Because it only contributes to the actual added value to a limited extent, deburring is a little-loved and little-studied machining process. Deburring is not common for plastic parts because injection molding, for example, produces burr-free workpieces. Nevertheless, deburring is necessary in many cases. A two-part article on the basics, materials and processes.

Jet cutting

![Abb. 13: Trommel einer Schleuderradstrahlanlage zur Umwälzung der Teile [27] Abb. 13: Trommel einer Schleuderradstrahlanlage zur Umwälzung der Teile [27]](/images/stories/Abo-2022-08/thumbnails/thumb_gt-2022-08-0032.jpg) Fig. 13: Drum of a wheel blast machine for circulating the parts [27] Based on the mentions and technical reports in the literature, shot blasting is used more frequently than vibratory finishing for deburring plastic and rubber. This process must be subdivided into the compressed air and wheel blasting known from metalworking and the blasting of workpieces supercooled with dry ice or liquid nitrogen (see following section). In contrast to the blasting of metals, plastic granulate is usually used as a blasting medium for plastics in addition to dry ice, because metallic or synthetic blasting media such as chilled cast iron or corundum would remove too much from plastic parts, even when undercooled.

Fig. 13: Drum of a wheel blast machine for circulating the parts [27] Based on the mentions and technical reports in the literature, shot blasting is used more frequently than vibratory finishing for deburring plastic and rubber. This process must be subdivided into the compressed air and wheel blasting known from metalworking and the blasting of workpieces supercooled with dry ice or liquid nitrogen (see following section). In contrast to the blasting of metals, plastic granulate is usually used as a blasting medium for plastics in addition to dry ice, because metallic or synthetic blasting media such as chilled cast iron or corundum would remove too much from plastic parts, even when undercooled.

The process is discussed in particular detail in [27] with several systems and many processing examples. Several machine concepts are described, which accelerate the blasting medium both with compressed air and with blast wheels and have different degrees of automation depending on the series sizes of the workpieces. Wire belts, so-called loop belts, turning beams or turning tables as well as a multi-segmented drum with wave-shaped drivers are used to transport the workpieces through the machines for thorough but gentle circulation of the parts (Fig. 13).

Polyamide (PA) and polycarbonate (PC) are used as blasting media, natural products made from nutshells or fruit stones as well as thermoset granulates for particularly gentle processing. A polyamide granulate suitable for deburring thermoset parts is described in more detail in [28]. Based on polyamide 6 with a density of 1.14g/cm3 and a Mohs hardness of around 2 to 3 or a Rockwell hardness of 96, grain sizes between 0.2 and 3 mm are available in many gradations. The abrasives are usually provided with an antistatic agent to prevent electrostatic charging and dust formation. As the effect of the agent sometimes wears off, it must be added again during use or at regular intervals. In addition, an abrasive treatment is required that enables the screening out of blasted material particles or the removal of dust by air separation.

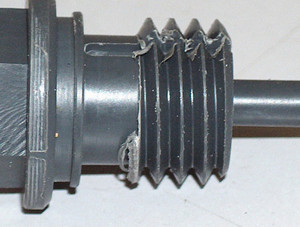

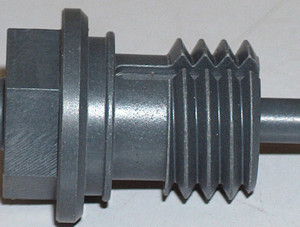

Some very good examples of this process can be found in [6], e.g. in Figures 14 and 15 the two parts with burrs from Figures 8 and 9, which were deburred by blasting. However, parts from the injection molding process can also be processed in critical areas in this way. In any case, granulates can be used as blasting media to avoid roughening the surface of the parts. This depends, among other things, on the combination of part material and blasting medium material. For most thermoplastics, polyamide will be the most suitable because this plastic tends to be soft and tough, yet wear-resistant. In addition, the process parameters must be adapted and for applications in the form shown, smaller grain sizes of the blasting media and an air pressure for accelerating the granulate grains in the range of 1 to 3 bar are more suitable.

Fig. 14 and 15: Plastic parts deburred by blasting [6]

Blasting with dry ice (CO2)

SolidCO2 has been used for several years to clean sensitive surfaces that must not be altered by blasting. The equipment available on the market is very versatile and ranges from stationary to mobile systems that can be transported to the "construction site". The solidCO2 dry ice at -78.5°C can be delivered to the processing site by suppliers, but there are also devices that produce the "powder" on site, whereby the grain size can be adjusted by the grinder, e.g. for grain sizes in the tenth of a millimeter range (Fig. 17).

