Cradle of electroplating in Germany - VEB Galvanotechnik Leipzig (GTL) 1985 to 1989: The year 1989 was significantly influenced by the political upheavals in the European Eastern Bloc countries, which were caused by the growing protest of the population. With the first democratic parliamentary elections in Poland, the dismantling of Hungary's border fortifications with Austria in May and Czechoslovakia's border fortifications in December and the fall of the Berlin Wall on November 9, 1989, the Iron Curtain was opened. The individual events of this year will not be discussed, as they are certainly still fresh in our memories.

Economic development of GTL from 1986 to 1989

It is certainly interesting for the outsider to know how a company in the GDR was organized using the example of GTL with approx. 1500 employees. The structure of a company was subject to certain changes over the decades. Directorates were merged and separated again, new ones were created or renamed according to the requirements or ideas of the plant managers or directors.

The directorates listed below were generally subdivided into main departments, divisions and groups, which were also subject to change. At the end of the 1980s, GTL had the following structure:

In addition to the director of operations with his office, there was a director for cadres and education (P), for workers' supply (V), for sales and foreign trade (H), for economics (Ö), for science and technology (W), for rationalization and basic fund technology (T), for material procurement (M), for production(F), for chemical production (C) as well as a chief accountant (B) and a state director of TKO (Q). Most of these directors had offices with secretaries and research assistants.

In addition to these directorates, there was also the SED works council and the FDGB works union leadership, which played an active role in shaping the company. Above all, the party in the form of the party secretary exerted more or less influence on the directors and the development of the company, depending on their qualifications and loyalty to the party line.

Plan and plan fulfillment

In the years 1986 to 1989, the GTL collective achieved the best plan fulfillment in years. The plan was fulfilled or exceeded, with the following results being achieved (in million DM):

| 1986 | 1987 | 1988 | 1989 | |

|

IWP (Industrial |

184,6 | 193,3 | 208;6 | 219,9 |

| Net profit | 0,7 | 7,8 | 17,6 | 25,7 |

|

Export SW |

53,6 | 47,6 | 62,3 | 70,8 |

|

Export NSW |

5,0 | 5,6 | 6,1 | 7,4 |

|

Consumer goods |

6,8 | 17,0 |

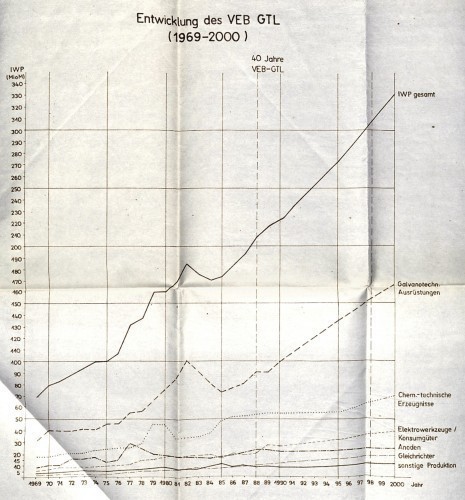

Figure 284 shows a graphical representation of the development of IWP from 1969 to 2000.

Fig. 284: Development of IWP at VEB GTL

Fig. 284: Development of IWP at VEB GTL

In 1988, the year of GTL's fortieth anniversary, this graph shows that IWP had reached around M 230 million and the aim was to increase this to M 330 million by 2000. An ambitious goal that no longer needed to be proven.

Nevertheless, the chart shows us how IWP has developed in recent years. During this period, the workforce was around 1500 employees and has tended to decline in recent years.

Investments

- The new wastewater treatment plant in Plant I begins trial operation in 1986. It is part of the company's environmental protection program and is used by the electroplating department, chemical production and the development laboratory.

- In Knautnaundorf near Leipzig, assembly of the new production facility of the new Plant III begins on September 22, 1986.

In March 1987, the topping-out ceremony for the social building is celebrated. After the assembly and production hall, the shell of the last of the planned buildings is completed,

In March 1988, the first departments of Plant III begin to move into the new plant in Knautnaundorf. In June, the Galvanospiegel reports that the move has been completed.

