Additive manufacturing techniques in medical applications are becoming increasingly complex and allow the production of customized medical devices. Three examples are described below: individual microscopic objects printed using ultrasound, pharmaceutical tablets printed on site using additive manufacturing and laser-printed self-dissolving implants.

3D printing with ultrasound [1]

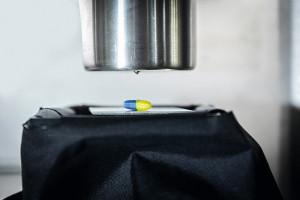

Fig. 2: Two print heads work together in the prototype. When fully expanded, up to eight print heads could be integrated into the systemScientistsfrom the "Micro, Nano and Molecular Systems" research group at the Max Planck Institute for Medical Research and the Institute for Molecular Systems Engineering and Advanced Materials at Heidelberg University have developed a new technology for printing matter in 3D. They use sounds, or sound waves, to generate printing fields (Fig. 1). Within these sound fields, for example, solid particles or biological cells can be assembled into selected shapes. The findings pave the way for novel 3D cell culture techniques with high relevance for biomedical technologies. The results of the study were published in Science Advances on February 8 [2].

Fig. 2: Two print heads work together in the prototype. When fully expanded, up to eight print heads could be integrated into the systemScientistsfrom the "Micro, Nano and Molecular Systems" research group at the Max Planck Institute for Medical Research and the Institute for Molecular Systems Engineering and Advanced Materials at Heidelberg University have developed a new technology for printing matter in 3D. They use sounds, or sound waves, to generate printing fields (Fig. 1). Within these sound fields, for example, solid particles or biological cells can be assembled into selected shapes. The findings pave the way for novel 3D cell culture techniques with high relevance for biomedical technologies. The results of the study were published in Science Advances on February 8 [2].

3D printing enables the production of complex parts from various materials, even biological ones. Conventional 3D printing can be a slow process in which objects are built up layer by layer. Heidelberg and Tübingen have now shown how to form a 3D object from smaller building blocks in just one step.

Using targeted and shaped ultrasound, the smallest particles could be assembled into a three-dimensional object in a single step. This can be very useful for so-called bioprinting. The cells used there are particularly sensitive to environmental influences and ultrasound is a gentle method. Sound waves exert forces on matter - a fact that every concertgoer who experiences the pressure waves of a loudspeaker knows. With high-frequency ultrasound, which is inaudible to the human ear, the wavelengths can be shifted below one millimeter into the microscopic range, which researchers use to manipulate very small building blocks such as biological cells. In previous studies, Peer Fischer et al. showed how ultrasound can be generated using acoustic holograms - 3D-printed plates designed to encode a specific sound field. They demonstrated that these sound fields can be used to assemble materials into two-dimensional patterns. With their new study, the team was able to take the idea one step further. In the sound fields, they capture particles and cells floating freely in the water and assemble them into three-dimensional shapes. In addition, the new method works with a variety of materials, including glass or hydrogel beads and biological cells. The key idea was to use several acoustic holograms together to form a sound field that can capture the particles. Digitizing an entire 3D object into ultrasonic hologram fields is very computationally intensive and required new computational routines. The scientists believe that their technology represents a major advance for the formation of cell cultures and tissues in 3D. The advantage of ultrasound is that it is gentle on cells and can penetrate deep into the tissue. This means that the new method can be used to manipulate cells remotely without causing damage.

3D printing for pharmacies or hospitals [3]

Fig. 3: The prototype of the novel 3D printer in the laboratory for manufacturing systemsHighlyindividualized drugs from the 3D printer could increase treatment success, reduce side effects and improve therapy adherence. In order to make this technology more accessible and attractive for pharmacies or hospitals, for example, PolyPrint - a consortium of TH Köln, Heinrich Heine University Düsseldorf (HHU), Merck KGaA and Gen-Plus GmbH & Co. KG - has developed a new type of 3D printer and optimized polymers. The newly developed pharmaceutical polymers processed with the system are suitable for two processes: hot melt extrusion and fused deposition modeling, which form the basis of the new 3D printing process. In hot melt extrusion, plastics are melted, mixed with the active pharmaceutical ingredients and processed into long filaments. Fused deposition modeling is a 3D printing technology in which the filaments are melted a second time in the print head and formed into tablets. The requirements for the new polymers include high water solubility, low processing temperature and high thermal stability.

