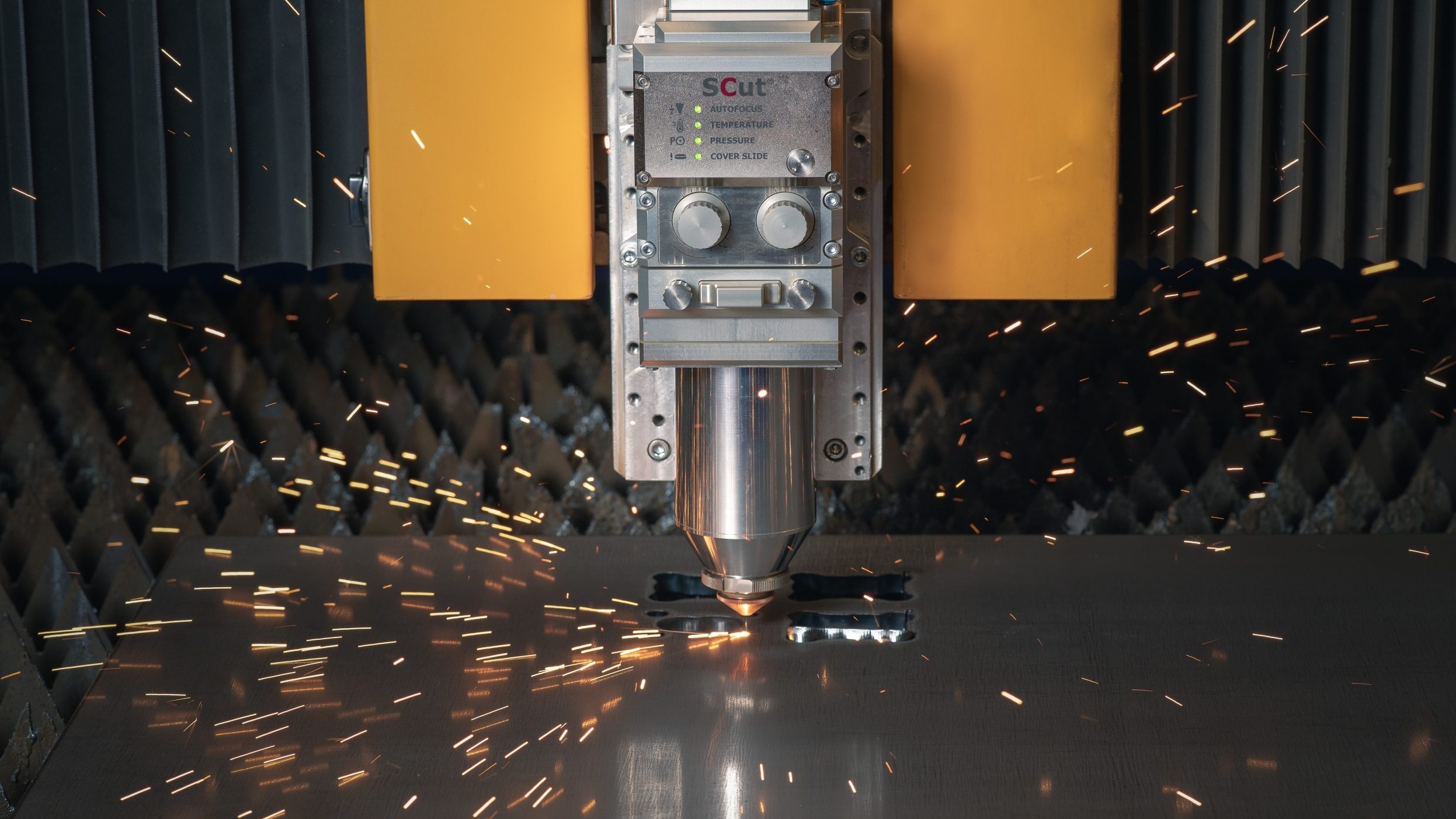

The SCut laser cutting optics ensure burr-free cuts for both flatbed cutting and bevel cutting, for thin sheets as well as thick sheets. To achieve this, SCut combines low-drift distance control with an autofocus function.

The Scansonic developers have rethought the operation of the optics. Horizontal adjustment between the laser beam and nozzle is carried out precisely and true to the axis using two rotary controls on the front. This solution not only saves time during set-up, but also significantly increases the quality of processing.

A sophisticated mechanical sealing system protects the optical components from contamination and ensures that the cutting optics are extremely robust. Continuous seal monitoring notifies the user in good time if the worst comes to the worst.

SCut laser cutting optics are also particularly user-friendly when it comes to maintenance and service. Many maintenance tasks can be carried out by trained personnel on site, and even replacement optics packages can be exchanged. This saves time and avoids system downtime.

The right optics for every task

The portfolio offers the right solution for different requirements: the SCut PRO model is particularly suitable for focusing focal lengths from 125 to 200 mm. The autofocus system covers a wide range, from 20 mm in the direction of the workpiece to 15 mm in the direction of the nozzle. The SCut 360 laser cutting optics are recommended for ring-mode lasers with a large divergence angle. The bundle achieves particularly good results when cutting thicker mild steel with low laser power. The acceptance half-angle of the optics is 360 mrad. This means that the laser cutting optics can also be used for lasers with a larger beam divergence.

Both SCut laser cutting optics work with fiber and disk lasers in the wavelength range from 1030 to 1130 nm and are available with the Optoskand QBH and Trumpf-D fiber connectors. The optics are suitable for all modern and powerful laser cutting systems.

In future, the optics will be sold directly by Scansonic. This offers customers various advantages: Firstly, they benefit from direct manufacturer service. On the other hand, the developers can take up important ideas from users for their work. And last but not least, the shorter distribution channel results in cost benefits that Scansonic passes on to its customers.