The investment funds planned for the project were exceeded by M 2.5 million. Instead of the planned 19.1 million M, 21.6 million M were required.

Essentially, the existing machine tools from the old Plant III were relocated. New features included a high-bay warehouse and a circular conveyor system for painting. The social and hygienic facilities were exemplary for the time.

T. Kauerauf published an "Analysis of the performance development of Plant III Knautnaundorf" in 1989 up to 1995. According to his account, the following assessment emerges for the development of industrial goods production. Based on a realistic IWP plan for 1989 of approx. 17 million M, an increase to 40.6 million M by 1995 is possible in the best case, i.e. if the necessary manpower and investments are provided. In the worst case, an increase to M 27.9 million.

Dr. Burkhardt provides an overview of the development of Plant III for the years 1946 to 1989 (see table):

| Year | Personnel | IWP (TM) |

| 1946 | 62 | 400 |

| 1950 | 138 | 1052 |

| 1955 | 178 | 1979 |

| 1960 | 171 | 3089 |

| 1970 | 205 | 6854 |

| 1989 | 156 | 17000 |

It is a remarkable increase over the years that has been achieved in Plant III. Even more so if you consider the development in the number of employees.

40 years of VEB Galvanotechnik Leipzig

GTL celebrates its 40th anniversary on July 1, 1988. Many speeches, events and awards were held to mark the occasion.

These took place on the anniversary day:

- A reception of well-wishers by the state and social leaders in the Plant I culture room. There were 42 so-called greeting addresses from social organizations to Leipzig companies. Of course, representatives of the combine management were also present.

- The workforce in all parts of the plant received a free lunch.

- In the evening, the plant director hosted a festive reception for selected employees at the Hotel Merkur.

The Galvanospiegel also paid tribute to the anniversary in a special edition and was distributed to the workforce together with small gifts via the specialist directors. This special edition celebrates GTL's successes and also reveals that 14 colleagues have been with the company for over 40 years and have therefore already been employed by Langbein-Pfanhauser-Werke AG.

On October 5, there was to be a celebration for all employees in the Congress Hall in Leipzig. This event was canceled at short notice due to structural defects in the congress hall. As compensation for this event, the collectives were provided with "funds for brigade life".

On June 15, 1988, the works group of the KdT (Chamber of Technology) held a festive event to celebrate the fortieth anniversary of GTL in the large cultural hall in Plant I. Several presentations were given on the development of the company. At the beginning of the event, Dr. W. Burkhardt spoke about the history of GTL.

Developments in plant construction 1986 to 1989

Film etching and film forming line

GTL had already designed and produced such systems for the manufacture of aluminum capacitor foils in 1957.

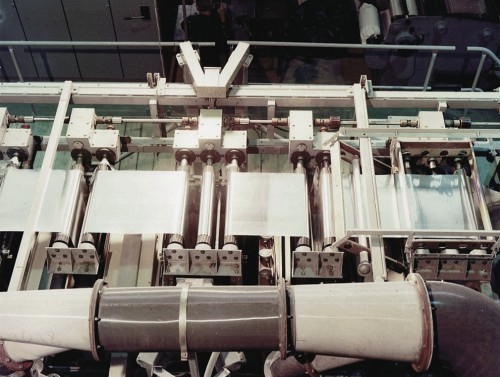

Fig. 285: Foil etching and forming line (detail)

Fig. 285: Foil etching and forming line (detail)

In 1986, the development of the foil etching and forming line for aluminum foil was relaunched together with the Institute for Non-ferrous Metals (NE) in Freiberg. Only one line was produced for the Institute for Non-ferrous Metals in Freiberg (Fig. 285). Production was then discontinued.

KFE / KFN / DGA

As in 1988, special attention was paid in 1989 to the further development and improvement of the copper foil production and post-treatment lines (KFE/KFN) and the wire galvanizing lines (DGA). After all, these were systems that were successful for export, even to non-socialist countries.