Fig. 16: Injection molded part with burr and deburred by blasting [6]

The advantage of using this material for shot blasting, in addition to its low hardness (similar to plaster), which prevents damage to the surfaces, is the residue-free operation, as theCO2 mixes with the ambient air after expansion and only the cleaned residues or burr residues need to be disposed of. The cleaning effect is not only based on the kinetic energy of the pellets accelerated with compressed air, but is also supported by the embrittlement caused by the cold. In addition, during the phase transition of theCO2 snow from solid to gaseous, an increase in volume occurs. This creates micro-pressure waves that propagate at high speed [30] and mechanically process the burr or contamination. This results in deburring without changing the surfaces (Fig. 18).

Cryogenic deburring

The blasting of supercooled parts was initially developed and used for rubber parts, but is now also used for thermoplastics and parts made of non-ferrous metals. The obvious reason for the development of this process variant is the fact that rubber parts are very soft and ductile at room or application temperature, but become hard and brittle at very low temperatures, well below their glass transition temperature. This makes it very easy to break off the thin flitter burrs and webbing that are almost unavoidable with rubber. This variant of deburring by blasting uses the effect of cold as previously described for blasting withCO2 snow, but plastic granulate is again used as the blasting medium and the cold is brought about with liquid nitrogen, which is usually sprayed onto the workpieces when the deburring chamber is full.

Fig. 20 to 22: Injection molded parts made of rubber materials that have been deburred with subcooling using liquid nitrogen and blasting with granulate or in drums [21]

In individual cases, steel shot with a grain size of around 0.2 or 0.3 mm is used as granulate in this process variant [32], but usually polycarbonate (PC) is used because this plastic has very low moisture absorption and good low-temperature resistance of up to -150°C [30]. The grain sizes here are 0.3 to 1.5 mm. If a blast wheel is used, it rotates at a speed of between 1,000 and 8,500 rpm [23] and a processing temperature of around -140°C is selected. Other sources mention a larger range between -20 and -120°C and also describe that residual burrs on molded rubber parts are processed in drums, supercooled by nitrogen, but without granulate and only by circulation [32]. In addition to other materials that are deburred, e.g. the plastics and composite materials PEEK, PTFE, PVDF, PE, POM, PPS-GF/GB, PBT-GF/GB, Ryton, CFRP, carbon, [4] also specifically lists the rubber materials that can be processed by cryogenic deburring: EPDM, NBR, AEM, HNBR, FKM, NR, VMQ, LSR, PU, Viton® (FKM), etc. For this purpose, systems are available that are equipped with all the facilities required for cooling with liquid nitrogen and have chamber volumes of between 10 and 150 liters for blasting systems (Fig. 19) and up to 400 liters for barrel systems [31, 33]. Some impressive examples can be found in [21] (Fig. 20 to 22).

Deburring with heat

Because thermoplastics, unlike metals, can be softened at relatively low temperatures, it is also possible to use this property for a deburring process.

![Abb. 23: Kombination aus Lufterhitzer, Gebläse und Temperaturregler zum Entgraten von Kunststoffen vorzugsweise entlang einer Werkzeugtrennfuge o. ä. [34] Abb. 23: Kombination aus Lufterhitzer, Gebläse und Temperaturregler zum Entgraten von Kunststoffen vorzugsweise entlang einer Werkzeugtrennfuge o. ä. [34]](/images/stories/Abo-2022-08/gt-2022-08-0043.jpg) Fig. 23: Combination of air heater, fan and temperature controller for deburring plastics, preferably along a mold parting line or similar. [34]

Fig. 23: Combination of air heater, fan and temperature controller for deburring plastics, preferably along a mold parting line or similar. [34]

Hot air from a fan or flame can be used to melt down burrs, as can radiant heat. With a combination of air heater, blower and temperature controller (Fig. 23), it is possible to position small parts completely in the hot air jet using a handling device or to move large parts with the seam along the blower. The temperature and traversing speed must be set for each workpiece. The results with this technique are then so uniform that close monitoring is no longer necessary [34, 35]. In this way, for example, the tool parting line of the "Bobby Car" children's car produced by extrusion blow molding is automatically deburred with a robot [36]. The method using infrared emitters is somewhat more complicated, but also has advantages. Such emitters heat the area of the plastics adjacent to them very quickly within 4 to 12 seconds without contact [37]. A special feature is the precise contour adjustment of the emitter to the workpiece geometry or along the burr line (Fig. 24 and 25), so that no relative movement is required between the workpiece and the emitter. Point emitters via light guides with diameters of 2 to 5 mm are also available. The burr is fused with the surrounding contour in such a narrow area that it is no longer recognizable in most cases. This is possible because a relatively large amount of energy is transferred in a short time over a distance of approx. 20 mm from the workpiece, for example a nominal power of 10.4 kW for a glove compartment housing [38]. In this example, it was determined that the power over a longer period of time with infrared radiators is only 8.7 watt hours and 42.5 watt hours with hot air for the same contour. However, it must be noted that the plastics are differently suited to this process. Types such as PE, PMMA, ABS or the synthetic rubber EPDM can be processed very well, whereas thermosets cannot. This process is just as unsuitable for thermoplastics filled with glass fibers, because although the matrix is melted in, the glass fibers do not change and remain at the burr line.

