The greatest potential of digitalization in material-intensive companies lies in the cross-process linking of material data. It promises to shorten component development times, optimize complex manufacturing processes faster and ensure even more reliable plant operation than before. The problem is the very heterogeneous nature of material data. This makes linking them extremely complex. A research project by the state of Baden-Württemberg led by the Fraunhofer Institute for Mechanics of Materials IWM in Freiburg, MaterialDigital, has now made great progress in structuring material data into a consistent data space.

Not only is the potential of digitalization in materials technology huge, the challenges are also considerable. "Material data is extremely heterogeneous due to its complexity and is constantly changing, even during the product life cycle," says Dr. Christoph Schweizer from the Fraunhofer Institute for Mechanics of Materials IWM, describing the difficulties. "The fact that they vary locally within a product and in some cases cannot be determined non-destructively by measurement makes structuring, storing and linking them so challenging."

The industry therefore faces considerable challenges: How do we get all the data together in a meaningful way? What infrastructure do we need for this? Where do we start with the integration of a data room? Dr. Christoph Schweizer is now providing answers to these questions together with a consortium of seven research institutions that joined forces in the "MaterialDigital" research project in 2018. The Baden-Württemberg Ministry of Economic Affairs, Labor and Housing funded the project with 2.75 million euros.

Pioneering work for the material data room

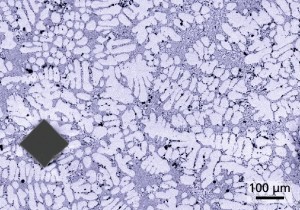

Light microscope image of an aluminum casting structure with the impression of a stamp to determine the so-called Vickers hardness (black diamond). Usingtwo use cases, the partners were able to show how companies can proceed with the digitalization of their material-intensive processes in order to obtain a consistent and machine-readable data space. The use case coordinated by Fraunhofer IWM concerned the gravity die casting of aluminum parts, as used in the automotive and mechanical engineering industries, for example. To this end, they developed the necessary foundations, such as software tools for structuring the data and automating the workflows, and created an exemplary material data space based on this. The partners also proved that digital value chains offer great added value. With the help of real material and process data, the researchers involved were able to use a digital twin to bypass more complex simulations and predict component properties more precisely at the same time.

Light microscope image of an aluminum casting structure with the impression of a stamp to determine the so-called Vickers hardness (black diamond). Usingtwo use cases, the partners were able to show how companies can proceed with the digitalization of their material-intensive processes in order to obtain a consistent and machine-readable data space. The use case coordinated by Fraunhofer IWM concerned the gravity die casting of aluminum parts, as used in the automotive and mechanical engineering industries, for example. To this end, they developed the necessary foundations, such as software tools for structuring the data and automating the workflows, and created an exemplary material data space based on this. The partners also proved that digital value chains offer great added value. With the help of real material and process data, the researchers involved were able to use a digital twin to bypass more complex simulations and predict component properties more precisely at the same time.

"Based on data room queries, fast and precise decisions can be made in material-intensive companies instead of having to go through expensive and time-consuming 'trial & error loops'," says overall project coordinator Dr. Christoph Schweizer. "Our data room architecture is designed in such a way that it can be easily transferred to other material processes." Tools and workflows are therefore available to potentially interested industries to adapt them to their respective needs. The material data structured in the project use case of the aluminum casting process will be published by the consortium as a best-practice example for scientific re-use.

Research potential in decentralization and AI

For Dr Christoph Schweizer, the MaterialDigital state project was immediately followed by an internal Fraunhofer program designed to make the data room technology ready for decentralized use. "Further research potential of the material data room lies in particular in integrable logics and the utilization of machine learning," says the Business Unit Manager for Material Evaluation and Lifetime Concepts. Trained computer models would be able to extract and utilize laws from the process graphs that have not yet been stored. This would allow far more specific statements to be made and the modeling step could be drastically minimized.

Details of the material data space technology

The central concern of the consortium was to develop the technical foundations and workflows for the material data space based on established standard formats. The Fraunhofer IWM in particular was in demand here with its expertise in data handling. "When developing a standardized data structure for material-intensive processes, we practically had to start from scratch because there was virtually no preliminary work," explains Dr. Christoph Schweizer.

The basis of every data room is an ontology, i.e. a common language that ensures that all data can be clearly categorized. In the state project, the participants used ready-made basic ontologies and supplemented the particularly broad specialist vocabulary in materials technology. They then related the data within the data space using a knowledge graph that logically links the data. A well-known example of the use of knowledge graphs are the info boxes that Google presents above the simple links of a search result. If, for example, you are looking for capital cities, the local weather or cinema programs, Google displays suitable images and explanations in a grey box above the actual search results.

App translates process graphs into Excel template

The spatial position of the data can be checked by visualizing the component geometry and individual samples as well as selected cross-scale data sets in the graphical user interface (GUI). © Fraunhofer IWM Withthe help of this basic structure of ontology and knowledge graph, the researchers were initially able to describe individual process steps of the use cases, the so-called "process modeling". In the next step, the individual processes were linked together according to their chronological sequence in the real process chain to form a virtual network. In this final material data space, not only are the process descriptions and their metadata available, but the raw data can also be accessed automatically via links, enabling a variety of evaluations.