There were a large number of technical development requirements for the so-called 4th generation of KFE, the most important of which are listed here:

- Material of the separator cylinders: titanium or titanium cladding on austenitic steel

- Cylinder diameter: 900 mm

- Cathodic current density: approx. 100 A/dm2

- Deposition speed: 52.6 m/h

- Film width: 1200 mm

- Anodes: Lead alloy k

- Film thickness: from 17.5 to 105 µm

- Electrolyte temperature: 70 °C

The product launch of the new development was planned for 1991.

The following development goals were set for the further development of the DGA:

- Minimal wire spacing through the use of insoluble anodes

- Single wire control for current and speed

- Wire diameter up to 10 mm

- Cyanide-free brass electrolyte

- Encapsulation of the system

- Modern auxiliary systems

- Upper container resistant to thermal and mechanical stress

- Modern measuring and control technology.

The further developed DGAs were also to go into production in 1991. Intensive cooperation with SKET Magdeburg (Schermaschinenbau-Kombinat "Ernst Thälmann") was planned for this.

There was extensive cooperation with the VEB Ingenieurbetrieb für Anlagen Berlin SKET for the supply of DGA for the measurement of steel cord wires for the tire industry. A production facility for measured steel cord wires for the automotive industry was to be built at VEB Reifenkombinat Fürstenwalde (RKF) under the main contractorship of SKET to meet the needs of the GDR, Poland and Hungary. The planned investment sum amounted to one billion M. Of this, 250 million M were earmarked for construction, 600 million M for equipment, 4 million VM for NSW special equipment and 150 million M for other items.

At the same time, negotiations were held with Hungary, Bulgaria, China and Yugoslavia for the delivery of complete systems for measuring steel cord wire.

In this context, the further development of the cyanide-free brass electrolyte, which had been discontinued in 1982, was resumed and completed. This electrolyte was tested at VEB Textima und Spezialdraht Mittweida (TSM) in an existing wire plant for bead wires. None of these projects were realized.

Only a new development of the DGA 03 for three wires was presented at the LFM 1989.

Production of galvanizing racks

In 1986, a concept for the production of galvanizing racks was drawn up at GTL. It was common practice for the electroplating shops to manufacture their own plating racks more or less successfully. However, they often lacked the prerequisites for high-quality and therefore electroplating-compatible production of the racks. It was therefore obvious that production should be centralized. However, the project was not implemented as the costs and benefits for GTL were not compatible.

Plastics processing at GTL at a high level

In 1986, GTL was awarded the "Polyplast" challenge cup as the best of 132 plastic processing companies in the GDR. This highest award from the Central Institute for Welding Technology has been presented for 13 years. This award shows the high level of plastic processing at GTL, which is mainly due to the commitment of H. Jung, who is responsible for plastics.

In the GDR, the term "plastic" was used instead of the term "plastic" that is commonly used today.

High-performance technologies

The LEW combine develops a utilization concept for high-performance electroplating technologies. This concept deals exclusively with systems that have the character of a flow cell. These are the KFE/KFN (copper foil production and post-treatment plants), the DGA (automatic wire electroplating machines) and the IVA (internal chrome plating plants). The international technical status, the necessary measures for further development, the importance and the sales opportunities are described. For these tasks a cooperation with the TH Ilmenau, the TU Dresden and the Academy of Sciences in Leipzig was planned.

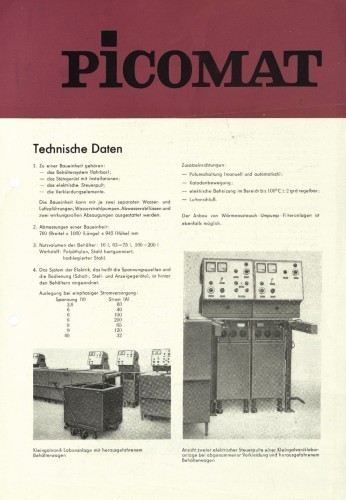

"Picomat"

The small electroplating series "Picomat", which is suitable for research and teaching purposes as well as for the finishing of small series, such as those used in electrical engineering, electronics, optics, precision mechanics, jewelry and watchmaking, was also developed.

watchmaking industry, has undergone continuous further development (Fig. 286).