Fig. 24 and 25: Airbag housing and blow-moulded casting can with contour-matched infrared emitters for deburring the edges or the mould parting line [37, 39]

Thermal-chemical deburring

![Abb. 26: TEM-Entgratanlage für Kunststoffe [40] Abb. 26: TEM-Entgratanlage für Kunststoffe [40]](/images/stories/Abo-2022-08/thumbnails/thumb_gt-2022-08-0046.jpg) Fig. 26: TEM deburring system for plastics [40]Even if it sounds rather unlikely at first, thermal-chemical deburring (TEM, also known as "explosion deburring") has become established as a good process for plastics in the last decade. In this process, the workpieces are placed in bulk or, if they are sensitive, in holders in a chamber in the machine (Fig. 26), where they are sealed airtight. A gas-oxygen mixture is then introduced and ignited. This generates temperatures of up to 3,000°C within a few milliseconds and the burrs are burnt due to their "unfavorable" ratio of surface area to volume, because there is not enough volume to dissipate the heat.

Fig. 26: TEM deburring system for plastics [40]Even if it sounds rather unlikely at first, thermal-chemical deburring (TEM, also known as "explosion deburring") has become established as a good process for plastics in the last decade. In this process, the workpieces are placed in bulk or, if they are sensitive, in holders in a chamber in the machine (Fig. 26), where they are sealed airtight. A gas-oxygen mixture is then introduced and ignited. This generates temperatures of up to 3,000°C within a few milliseconds and the burrs are burnt due to their "unfavorable" ratio of surface area to volume, because there is not enough volume to dissipate the heat.

The machine has a chamber with a base area of 420 mm square and a height of 800 mm, in which either larger parts or many parts together can be deburred [40]. The special features for plastics processing lie in the choice of fuel gas. While methane is usually used for metals, plastics are deburred with hydrogen. In addition, plastics are operated with significantly less pressure in the chamber, i.e. in contrast to steel, where up to 50 bar is used, the pressure for plastics is in the single-digit range up to a maximum of approx. 40 bar. The chamber is evacuated before ignition in order to prevent contamination from the ambient air and to be able to work safely at the lower pressure.

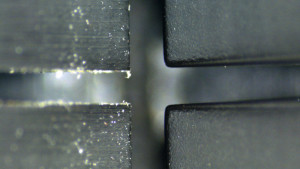

The following plastics can be deburred particularly well: PMMA, POM, PA, cast PA, PUR, ABS, PE, PP, silicone, laser-sintered materials, NBR and Viton® [40]. Examples show the good deburring quality without damaging the remaining surface (Fig. 27a and b). Another special feature of Plexiglas (PMMA) is the thermal polishing that occurs automatically with this deburring method (Fig. 28 and 29). If this material is processed mechanically or by cutting, the surfaces are no longer glossy, but comparatively rough and no longer transparent due to the chip residue. These still firmly adhering particles are also melted down by the heat treatment and the parts are smooth and transparent in accordance with the material.

Fig. 27a and b: Plastic parts deburred by TEM [41]

Conclusion:

The investigation has shown that many of the processes used for deburring metals are also suitable for plastics, and in all cases they have been adapted to suit the material. Without further mentioning the manual deburring processes, the abrasive media and grinding additives are generally adapted to the plastics in mass finishing, softer abrasives are used in shot blasting and reduced pressure and a more suitable gas are used in TEM deburring. However, this also means that not all machines that may already be available in a company for metal processing would be ready for use with plastics without further ado. In many cases, it will not be enough to simply replace the abrasives or blasting media; the machines must also be able to run the parameters suitable for plastics. On the other hand, new processes have also been developed and refined in the plastics sector that did not previously exist in metalworking and thus prepared for series production, such as subcooling with liquid nitrogen or deburring with heat. But synergy effects were also evident here, as the blasting of undercooled parts is also suitable for non-ferrous metal casting.

