6c for the Ni5Al coating. No infiltration of the porosity by the melt could be metallographically verified in the case of the Ni5Al coating. Only in the case of the AA4145 coating was there a partial material bond between the melt and the coating on approx. 15 % of the total contact surface (Fig. 6a). There was a thin gap of a few micrometers between the cast Al alloy and the Cu coating (Fig. 6d).

Fig. 6: Cross-sections of recast samples with a) CGS-AA415 coating, b) CGS-AA7075 coating, c) HVOF-Ni5Al coating, d) brazed-on Cu coating

Fig. 6: Cross-sections of recast samples with a) CGS-AA415 coating, b) CGS-AA7075 coating, c) HVOF-Ni5Al coating, d) brazed-on Cu coating

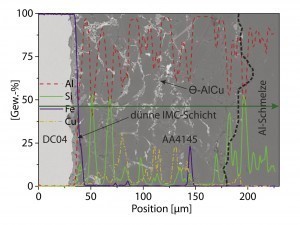

Fig. 7: SEM/EDX analysis of a recast sample coated with AA4145 alloyFig. 7 shows the results of an SEM/EDX measurement at a point with a material bond between the AA4145 coating and the molten Al. In the microstructure of the coating, bright phases can be seen at the particle boundaries. As can be seen from the EDX measurement, these phases have a copper content of up to 40% by weight with aluminum as the main component. The formation of an intermetallic θ-AlCu phase can be inferred from the aluminum-copper phase diagram. According to the EDX analysis, a thin reaction zone of AlFeSi phase can be identified at the interface between steel and AA4145 alloy (Fig. 7). The composition of the reaction zone corresponds to the composition of α- and β-AlFeSi, namely Al12Fe5Siand Al5FeSi. The intermetallic phase fringe has a structure and composition comparable to those from immersion tests of steel sheets in an Al melt in the work of Fragner et al. and Nazari et al [7, 8].

Fig. 7: SEM/EDX analysis of a recast sample coated with AA4145 alloyFig. 7 shows the results of an SEM/EDX measurement at a point with a material bond between the AA4145 coating and the molten Al. In the microstructure of the coating, bright phases can be seen at the particle boundaries. As can be seen from the EDX measurement, these phases have a copper content of up to 40% by weight with aluminum as the main component. The formation of an intermetallic θ-AlCu phase can be inferred from the aluminum-copper phase diagram. According to the EDX analysis, a thin reaction zone of AlFeSi phase can be identified at the interface between steel and AA4145 alloy (Fig. 7). The composition of the reaction zone corresponds to the composition of α- and β-AlFeSi, namely Al12Fe5Siand Al5FeSi. The intermetallic phase fringe has a structure and composition comparable to those from immersion tests of steel sheets in an Al melt in the work of Fragner et al. and Nazari et al [7, 8].

3.3 Die casting tests

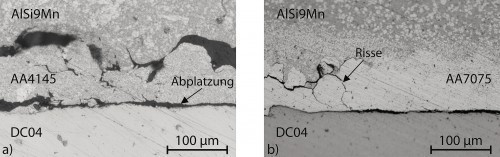

Taking into account the results from the casting tests in an oil-cooled mold, two Al-based coatings were selected for the first die casting tests. The light microscope images in Figure 8a show that bonding between the AA4145 coating and the Al melt was only observed in small areas. The cross-section shows that the coating was probably pulled off the substrate and damaged due to the contraction during solidification of the melt. Such damage can also be found in some areas of the AA7075 coating. Figure 8b shows that some cracks in the coating run along the coating/melt interface.

Fig. 8: Cross-sections of die-cast samples coated with a) AA4145 and b) AA7075 alloy

Fig. 8: Cross-sections of die-cast samples coated with a) AA4145 and b) AA7075 alloy

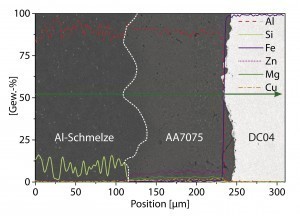

Fig. 9: SEM/EDX analysis of a die-cast sample coated with AA7075Thematerial bond between the Al melt and AA7075 coating could be partially established. In the sprue area, where the melt has the highest velocity, the coatings were severely damaged or partially removed. A good bond between the molten Al and the coating was achieved in the middle area of the sheet insert, where theoretically the highest temperature was reached.

