Glass windows have always characterized apartments and houses and let light into buildings. As developments by the Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP in Dresden together with partners show, smart windows can regulate the heat input of solar radiation according to the weather situation by means of special coatings - and thus presumably achieve significant energy savings.

Among other things, the scientists succeeded in producing the world's first thermochromic coating on ultra-thin glass using a roll-to-roll process. Results that could make mechanical blinds superfluous in future and at the same time reduce a building's cooling and heating energy requirements. The article presents the various technological developments.

Window efficiency has been optimized since the 1970s

Within the European Union, the building sector currently accounts for around 40 % of primary energy consumption [1]. Against this background, numerous initiatives have been launched to improve this balance. These include the EU Switch2Save project, which involves the development of energy-saving renovation solutions for windows and the results of which are the main focus of this article.

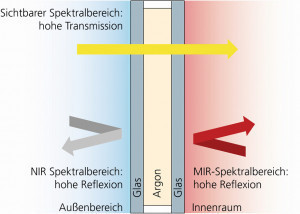

Fig. 1: (Left) typical effect of the integration of low-e and solar control layer systems in IGUs, (right) typical layer structures for solar control and low-e systems (all graphics: Fraunhofer FEP)

Office complexes, public buildings and new buildings are usually architecturally characterized by large, south-facing windows and glass facades. The energy exchange between the interior of the building and the environment is strongly influenced by the windows and is of decisive importance for the energy balance. Since the first oil crisis in the 1970s, efforts have been intensified to design and control this energy flow for improved efficiency. Milestones on this path were the integrated glass unit (IGU) and the low-e and solar control coatings (Fig. 1). These consist of several layers of thin coatings which, when combined, mean that the panes remain transparent to visible light, but act like a mirror in the infrared (IR) spectral range.

This influences both the heat radiation that cools the interior of the building in winter (mid infrared range - MIR) and the spectral range of sunlight that leads to undesirable heating of the building in the case of strong irradiation, especially in the summer months (near infrared range - NIR). With such solutions, optimization can be achieved for a specific location with typical weather conditions or for a specific season.

... the Nikaia Hospital in Athens. Both buildings will be used to demonstrate and evaluate the potential of smart coatingsFora further improvement in the energy balance, it is desirable to have glazing with variable optical properties. This is because while solar radiation is used to support heating in winter, the inside of the building heats up in summer and requires active cooling. Common shading systems include solar shading slats and blinds. However, these reduce comfort and only make a limited contribution to utilizing the heat input into the building in winter. To counteract these disadvantages, it is necessary for window or glass façades to be able to meet conflicting requirements: on the one hand, there should be an undisturbed view to the outside, while on the other hand, the lowest possible total energy transmittance (g value) is desired.

... the Nikaia Hospital in Athens. Both buildings will be used to demonstrate and evaluate the potential of smart coatingsFora further improvement in the energy balance, it is desirable to have glazing with variable optical properties. This is because while solar radiation is used to support heating in winter, the inside of the building heats up in summer and requires active cooling. Common shading systems include solar shading slats and blinds. However, these reduce comfort and only make a limited contribution to utilizing the heat input into the building in winter. To counteract these disadvantages, it is necessary for window or glass façades to be able to meet conflicting requirements: on the one hand, there should be an undisturbed view to the outside, while on the other hand, the lowest possible total energy transmittance (g value) is desired.

It is possible to switch the g-value depending on the time of day and season, for example, by using a variety of intrinsic material properties such as photochromic and thermochromic (TC) materials. Such materials change their transparency - and thus their g-value - when a certain temperature or light irradiation is reached. Active g-value switching is possible, for example, using electrochromic (EC) systems by changing the applied voltage. The use of these systems allows the visual connection to the outside to be maintained in both clear and tinted states.

Electrochromics

Electrochromic materials and elements change their transmission and/or reflection properties when an electrical voltage or current is applied. This phenomenon can be used, for example, to control light and thus shade/darken windows. There are a variety of inorganic, organic and hybrid materials that are applied as thin layers to transparent, conductive glass and film substrates using physical and chemical coating methods. The main known classes of materials are metal oxides, metal complexes, viologens, conjugated and supramolecular polymers [3]. In commercially available electrochromic glazing, tungsten oxide and nickel oxide are mainly used as coloring materials. Doped metal oxides, such as ITO (tin-doped indium oxide) or FTO (fluorine-doped tin oxide), but also metal structures, graphenes or conductive polymer layers are frequently used for the transparent, conductive layers. However, ITO or FTO still have the most favorable property profile (high transmission and high conductivity) for use in electrochromic windows. The switching of electrochromic materials is based on redox processes, whereby a reversible charge and ion exchange takes place, which ensures the decoloration or coloration of the layers [4].

