Whether in industry, trade, commerce, agriculture, medical facilities or municipal buildings: outdated pump systems are real energy guzzlers. Modern pumps not only work more energy-efficiently, they also offer operators another essential advantage: they guarantee operational reliability. With modern pump systems, there is no longer any need to factor in susceptibility to faults and the associated production stoppages. pesContracting, the Bavarian specialist service provider for pump replacement, knows what risks outdated pump systems pose for companies and the public sector and how retrofitting can significantly increase operational reliability.

Especially in industry, heating, cooling water and booster pumps are in use around the clock. Once the pump system is getting on in years, wear-related faults can accumulate. "Old pump systems not only consume considerably more energy, but are also more susceptible to faults. The maintenance of these pumps can quickly become expensive", explains Michael Buchta, Sales Manager at pesContracting, "in the worst case, there is even a risk of complete failure". For smaller companies, this can even threaten their existence. "It happens time and again that spare parts are very difficult to obtain and delivery times of up to four weeks are not uncommon. Bridging this downtime is a financial challenge for companies," explains Buchta. To prevent this from happening in the first place, pesContracting offers a free inventory analysis. This involves checking the current pump inventory and calculating possible optimization and savings potential.

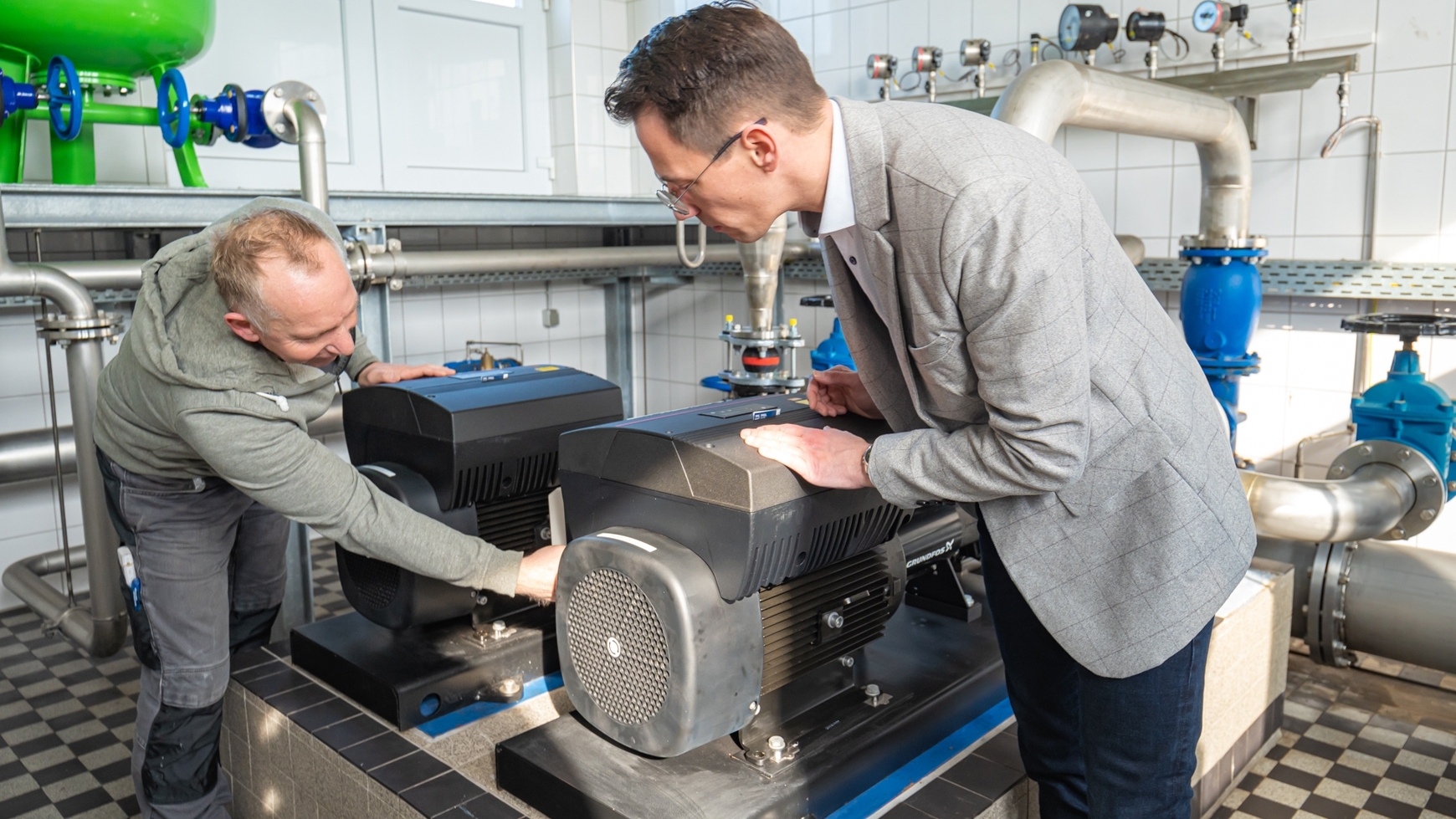

Cost savings and greater operational reliability

To save costs, companies often maintain their pump systems themselves. This can sometimes be expensive if a lack of specialist knowledge leads to avoidable damage, as Michael Buchta knows: "An analysis of an industrial customer's pump system revealed major damage due to incorrect use. The new price of the system is around 22,000 euros. Replacing older pumps would have been considerably cheaper," says Buchta. To avoid scenarios like this, operators should have the status of their pumps checked regularly and consider replacing outdated models. Modern pump technology makes it possible to detect faults in real time and thus avoid breakdowns.

Investment-free and liquidity-saving pump replacement

The advantages of replacing pumps are obvious, especially the increased operational reliability with lower operating costs. Nevertheless, companies shy away from retrofitting their old pumps. The reason is often the high investment costs. The investment-free and cash-saving pump replacement with pesContracting shows that there is another way: the project costs are based on the demonstrable reduction in consumption, so that no investment is required on the part of the customer. Instead, they benefit from smart, energy-efficient technology and maximum operational reliability, protect the company's liquidity and gain important financial leeway for their core business. The reduced energy consumption not only has added value for the company, but also for the environment: the electricity savings lead to lowerCO2 emissions and therefore more climate protection.