The spatial position of the data can be checked by visualizing the component geometry and individual samples as well as selected cross-scale data sets in the graphical user interface (GUI). © Fraunhofer IWM Withthe help of this basic structure of ontology and knowledge graph, the researchers were initially able to describe individual process steps of the use cases, the so-called "process modeling". In the next step, the individual processes were linked together according to their chronological sequence in the real process chain to form a virtual network. In this final material data space, not only are the process descriptions and their metadata available, but the raw data can also be accessed automatically via links, enabling a variety of evaluations.

To enable non-experts to fill the data room with data, the project scientists programmed an app with which the modeled process graphs can be converted fully automatically into an Excel template. This file can be filled manually if required and therefore requires no prior knowledge of data rooms.

Successful improvement in the casting process

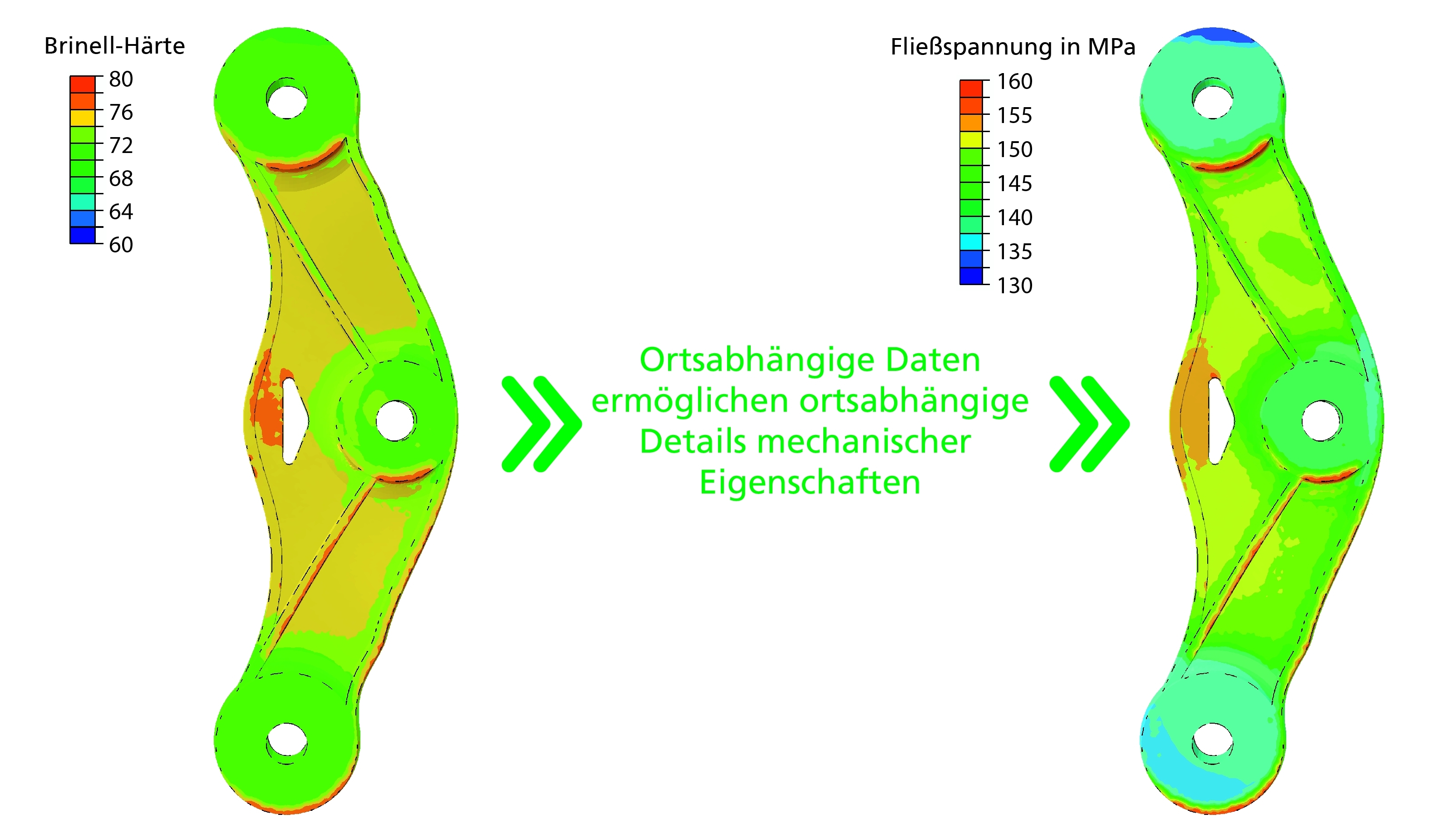

Schweizer and Co proved that this structured and comprehensively linked knowledge base brings real added value by integrating experimental data and simulations. In this way, they created a digital twin for a cast part that utilizes the correlation between the locally varying solidification during casting and the locally varying hardness to create a simulation model with heterogeneously distributed mechanical properties. Using findings from the data room, the simulation model can also be fed with precisely selected material parameters that take into account the casting-specific chemical composition and heat treatment.

Based on the digital twin, the researchers were able to predict the functional mechanical properties of the casting with demonstrably greater precision than with batch-independent material parameters. This was achieved much faster and with less effort than with previous methods.

The final report of the state project MaterialDigital as part of the funding of business-related research projects related to the implementation of the digitization strategy of the Ministry of Economic Affairs, Labour and Housing Baden-Württemberg in the field of digitization: "Opportunity for sustainability and energy transition" can be found under this link.