Together with researchers from Ulm and Neuchâtel, the Swiss Federal Laboratories for Materials Science and Technology Empa will soon be examining material samples on the International Space Station ISS. The samples are super-hard and corrosion-resistant alloys of palladium, nickel, copper and phosphorus - also known as "metallic glasses".

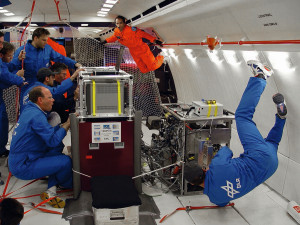

Weightless for seconds: Scientists from the University of Ulm during a melting test in the Zero-G Airbus from Novespace (Photo: Airbus Defence and Space)It has the color of white gold, but it is as hard as quartz glass and at the same time has a high degree of elasticity. The smooth and grain-free surface makes the material resistant to salts and acids. Individual pieces - for medical implants, for example - can be produced using 3D printing, while larger series - for watch cases, for example - are manufactured using injection molding. This is roughly how the material of dreams that scientists are currently researching is described. We are talking about "metallic glass".

Weightless for seconds: Scientists from the University of Ulm during a melting test in the Zero-G Airbus from Novespace (Photo: Airbus Defence and Space)It has the color of white gold, but it is as hard as quartz glass and at the same time has a high degree of elasticity. The smooth and grain-free surface makes the material resistant to salts and acids. Individual pieces - for medical implants, for example - can be produced using 3D printing, while larger series - for watch cases, for example - are manufactured using injection molding. This is roughly how the material of dreams that scientists are currently researching is described. We are talking about "metallic glass".

At Empa, Antonia Neels, Head of the Empa X-ray Center, has been working on this mysterious material for around 15 years. Her team investigates the inner structure of metallic glass using various X-ray methods and discovers correlations with properties such as deformability or fracture behavior. Metallic glass is a tough nut to crack, even for materials science experts: "The closer we look at the samples, the more questions arise," says Antonia Neels. This spurs on the researchers' ambition all the more.

Into space together

In a few months' time, a sample of metallic glass will be examined in the weightlessness of the International Space Station (ISS). A research group involving Empa has prepared the samples and registered them with the European Space Agency ESA for the space flight. The special alloy is supplied by the PX Group from La Chaux-de-Fonds, which manufactures materials for the watch industry and dental technology. The team also includes researchers Markus Mohr and Hans-Jörg Fecht from the Institute of Functional Nanosystems at the University of Ulm and Roland Logé from the Laboratory of Thermomechanical Metallurgy at EPFL in Neuchâtel.

The production of metallic glass is not easy: compared to window glass, the specially selected metal alloys have to be cooled up to a hundred times faster so that the metal atoms do not form crystal lattices. Only when the molten metal solidifies like a shock does it form a glass.

In industry, thin films of metallic glass are produced by pressing the molten metal between rapidly rotating copper rollers. Researchers sometimes cast their samples in molds made of solid copper, which dissipates heat particularly well. However, larger, solid workpieces made of metallic glass cannot be produced using these methods.

3D printing can help

One possible way out of the dilemma is 3D printing using the powder bed process. A fine powder of the desired alloy is heated with a laser for a few milliseconds. The metal grains fuse with their neighbors to form a kind of foil. A thin layer of powder is then placed on top, the laser fuses the freshly applied powder with the foil underneath, and a three-dimensional workpiece is gradually created from many briefly heated powder grains. This method requires fine dosing of the laser pulse. If the laser burns too weakly on the powder, the particles do not fuse together and the workpiece remains porous. If the laser burns too strongly, it also melts the lower layers again. The repeated melting allows the atoms to rearrange themselves, forming crystals - and that's the end of metallic glass.