As far as materials are concerned, thermoplastics can only be machined with such processes in special cases, thermosets and elastomers almost always and many special features must be taken into account for fiber-reinforced materials and some of the processes described are not suitable here either.

With the processes listed, techniques are also available for the production of plastic parts that are suitable for large-scale production from both a technical and an economic point of view, although burr avoidance is always the more favorable solution.

Literature

[27] N. N.: Throughfeed blasting technology for plastic deburring, company publication of Rösler Oberflächentechnik GmbH, Untermerzbach, Publ.-No. DE.186/07, 04.2019

[28] N. N.: Thermoset deburring with polyamide 6, flyer from Rifatec GmbH, Viersen, no year

[29] N. N.: Deburring and cleaning with dry ice (CO2 solid), website of OKS GmbH, Großbottwar, (viewed on 19.9.2021)

[30] N. N.: Drying, deburring and cleaning with CO2, Kunststoff-Magazin, No. 7, 2019, 24-25

[31] N. N.: Image brochure of AW Maschinen- und Anlagentechnik GmbH & Co KG, Finnentrop, (downloaded on 21.9.2021)

[32] N. N.: Your manufacturing specialist for technical molded rubber parts, company presentation of Knorr & Macho GmbH, Kirchheim unter Teck, 2018, (viewed on 21.9.2021)

[33] N. N.: Blast cleaning system Flash S70, Kunststoffe, No. 10, 2006

[34] N. N.: Automated deburring of plastic parts with hot air, Flyer of Leister Process Technologies, Sarnen, Switzerland, September 2007

[35] N. N.: Thermal deburring, website of HAPRO Industriegeräte GmbH, Solingen, https://www.hapro.de/prozesse/thermisches-entgraten/ (viewed on 22.9.2021)

[36] N. N.: How a BIG Bobby-Car is made: Around the world on four wheels, film on production, https://www.youtube.com/watch?v=2Q2EKxzXnyQ, more detailed at https://www.big.de/de/videos/ (viewed on 22.9.2021)

[37] Königsreuther, P.: Fix deburring or welding of even complex designed plastic parts, Maschinenmarkt-online zur K2019, 18.7.2019, (viewed on 22.9.2021)

[38] N. N.: Infrared emitters efficiently deburr glove boxes and door handles, flyer from Heraeus Noblelight GmbH, Kleinostheim, April 2017

[39] N. N.: Infrared emitters - Adapted to the workpiece, KEM at Fakuma 2014, 29.9.2014

[40] Schulz, D.: Thermal deburring of medical products, Plastverarbeiter, No. 10, 2017, 148-150

[41] N. N.: Thermal deburring of plastic, website of moser-entgratungs ag, Thörigen, Switzerland, 05/2018 (viewed on 22.9.2021)

![Abb. 17: CO2-Pellets zum Entgraten durch Strahlspanen [29] Abb. 17: CO2-Pellets zum Entgraten durch Strahlspanen [29]](/images/stories/Abo-2022-08/thumbnails/thumb_gt-2022-08-0037.jpg)

![Abb. 18: Werkstück aus dem Spritzgießprozess durch CO2-Schnee entgratet [30] Abb. 18: Werkstück aus dem Spritzgießprozess durch CO2-Schnee entgratet [30]](/images/stories/Abo-2022-08/thumbnails/thumb_gt-2022-08-0038.jpg)

![Abb. 19: Schleuderradstrahlanlage AWS 08 / AWS08+ für kryogenes Entgraten von Gummiteilen [31] Abb. 19: Schleuderradstrahlanlage AWS 08 / AWS08+ für kryogenes Entgraten von Gummiteilen [31]](/images/stories/Abo-2022-08/thumbnails/thumb_gt-2022-08-0039.jpg)

![Abb. 28: Plexiglasteil nach der spanenden Bearbeitung (oben) und nach dem Entgraten durch TEM (unten) [40] Abb. 28: Plexiglasteil nach der spanenden Bearbeitung (oben) und nach dem Entgraten durch TEM (unten) [40]](/images/stories/Abo-2022-08/thumbnails/thumb_gt-2022-08-0049.jpg)

![Abb. 29: Plexiglasteil nach der spanenden Bearbeitung (rechts) und nach dem Entgraten durch TEM (links) [41] Abb. 29: Plexiglasteil nach der spanenden Bearbeitung (rechts) und nach dem Entgraten durch TEM (links) [41]](/images/stories/Abo-2022-08/thumbnails/thumb_gt-2022-08-0050.jpg)