Fig. 3: The prototype of the novel 3D printer in the laboratory for manufacturing systemsHighlyindividualized drugs from the 3D printer could increase treatment success, reduce side effects and improve therapy adherence. In order to make this technology more accessible and attractive for pharmacies or hospitals, for example, PolyPrint - a consortium of TH Köln, Heinrich Heine University Düsseldorf (HHU), Merck KGaA and Gen-Plus GmbH & Co. KG - has developed a new type of 3D printer and optimized polymers. The newly developed pharmaceutical polymers processed with the system are suitable for two processes: hot melt extrusion and fused deposition modeling, which form the basis of the new 3D printing process. In hot melt extrusion, plastics are melted, mixed with the active pharmaceutical ingredients and processed into long filaments. Fused deposition modeling is a 3D printing technology in which the filaments are melted a second time in the print head and formed into tablets. The requirements for the new polymers include high water solubility, low processing temperature and high thermal stability.

The prototype developed for the new 3D printer works with two print heads (Fig. 2). These can process filaments with different active ingredients and print a tablet one after the other or alternately. When the system is fully expanded, up to eight print heads can be integrated. The device meets the requirements of "Good Manufacturing Practice" in accordance with the EU GMP guidelines for systems in pharmaceutical production. The print area is therefore completely encapsulated and all components that come into contact with material can be easily removed and cleaned. The water-cooled print head is also suitable for brittle filaments.

The extruder, which mixes polymers and active ingredients, is central to the processing step from polymer to tablet (Fig. 3). This was configured in such a way that even at very low dosages of 0.1 percent active ingredient, filaments are produced that are completely homogeneous so that each tablet contains the same amount of active ingredient. The printing and temperature conditions in the print head were also analyzed.

Fig. 4: The system processes filaments with different active ingredients, which are printed one after the other or alternately to form a tabletIndividuallyprinted medicines also make it possible to control the release of the active ingredients into the body, for example via certain geometries or surfaces. As an example, the project partners developed a tablet for the treatment of Parkinson's disease with three active ingredients. This was designed in such a way that the active ingredients are released from the tablet one after the other and thus have an optimal, coordinated effect during treatment.

Fig. 4: The system processes filaments with different active ingredients, which are printed one after the other or alternately to form a tabletIndividuallyprinted medicines also make it possible to control the release of the active ingredients into the body, for example via certain geometries or surfaces. As an example, the project partners developed a tablet for the treatment of Parkinson's disease with three active ingredients. This was designed in such a way that the active ingredients are released from the tablet one after the other and thus have an optimal, coordinated effect during treatment.

The new technology could be used in pharmacies or hospitals (Fig. 4). The new 3D printer and the filaments with the polymer-drug mixture should be easy to use and quick to learn. The printed medicines could be used to treat infants and children, for example, for whom medication doses have to be adjusted in very small steps due to their rapid growth. The process could also be used in precision medicine, where drugs are tailored precisely to the patient. Batch sizes of between one and one hundred tablets are possible.

Self-dissolving medical devices [4]

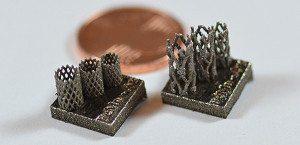

Whether bone screws, plates or stents - implants are used in German hospitals every day. However, it is not uncommon for these to have to be removed in a follow-up operation, for example in children and adolescents, as their bones are still growing. But every further operation carries a risk and costs money. In 2010, 180,000 operations were carried out in Germany for the sole purpose of removing orthopaedic implants. This makes it the fourth most common orthopaedic operation of all. One possible solution: stents and the like, which are broken down and metabolized by the body after a few weeks or months, depending on the application. These medical devices are still rarely used - an interdisciplinary team at Paderborn University is working on developing efficient implants (Fig. 5).