Fig. 9: SEM/EDX analysis of a die-cast sample coated with AA7075Thematerial bond between the Al melt and AA7075 coating could be partially established. In the sprue area, where the melt has the highest velocity, the coatings were severely damaged or partially removed. A good bond between the molten Al and the coating was achieved in the middle area of the sheet insert, where theoretically the highest temperature was reached.

An SEM/EDX measurement was carried out to describe the interaction between the melt/coating/steel interface. Figure 9 shows the results of this analysis in the form of a line scan.

The interface between the molten Al and the coating can be recognized in particular by the progression of the silicon and zinc content. A flat transition in the zinc indicates the diffusion of this alloying element into the melt and therefore a good material bond between the coating and the melt. Neither interdiffusion at the interface between steel and coating nor the formation of intermetallic AlFe phases was observed.

Summary

Four different coatings on a steel insert for hybrid die casting of aluminum were investigated. The preliminary tests on an oil-cooled die showed that the HVOF-sprayed Ni5Al coating is insufficiently wetted for a positive connection with the Al melt. With the soldered-on Cu coating, a significantly smaller gap was observed between the molten Al and the coating, but no interlocking bond could be produced. In the case of the two Al-based coatings AA4145 and AA7075, a material bond to the Al melt could only be partially established. Based on these results, the behavior of the two Al-based alloys was investigated in the die casting tests. It was shown that the quality of the hybrid bond strongly depends on the position on the sheet insert. This is due to the fact that the pouring speed of the melt and the temperature on the surface of the steel insert are inhomogeneous. Severe damage to the coating was observed in the pouring area, which can be attributed to the high speed of the melt in this area. A good material bond was achieved in the middle area of the steel inlay. The quality of the bond between the melt and the coating was significantly better in the case of the AA7075 alloy, although the results of the DSC analysis at the process temperatures suggest that the AA4145 coating melted somewhat more strongly, which should result in a better bond with the Al melt.

Furthermore, the hybrid structures made of aluminum and steel are to be analyzed in tensile tests and randomly in fatigue tests. The aim here is to correlate the interaction of the material partners and, in this respect, to gain a comprehensive understanding of the formation and structure of the bonding zone between the sheet and the casting. Furthermore, the corrosion behavior of the die-cast Al/steel hybrid structures will also be investigated.

Acknowledgments

The current study is funded by the German Research Foundation (DFG) as part of the project no. BO 1979/39-1 "Treatment of steel sheets for the die casting of low-gap and low-distortion aluminum casting/steel-

sheet metal hybrids".

The authors are grateful for this funding. Special thanks go to our project partners at the Foundry Institute (GI) and the Institute for Image Forming (IBF) at RWTH Aachen University.

Literature

[1] Lao, B.: Die-cast metal hybrid structures for the lightweight construction process, materials and microstructure of metal hybrids,

University Library of the Rheinisch-Westfälische Technische Hochschule Aachen, Aachen, 2013

[2] Oberschelp, C.: Hybrid lightweight structures for car body construction - casting material-oriented application investigations

for die casting, Foundry Institute of the RWTH, Aachen, 2012

[3] Ostermann, F.: Application Technology Aluminum, 3rd ed. Springer Berlin Heidelberg, Berlin, Heidelberg, 2014

[4] Atkinson, H.V.; Burke, K.; Vaneetveld, G.: Recrystallization in the semi-solid state in 7075 aluminium alloy,

Materials Science and Engineering: A 490/1-2, 2008, 266-276

[5] Rokni, M.R.; Widener, C.A.; Crawford, G.A.; West, M.K.: An investigation into microstructure and mechanical properties of

cold sprayed 7075 Al deposition, Materials Science and Engineering: A 625, 2015, 19-27

[6] Rokni, M.R.; Widener, C.A.; Crawford, G.A.: Microstructural evolution of 7075 Al gas atomized powder and high-pressure

cold sprayed deposition, Surface and Coatings Technology 251, 2014, 254-263

[7] Fragner, W.; Papis, K.; Wosik, J.; Uggowitzer, P.J.: Herausforderungen und Lösungsmöglichkeiten bei der Herstellung von

Verbundgussteilen, lecture text, 5th Ranshofener Leichtmetalltage 2008, LKR-Verlag, edited by U. Noster,

F. Riemelmoser and P. J. Uggowitzer, Ranshofen, 2008, 75-85

[8] Nazari, K.A., Shabestari, S.G.: Effect of micro alloying elements on the interfacial reactions between molten aluminum

alloy and tool steel, Journal of Alloys and Compounds 478/1-2, 2009, 523-530