Fig. 286: Brochure for Picomat

Fig. 286: Brochure for Picomat

The "Picomat" modular system can be used as a program-controlled machine for rack and barrel plating. It was a much sought-after product both at home and abroad.

Patent applications

Between 1986 and 1989, GTL employees registered over 60 patents, mainly from the design department.

Developments in the field of chemical-technical products 1986 to 1989

- Cyanide-free GTL brass electrolyte "CF-D"

This electrolyte was developed together with the Bulgarian Academy of Sciences specifically for coating wires in GTL wire systems. Technical testing was carried out at VEB Textima und Spezialdraht Mittweida. The bead wire produced fulfilled the requirements of TGL 34 194.

- GTL copper electrolyte T100/E11

This electrolyte was used for through-hole plating of printed circuit boards and was comparable with West German products. It was developed in cooperation with the Academy of Sciences in Berlin.

- ANOF

The ANOF process, the anodic oxidationof aluminum by spark discharge, was developed by the TH Karl-Marx-Stadt in the last 10 years. The development was supervised and largely financed by GTL as part of the research cooperation.

This process was used to produce ceramic-like layers on aluminum, which can also be colored. This was advertised in a brochure.

The properties stated in the brochure were determined on a laboratory scale and corresponded to the findings at the time. In 1988, intensive marketing of the ANOF process began at the instigation of the TH Karl-Marx-Stadt.

The process was viewed rather critically at VEB GTL, in Directorate W, as it was not yet fully developed and was not expected to generate large sales in the future.

Nevertheless, numerous trips were made to market the process, particularly to the Federal Republic of Germany.

In August 1988, the foreign trade company Elektrotechnik Export-Import drew up a long-term sales concept that was far removed from reality. The plan was primarily to sell licenses but also systems, although some of the necessary equipment, in particular the voltage source, was not available.

For some years now, the improved process has been offered for special applications by a number of specialist companies under their own company names.

Contract manufacturing for the Elektro-Brite/Trebur company

In 1986, a cooperation with the company Elektro-Brite from Trebur/BRD was initiated. Elektro-Brite wanted contract manufacturing of organic additives for the alkaline zinc electrolyte, which they were unable to realize for capacity reasons. GTL had a technical center for synthesizing organic products and was able to implement Elektro-Brite's ideas.

GTL expected the following benefits from the collaboration:

- Contribution to the realization of NSW exports in the initial amount of 100 TDM/year.

- Rationalization of their own production, among other things through the free provision of stainless steel containers by Elektro-Brite.

- Information about the competition's recipes.

- Use of this information to manufacture own chemical-technical products.

This contract manufacturing was realized in 1987.

GTL did not use the formulation knowledge received and took a license for an alkaline zinc electrolyte from the IChChT in Vilnius, which proved successful after initial teething troubles.

WKC department

In 1986, the long-awaited and overdue reconstruction of the laboratory, the WKC department, began. GTL's research laboratory was in an unacceptable state, the shed roof was leaking in many places, the plaster was falling from the ceiling and it was often unacceptably cold in winter. The sewers were also in urgent need of renovation.

So in November 1996, the laboratory moved with all its equipment, chemicals and furniture into building 35 to free up space for construction.

After two years of construction, the reconstructed R&D laboratory was returned to its employees in 1988 (Fig. 290). It is interesting to note that only one employee of the laboratory can be seen in the photo.

Of the laboratory's former 36 colleagues, only 25 were able to take up their work in the reconstructed rooms due to compliance with legal regulations. The creation of modern laboratory rooms in building 35 was planned for the other employees.