Fig. 5: Prototype of a stent made of a mixed iron-manganese-silver material produced by the Chair of Materials Science using LPBF compared to a 1-cent coinThechallenge is to find materials that are stable enough and last as long as the body needs them to heal, and which then degrade easily and, above all, in a controlled manner. Research is currently focusing on iron, magnesium and zinc. Pure iron dissolves extremely slowly, magnesium extremely quickly. Zinc itself corrodes well, but its strength is often insufficient. Researchers around the world are searching for the perfect alloy, the optimum implant for the respective application. In addition to the field of application, biocompatibility - i.e. compatibility with the body - production and manufacturing costs must also be taken into account.

Fig. 5: Prototype of a stent made of a mixed iron-manganese-silver material produced by the Chair of Materials Science using LPBF compared to a 1-cent coinThechallenge is to find materials that are stable enough and last as long as the body needs them to heal, and which then degrade easily and, above all, in a controlled manner. Research is currently focusing on iron, magnesium and zinc. Pure iron dissolves extremely slowly, magnesium extremely quickly. Zinc itself corrodes well, but its strength is often insufficient. Researchers around the world are searching for the perfect alloy, the optimum implant for the respective application. In addition to the field of application, biocompatibility - i.e. compatibility with the body - production and manufacturing costs must also be taken into account.

At Paderborn University, scientists from the fields of technical and macromolecular chemistry and materials science are researching iron-manganese alloys, as pure iron would take far too long to dissolve. There is great potential in iron-manganese alloys, as the combination of mechanical properties, biocompatibility and corrosion rates is very promising. However, if you want to develop medical products, you also have to consider the physiological environment. For example, body fluids are simulated and the samples are tested in experiments.

In a recently published study [5] in the journal "Materials and Corrosion", Paderborn scientist Jingyuan Huang and her colleagues analyzed the surface corrosion, i.e. the desired dissolution of the material, and signs of fatigue of the alloy in an artificial body fluid. In order to simulate the tissue surrounding the bone in the body, they applied a hydrogel to the sample. Their result: although this "tissue layer" does not significantly influence the corrosion rate, it does prevent the precipitation of corrosion products such as oxides and phosphates on the iron surface.

Colleagues from the Chair of Materials Science are working with the team from Technical and Macromolecular Chemistry on the production and analysis of new types of alloys. Implants were produced using powder bed-based selective laser powder bed fusion (LPBF) [6]. In this process, metallic powder is deposited layer by layer in the production system and melted locally by a laser. In this way, the product is built up layer by layer and extremely complex, filigree structures can be realized, some of which are made of new and innovative materials.

The researchers compared samples of pure iron with both an iron-manganese alloy that was rolled and a sample produced using LPBF. The LPBF-produced iron-manganese alloys exhibited the highest corrosion rate [6]. Another focus was on the processes on the surface of the implants. This is because body fluids such as blood plasma, for example, contain proteins that can interact with the surface of the implant. The investigations showed that both the microstructure of the implants and the surrounding proteins have an influence on the degradation rate of the alloys.

Literature

[1] Source: Max Planck Institute for Medical Research

[2] K. Melde; H. Kremer; M Shi; S. Seneca; C. Frey; I. Platzman; C. Degel; D. Schmitt; B. Schölkopf; P. Fischer: Compact Holographic Sound Fields Enable Rapid One-step Assembly of Matter in 3D, Science Advances 9(6) 2023

[3] Source: TH Cologne

[4] Source: University of Paderborn

[5] J. Huang et al: Influence of hydrogel coatings on corrosion and fatigue of iron in simulated body fluid. Materials and Corrosion 73.7 (2022): 1034-1044, (doi.org/10.1002/maco.202112841)

[6] J. Huang et al: Influence of proteins on the corrosion of a conventional and selective laser beam melted FeMn alloy in physiological electrolytes, Corrosion Science 200 (2022): 110186, (doi.org/10.1016/j.corsci.2022.110186)