X-ray methods and their extraordinary diversity

Empa researcher Antonia Neels heads the Center for X-ray Analysis. She is an expert in metallic glasses and will analyze the samples from the ISSAtEmpa's X-ray Center, Antonia Neels' team has already analyzed several such samples from 3D printing experiments. However, the results always raise new questions. "There are some indications that the mechanical properties of the glass do not deteriorate, but on the contrary even improve, if the sample contains small crystalline components," says Neels. "We are now investigating the question of how large this crystal content must be in the glass and what type of crystals must form in order to increase the flexibility or impact strength of the glass at room temperature, for example."

Empa researcher Antonia Neels heads the Center for X-ray Analysis. She is an expert in metallic glasses and will analyze the samples from the ISSAtEmpa's X-ray Center, Antonia Neels' team has already analyzed several such samples from 3D printing experiments. However, the results always raise new questions. "There are some indications that the mechanical properties of the glass do not deteriorate, but on the contrary even improve, if the sample contains small crystalline components," says Neels. "We are now investigating the question of how large this crystal content must be in the glass and what type of crystals must form in order to increase the flexibility or impact strength of the glass at room temperature, for example."

In order to track down crystal growth in an otherwise amorphous environment, the experts at Empa use various X-ray methods. "With radiation of different wavelengths, we can find out something about the structure of the crystalline components, but also determine close-order phenomena of the atoms in the sample - in other words, determine the properties of the chemical bonds," explains Neels. In addition, the imaging X-ray analysis, known as microCT, reveals something about density fluctuations in the sample. This indicates phase segregation and crystal formation. However, the differences in density between the glassy and crystalline areas are only minute. Detailed image processing is therefore required to make the three-dimensional distribution of the crystalline components visible.

Parabolic flight in the Airbus

However, material samples from the 3D laser printer alone cannot fully solve the mystery of the metallic glasses. "We need to know at what temperatures these crystals form and how they grow in order to define stable manufacturing processes," explains X-ray specialist Neels. Important information is provided by thermo-physical parameters of the melt, such as viscosity and surface tension. Experiments on the ISS provide ideal conditions for these analyses. Preliminary experiments take place in parabolic flights.

The first droplets of metallic glass floated on a trial basis back in 2019. A specially converted Airbus A310 from Novespace flew a zero-gravity flight with a material sample. On board were scientists from Ulm and a small, metallic glass droplet from the PX Group in La Chaux-de-Fonds. The metallic glass that the research group is investigating consists of palladium, copper, nickel and phosphorus. In the experiment called TEMPUS (crucible-free electromagnetic processing under zero gravity), the glass droplets were kept in suspension by means of a magnetic field and heated up to 1500 degrees Celsius by induction. During the cooling phase, two short induction current pulses caused the glowing droplet to vibrate. A camera recorded the experiment. After landing, the material sample was analyzed at Empa's X-ray center.

Why the ISS delivers more results

The evaluation of the video from the parabolic flight allows conclusions to be drawn about the viscosity and surface tension of the droplet - important data for better controlling the production of metallic glasses with certain properties. However, the period of weightlessness during the flight only lasts 20 seconds - too little for a detailed analysis. This is only possible on the ISS.

A sample of the same material has now been registered for a flight in the European Columbus module of the ISS. The ISS-EML electromagnetic levitation furnace has been installed there since 2014. In each case, 18 material samples fly along, are automatically rotated and can be observed by researchers on Earth via video stream. The metallic glass from Switzerland will travel into space with the next batch of samples.

Computer simulation for new casting processes

The researchers want to use the far more detailed data from the space flight to generate a computer simulation of the melt. This will bring together all the answers from a combination of experiments on Earth and in space in a standardized model: At what temperature does what viscosity and surface tension prevail? When do crystals of which composition, size and orientation form? How does this internal material structure influence the properties of the metallic glass? Together with industrial partner PX Group, the researchers want to use all these parameters to develop a manufacturing method to produce the coveted material in a defined form. In the next few years, there is still a lot to do for the materials researchers in all the teams involved.