Development in the field of consumer goods and power tools

Due to the permanent shortage of consumer goods of all kinds, companies in the GDR were obliged to produce consumer goods in addition to their main products in order to meet the needs of the population. This production was supposed to account for around 15% of total sales, which was rarely achieved.

For GTL, it made sense to manufacture products that were powered by an engine in particular, as the company had decades of experience in this field.

In 1951, the company began producing low-pressure paint spraying systems, garage compressors, hand sanders, support sanders and disc sanders.

In the course of time, the electric household coffee grinder, the hand drill, the drill stand, an aeration pump for aquariums, the bench grinder, the fruit juicer, a circular saw attachment, a jointer, a grinding device for saw blades, a band saw and a bench grinder were added. Most of these products were further developed, some were outsourced and transferred to other companies for further production.

In the Neckermann catalog, for example, the bench grinder could be ordered under the name "Bullkraft". This means that the demand for these products could not be met by GTL, even if some of them could be sold for hard currency, albeit at low prices, due to their good quality.

The production of products for the population has a long tradition at the GTL site. As early as 1900, Langbein produced a drill with three gears and LPW manufactured chargers and motorized air pumps for automobiles in the 1930s.

Company history

In 1987, a concept for researching the company history of GTL was drawn up. H.-J. Krosse was the secretary of the company history commission, which was constituted on November 23, 1987.

The "Guidelines for researching and promoting company history" were published in the magazine "Neuer Weg" as early as 1977. E. Honecker also addressed this issue in his speech to the first district secretaries on February 17, 1978, which led to the formation of company history commissions in many companies.

It is not possible to clearly define when GTL's awareness of history was awakened, as there was already a tradition cabinet in the company in the corridor leading to the party leadership in Building 1 before the above-mentioned conception.

The history commission planned three main areas of focus, each with 100 pages, for the development of the GTL history,

Quote:

"Part I:

The historical activity and situation of the workers of the enterprise under the conditions of capitalism, their struggle against exploitation and oppression, against imperialism, militarism, fascist dictatorship and war, for democratic rights and social progress, their role in production and in the development of the productive forces (period 1890 to 1945).

Part II:

The new social position of workers and other laborers on the basis of socialist power and property relations; their historical achievement in the transition period from capitalism to socialism and in the construction of the developed socialist society under the leadership of the party of the working class, the conscious and creative action of factory workers in the development of production, in increasing productivity and effectiveness, in mastering scientific and technological progress (period 1945-1960)

Part III:

The contribution of the electroplating technicians under the leadership of the company party organization in the development of the company into a modern socialist large-scale enterprise and important partner of the national economy. The type and scope of production; the continuous development of the productive forces in the enterprise, the realization of the main task in its unity of economic and social policy as well as the raising of the material and spiritual standard of living. The leading role of the SED in the enterprise and the work and activity of democratic socialist mass organizations to further develop the creativity of the working people (period 1961 to present)."

For the technically trained, it is certainly difficult to fill these points with life. It was the usual journalistic style of the time.

I was able to evaluate and use the documents collected by the company history commission, which a colleague had kept and thankfully handed over to me, for my work on the documentation "Leipzig - the cradle of electroplating in Germany".

Events at the end of 1989

With the demonstrations in Leipzig and ultimately the fall of the Berlin Wall on November 9, 1989, major changes also took place in the companies. Some of the events at GTL are reported below in chronological order.

Ceremonial address by the plant director on the 40th anniversary of the GDR

It was customary for the plant director to give a celebratory speech on social occasions.

These speeches were general phrases about world peace, the victory of socialism, friendship with the Soviet Union and the like. But they were also a good opportunity to recognize employees for good performance.

In 1989, however, there was a special feature due to the events. The speech was written by speechwriter K. Gehmlich on 29.09.1989 and was to be held on 14.10.1989. As events came thick and fast during these 14 days, changes were made to the speech at short notice. Not only was the speech shortened, but passages such as "With pride, our people enter the fifth decade of the GDR in good spirits" were also removed.

