Although most mobile devices are designed for significantly longer life cycles, these are often not achieved due to their necessary external connection. Corroding charging contacts and connectors for short charging times or fast data transfer make the otherwise intact device suddenly unusable. The resulting complaints from end customers often lead to unforeseen costs on the manufacturer's side, in addition to damage to their image, which in the medium term results in an increased and therefore less attractive product price.

With RHODUNA® Alloy, Umicore Electroplating has created a rhodium-ruthenium electrolyte that addresses precisely this issue. The alloy, which can be applied by means of metal-saving electroplating processes using proven continuous mass production systems, gives contacts unprecedented corrosion resistance - without affecting features such as fast-charging capability.

GOLD-PLATED CONTACTS CAN NO LONGER MEET THE GROWING EXPECTATIONS

The initially rapid development of cell phones, tablets, wireless headphones and smart fitness bracelets is increasingly slowing down. In the meantime, performance, design and handling have often become interchangeable across brands. As a result, even marginal price differences and sustainability are coming into focus. For consumers, the term sustainability does not necessarily go hand in hand with the top 3 ranking in the 2020 Stuttgart Surface Technology Award of the Fraunhofer Institute for Manufacturing Engineering and Automation IPA for Umicore Electroplating 2 / 11 www.ep.umicore.com the environmental concerns often associated with it - rather, it is the expectation of a durable product that can be used at any time without hesitation.

This cannot be achieved with the current standard of gold-plated charging contacts and connectors. Wearables in particular are naturally not used in an environment protected from the outside world and are therefore exposed to galvanic corrosion conditions. During leisure activities in particular, the devices often inevitably come into contact with chloride-containing liquids such as skin sweat, swimming pool or sea water or even drinks. Of course, most devices are at least splash-proof and initially give the impression that they have not been damaged. However, the danger is not in the immediate functionality, but in the medium term on the exposed contacts: in conjunction with chloride-containing solutions, gold-plated contacts inevitably corrode at high speed during the charging process.

CORROSION TEST PROVES THE SUPERIORITY OF THE NEW ALLOY AFTER JUST A FEW MINUTES

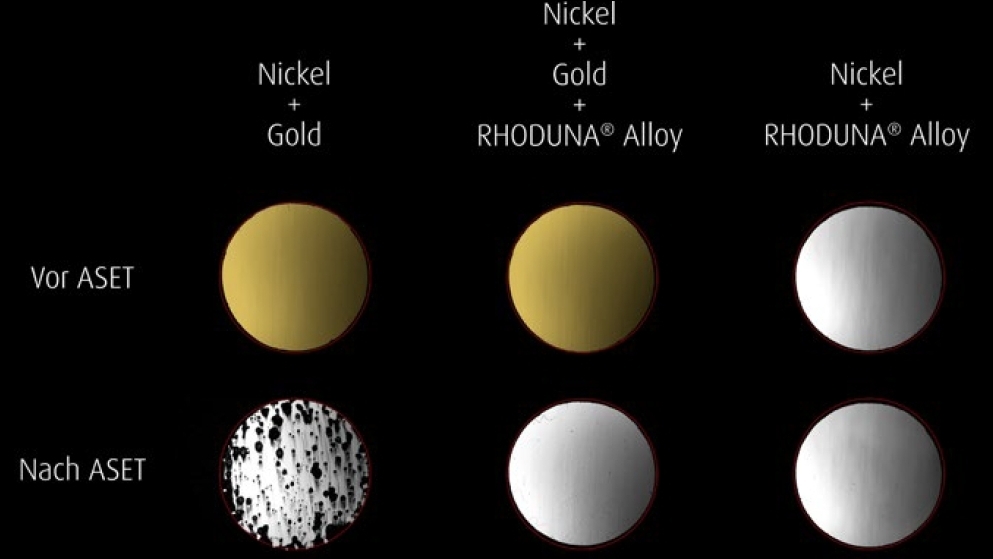

In an electrochemical corrosion test, an approx. one percent saline solution (250ml) is applied to a voltage of 5V at 40°C. This simulates a complete charging cycle in 30 seconds with contacts contaminated with sweat.

After just 2.5 minutes, the 0.75 μm gold layer normally used for contacts has completely dissolved and the nickel substrate is already heavily corroded. In contrast, no corrosion can be seen in the RHODUNA® Alloy alloy under polarized light at 20x magnification. "The chemically almost inert final layer has very low porosity and the overall system therefore has excellent corrosion resistance," says Martin Stegmaier (Head of Decorative Applications), confirming the unprecedented coating characteristics.

SURFACE TECHNOLOGY AWARD 2020 CONFIRMS THE INNOVATIVE CHARACTER OF RHODUNA® ALLOY

With RHODUNA® Alloy, Umicore Electroplating has earned a top position in the Stuttgart Surface Technology Prize, which is awarded every two years by the world-renowned Fraunhofer Institute for Manufacturing Engineering and Automation IPA. Its head of department for electroplating technology, Dr. Martin Metzner, explains the 3rd place with a simple fact: "Umicore ... has succeeded ... in countering the complex and often adverse influences to which the contacts of mobile devices are exposed". Uwe Manz (Head of Research & Development) is particularly pleased with the award for one reason: "Of course, our commercial success shows that we are developing the right products for the various markets. But the award also confirms that we are still at the forefront in terms of innovation, sustainability, enabler qualities and industrial feasibility - the criteria according to which the prize was awarded."

SUSTAINABILITY BRINGS ECONOMIC EFFICIENCY

RHODUNA® Alloy is a win-win situation for everyone involved. The user enjoys a longer service life and therefore sustainability for their mobile device. The manufacturer benefits in two ways: on the one hand, the additional product reliability contributes directly to the manufacturer's image. Secondly, RHODUNA ® Alloy makes the overall costing significantly more economical - despite the four times higher investment for the alloy compared to the gold coating.

While it is difficult to measure the image gain and the resulting supposedly higher sales volume only has an effect in the medium term, the savings on complaints due to corroded contacts can be clearly and immediately quantified. Costs for correspondence, logistics and, of course, for the repair or replacement of defective devices are eliminated without replacement.

HIGH QUALITY ALSO IN TECHNICAL SALES PROVIDES A COMPREHENSIVE BASIS FOR DECISION-MAKING

Umicore's sales team allays any fears of converting a functioning process during the first meeting by presenting the onboarding roadmap. Before any possible introduction or changeover to RHODUNA® Alloy, an unusually detailed survey of the existing process environment is carried out, which, according to Umicore, ensures a smooth go-live and thus, in the worst case, no production downtimes.

But the company's non-binding service does not end there. "We are aware that the prospective customer needs a comprehensive basis for decision-making that goes far beyond an individual price calculation, product samples and, if necessary, optimization tips for an optimal process landscape. That's why we also include test production in the customer's environment," says Markus Legeler (Head of International Sales), describing onboarding for customers, adding: "Of course, due to the current circumstances, we can map all steps from consulting, setup and employee training to ongoing production support completely virtually on request."