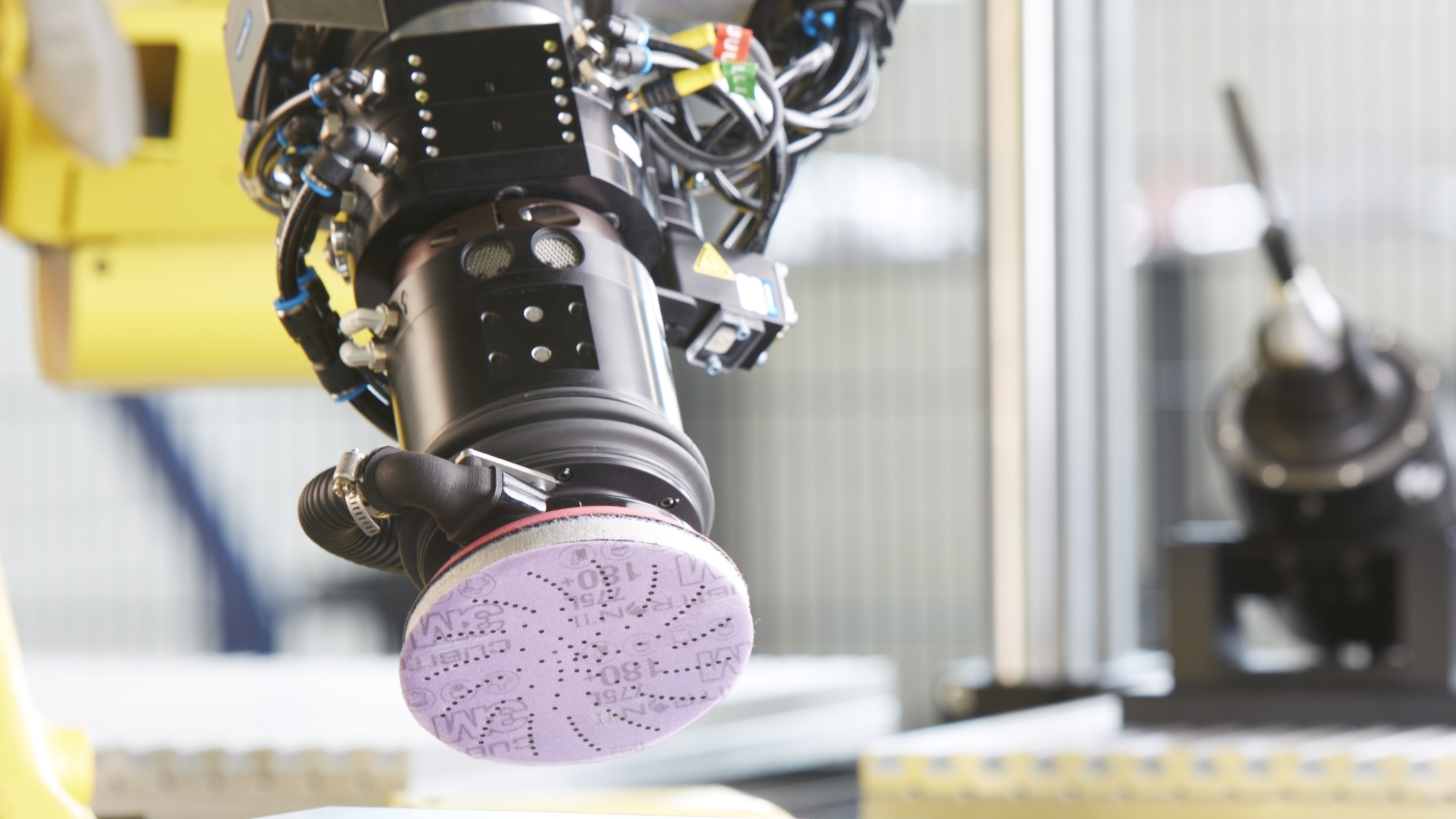

Robot-supported grinding is a demanding task that requires enormous knowledge of techniques, processes and materials. To help users find the optimum solution for their task, two experts in this field have joined forces: SCHUNK, the competence leader for gripping systems and clamping technology, and 3M, one of the leading manufacturers of industrial abrasives. Together they support companies in optimally automating their grinding, polishing and brushing processes.

Grinding, deburring, polishing - when it comes to demanding tasks such as removing material or finishing workpieces, many companies rely on manual processing. However, this is expensive in series production and does not always deliver the desired precision and reproducibility. Robot-supported processes, on the other hand, guarantee consistent quality, unmanned and around the clock. The automation specialist SCHUNK supports customers in application validation through tests in the SCHUNK CoLab and supplies the appropriate components. With the SCHUNK product portfolio for processing with robots, customers will be able to almost completely replace manual grinding, polishing and deburring processes in automated production in the future.

Bundled expertise

In order to open up further potential for users, SCHUNK is now relying on its cooperation with 3M, a leading manufacturer of industrial abrasives. 3M is constantly working on optimizing grinding and polishing processes and making them more efficient with innovative products. Together with SCHUNK's automation expertise, this opens up completely new possibilities for developing optimum grinding, polishing and brushing processes. To this end, both companies combine their expertise and make it available to users through a cooperative sales approach with customer-specific solutions.

When planning an automated sanding application, customers benefit from the experience of both experts. While SCHUNK supplies the right components for the robot and supports the technical implementation of the automation application, 3M finds the right sanding material and the optimum process parameters. For this purpose, quick and simple feasibility studies on various components can be carried out in the SCHUNK CoLab, while 3M's own robotics laboratory offers the opportunity to further optimize the abrasive process and thus achieve optimally coordinated surface results. In this way, customers get the best of both worlds and find the optimum, customized automation solution for their application.