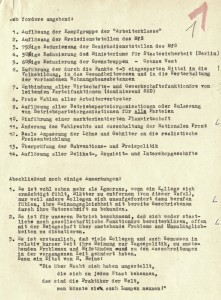

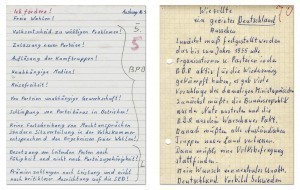

Notice board/showcase

In the course of the upheavals taking place, a bulletin board was set up at GTL on November 1 at the entrance to the dining hall, where every employee could express their opinion.

could express their opinion. The notices, which could not be anonymous, were taken twice a week by the head of the plant manager's office and passed on to the relevant directorates for replies or comments. By the end of December, more than 80 notices of all kinds had been posted on every conceivable topic, from internal problems to national political issues. The draft travel law of 6.11.1989 was also heavily discussed and criticized. At the end of December, responsibility for the bulletin board was handed over to the New Forum.

Three examples of these postings are shown on the front pages (Fig. 287 to 289).

The demands in this first poster are not yet as radical as they will be in the following ones. German unity was also not the number one topic at the beginning, but this was to change within two months.

Galvanospiegel

As the editor of Galvanospiegel starts studying at the district party school, the last Galvanospiegel is published on August 18, 1989. Publication did not resume until November 24 with issue no. 16 under the old editor. The events of the time probably spoke against studying at a party school.

It can be said that the company newspaper has never been as interesting as it will be from its reappearance until its last issue, number 8, in September 1990.

The critical articles increase in the following issues. There are pros and cons about the general situation and the future of GTL and the GDR. Thanks to the editor, however, the discussion is conducted very objectively.

Number 16 still has the familiar headline with the subtitle "Organ der Betriebsparteileitung des VEB Galvanotechnik Leipzig" ( Fig. 291).

In issue 17, the subtitle changes to "Company newspaper of the workers of VEB Galvanotechnik Leipzig" (Fig. 292).

GTL works group of the NEUEN FORUM formed on November 6

The New Forum published the following excerpt:

Spokesperson for public relations elected:

"On November 6, 1989, about 20 members of the New Forum met at 4 p.m. at our plant for an initial brief consultation. The aim was to get to know each other, to form a company group and to discuss initial ideas for the work of this group, primarily in our company. Furthermore, a spokesperson group was elected, consisting of four colleagues, and it was pointed out that only these four were allowed to speak in public on behalf of the works group in order to prevent misuse in the name of the New Forum. All appeals and communications distributed by us must therefore bear the signature of at least two of the four spokespersons."

The works group of the New Forum at GTL was very active. The work program was published on 16.11.1989.

As can be seen from the program, the following priorities were set:

- Economy, science and technology

- Ecology and the environment

- Trade union work, state and legal affairs

- Youth and education and

- media and cultural policy.

A general meeting should be held on a monthly basis.

INFO

Selected national and international events

25.2.1985:

At the XXVII Party Congress of the CPSU, Mikhail Gorbachev (General Secretary of the CPSU since March 11, 1985) calls for "glasnost" (openness: more freedom of speech, opinion and press in the country) and perestroika (restructuring). He announces radical reforms in the economy.

17.4.1985:

At the XI Party Congress of the SED in Berlin, Gorbachev calls on the delegates to be self-critical.

26.4.1985:

The Chernobyl nuclear disaster begins with the explosion of Block 4 of the nuclear power plant.

18.9.1985:

The GDR tightens entry regulations, reducing the number of asylum seekers entering the FRG via East Berlin.

7.9.1986:

Erich Honecker is the first GDR head of state to visit the Federal Republic of Germany.

19.10.1987:

On so-called Black Monday, there is a stock market crash in the western world, with share prices plummeting by more than 20% in one day.