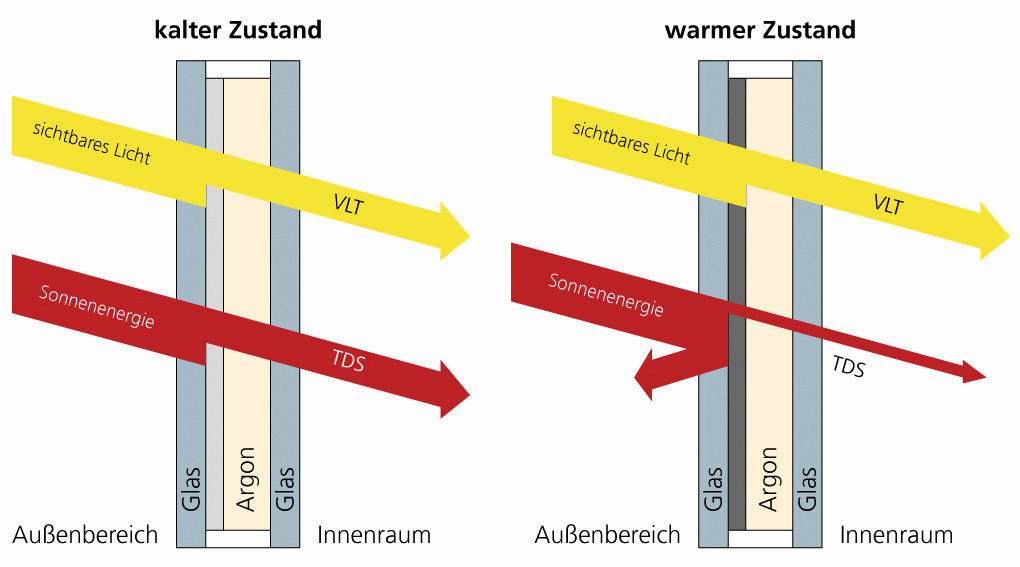

![Abb. 2: Wirkung einer elektrochromen Verglasung im klaren und getönten Zustand (VLT: Visible Light Transmission; TDS: Direct Solar Transmission) in Anlehnung an Ref. [M. Casini, Actice dynamic windows for buildings: A review, Renewable Energy 2018, 119, 923-934] erstellt Abb. 2: Wirkung einer elektrochromen Verglasung im klaren und getönten Zustand (VLT: Visible Light Transmission; TDS: Direct Solar Transmission) in Anlehnung an Ref. [M. Casini, Actice dynamic windows for buildings: A review, Renewable Energy 2018, 119, 923-934] erstellt](/images/stories/Abo-2023-02/gt-2023-02-048.jpg) Fig. 2: Effect of electrochromic glazing in the clear and tinted state (VLT: Visible Light Transmission; TDS: Direct Solar Transmission) based on Ref. Casini, Actice dynamic windows for buildings: A review, Renewable Energy 2018, 119, 923-934].

Fig. 2: Effect of electrochromic glazing in the clear and tinted state (VLT: Visible Light Transmission; TDS: Direct Solar Transmission) based on Ref. Casini, Actice dynamic windows for buildings: A review, Renewable Energy 2018, 119, 923-934].

Figure 2 shows the effect of electrochromic glazing on the radiant energy and the visible spectrum of incident sunlight.

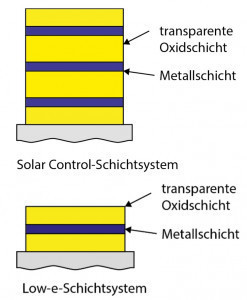

Fig. 3: (Left) Structure of an electrochromic cell and (right) implementation in a window

Fig. 3: (Left) Structure of an electrochromic cell and (right) implementation in a window

Figure 3 shows the basic structure of an electrochromic element and its application in a window according to the concept of the Switch2Save project.

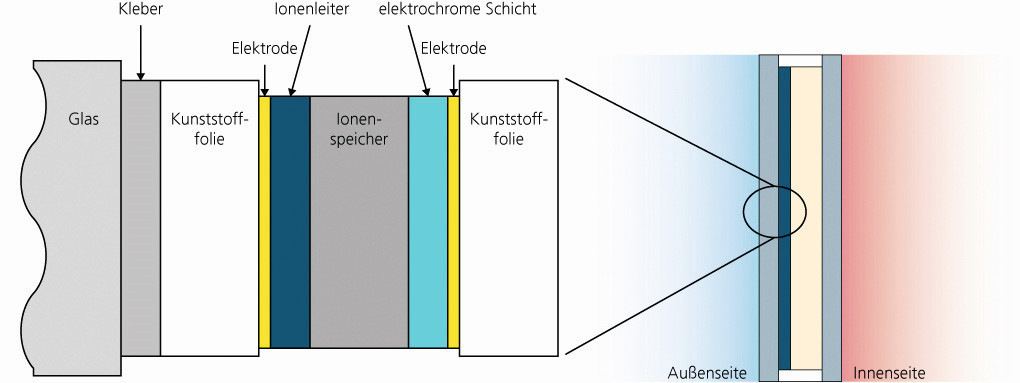

Fig. 4: Transmission spectra of an electrochromic cell in the light and dark stateThehalf-cell components (electrodes) consist of the plastic substrate, the conductive layer and an electrochromic layer (half-cell 1) or a complementary coloring electrochromic layer or ion storage layer (ISL; ion storage layer) (half-cell 2). A highly transparent and ion-conducting electrolyte, which connects the two half-cells (substrate/conductive layer/EC or ISL), is another important component of a functional electrochromic cell (Fig. 3). The electrochromic cell is generally sealed from the outside by an edge seal, primarily to protect the electrolyte from moisture. The contacting of the conductive layers ensures that the electrochromic cell is controlled via an external control unit, which can also be automated depending on the application. Electrochromic (dimmable) glazing works by alternately brightening and darkening the electrochromic cell, which allows the amount of light and heat entering the building to be regulated (Fig. 2). In principle, it is also possible to set intermediate states.