10.4.1987:

In an interview with the West German magazine "Stern", Kurt Hager compares perestroika to a change of scenery that you don't have to go through as a neighbor.

25.8.1987:

Signing of the agreement on scientific and technical cooperation between the GDR and the FRG.

1987:

The first ATMs are put into operation in Leipzig.

2.2.1988:

According to an internal MfS (Ministry for State Security) report, there are 800 right-wing extremist skinheads in the GDR.

18.11.1988:

The German edition of the Soviet monthly magazine "Sputnik" is removed from the postal newspaper list. This is effectively a ban.

2.12.1988:

Erich Honecker declares his rejection of the Soviet reform policy at a meeting of the SED Central Committee.

Works council of the SED

On December 6, 1989, plant director F. Tätzner and party secretary P. Richter agree to vacate the premises used by the SED. The rooms and inventory were handed over on December 29. The inventory, a "Strelasund" radio, a five-piece wall unit, a "Pentacon six" camera with accessories, a record player, a tape recorder, a television, a coffee machine, a refrigerator and an "Optima 202" electric typewriter were handed over to the company newspaper editorial office on December 29, 1989. This fulfilled one of the main demands of the black board.

A company party leadership was no longer necessary anyway, as most of the comrades had already left the party in October and November.

party in October and November.

Note:

The author, who is documenting the history of electroplating at the Leipzig site, is still looking for further information and documents from Galvanotechnik Leipzig and from LPW or its predecessor companies Dr. Georg Langbein, Leipzig and Wilhelm Pfanhauser, Vienna.

If you have any such documents or equipment, he would be grateful if you would contact him.

In addition to the walks in this series, which provide a greatly abridged presentation, the author has published richly illustrated, cloth-bound treatises entitled "Leipzig - the cradle of electroplating in Germany" in collaboration with the association

"Deutsches Museum für Galvanotechnik e.V.".

Volume I with 188 pages, which describes the life and work of Wilhelm Pfanhauser and Dr. Georg Langbein, was published in June 2016.

As the first edition was quickly sold out, a second corrected edition of Volume I with a foreword by two great-grandsons of Wilhelm Pfanhauser Sr. was published in December 2016 and is also no longer available

Volume II with 446 pages, which deals with the history of LPW from 1907 to 1948 at the Leipzig site, was published in fall 2017 and is also already out of print.

Volumes I and II have been reprinted so that these volumes are available again.

In November 2018, Volume III was published with over 465 pages, providing information about VEB Galvanotechnik Leipzig in the period from 1949 to 1980.

The final volume IV, which continues the history of Galvanotechnik Leipzig for the years 1981 to the end of 1993 and beyond, provides information on other specialist companies in the Leipzig area from 1890 to 1945, reports on the Leipzig-based publishers for electroplating technology Eugen G. Leuze and F. Ernst Steiger until 1945 and contains the bibliography with 1793 references, was published in November 2019.

It can be assumed that these four volumes represent one of the most comprehensive documentations of an industrial location in Leipzig.

The books are distributed by the association:

"Verein Deutsches Museum für Galvanotechnik e. V."(www.vdmg.de). You can find more information here.

For the German Museum of Electroplating, which was founded in Leipzig in February 2010 and celebrated its tenth anniversary this year, we are always looking for exhibits (pictures, books, plant models, small plants, process engineering documents, company publications, electroplated parts, etc.), also from more recent times. We would be delighted if you would support us in the further development of the museum.

Please write to:

THE AUTHOR

Dr. Ulrich Vieweger

studied chemistry at the engineering college in Köthen and the university in Halle after completing an apprenticeship as an electroplater at VEB Galvanotechnik Leipzig and gained his doctorate at the Ilmenau Technical University.

He worked in research at Galvanotechnik Leipzig and was Managing Director of the Chemistry Division from 1990 to 1992. He was then responsible for sales in eastern Germany, Poland, the Czech Republic and Slovakia for Blasberg Oberflächentechnik GmbH until his retirement in 2007.