Fig. 4: Transmission spectra of an electrochromic cell in the light and dark stateThehalf-cell components (electrodes) consist of the plastic substrate, the conductive layer and an electrochromic layer (half-cell 1) or a complementary coloring electrochromic layer or ion storage layer (ISL; ion storage layer) (half-cell 2). A highly transparent and ion-conducting electrolyte, which connects the two half-cells (substrate/conductive layer/EC or ISL), is another important component of a functional electrochromic cell (Fig. 3). The electrochromic cell is generally sealed from the outside by an edge seal, primarily to protect the electrolyte from moisture. The contacting of the conductive layers ensures that the electrochromic cell is controlled via an external control unit, which can also be automated depending on the application. Electrochromic (dimmable) glazing works by alternately brightening and darkening the electrochromic cell, which allows the amount of light and heat entering the building to be regulated (Fig. 2). In principle, it is also possible to set intermediate states.

Within Switch2Save, two partners, the Fraunhofer Institute for Silicate Research ISC and the Swedish company ChromoGenics, have combined their technologies. As a result, optimized transmission properties have been achieved.

Electrochromic elements are particularly interesting for applications in the architectural, automotive and transportation sectors and offer many advantages such as glare protection, control of lighting conditions and interior temperature as well as energy savings for air conditioning [5].

The EU Switch2Save project is investigating both electrochromic (Fig. 4) and thermochromic systems as well as the combination of both systems with regard to energy-efficient glass façades.

Thermochromic

Visual impression of an electrochromic window from ChromoGenics Thermochromic coatings enable another type of window with variable optical properties. In this case, the change in optical properties occurs in response to a change in the temperature of the window or of a pane installed in the window. This principle has the great advantage that it simplifies installation considerably. No electrical installations are necessary. This is particularly advantageous for retrofit solutions as part of renovations. On the other hand, this feature is also associated with a decisive disadvantage. Once installed, thermochromic panes are beyond human control. This means that their properties must be precisely matched to the respective application so that the windows can actually achieve the desired energy savings. Ultimately, a kind of "property on demand" approach is required. This is especially true if you have a wide range of applications in different climate zones in mind.

Visual impression of an electrochromic window from ChromoGenics Thermochromic coatings enable another type of window with variable optical properties. In this case, the change in optical properties occurs in response to a change in the temperature of the window or of a pane installed in the window. This principle has the great advantage that it simplifies installation considerably. No electrical installations are necessary. This is particularly advantageous for retrofit solutions as part of renovations. On the other hand, this feature is also associated with a decisive disadvantage. Once installed, thermochromic panes are beyond human control. This means that their properties must be precisely matched to the respective application so that the windows can actually achieve the desired energy savings. Ultimately, a kind of "property on demand" approach is required. This is especially true if you have a wide range of applications in different climate zones in mind.

There are different classes of thermochromic materials. The best-researched compound, and the only one that will be discussed in this article, is vanadium dioxide [6]. This substance exhibits a structural phase transition in which the high-temperature tetragonal phase changes into a low-temperature monoclinic crystal structure. This takes place at 63 °C, although this temperature can be shifted to lower values by doping. This transition is associated with a change in the optical properties.

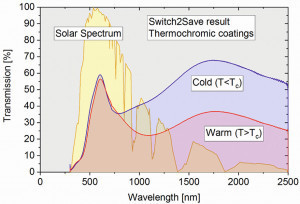

What is striking and fundamentally different from the previously considered electrochromic layers is that this change only takes place in the infrared spectral range, meaning that it remains almost unnoticeable to the human eye. In the low-temperature phase, vanadium dioxide behaves similarly to many other transparent oxides. It largely allows sunlight to pass through, although it does exhibit a certain degree of absorption in the visible spectral range, which leads to a yellowish coloration. In the high-temperature phase, however, it exhibits properties typical of metals. Free electrons then exist in the material, which not only lead to electrical conductivity, but also increase the reflectivity of the layer in the infrared spectral range. The effect of the thermochromic layer can be seen in Figure 5.

In the low-temperature phase, the visible and infrared radiation of the incident sunlight are both slightly attenuated. In the high-temperature phase, the attenuation of the infrared radiation is significantly increased, which is almost exclusively due to increased reflection. In the visible spectral range, however, the properties remain unchanged.

Fig. 5: Effect of a thermochromic window in the cold and warm state

Fig. 5: Effect of a thermochromic window in the cold and warm state

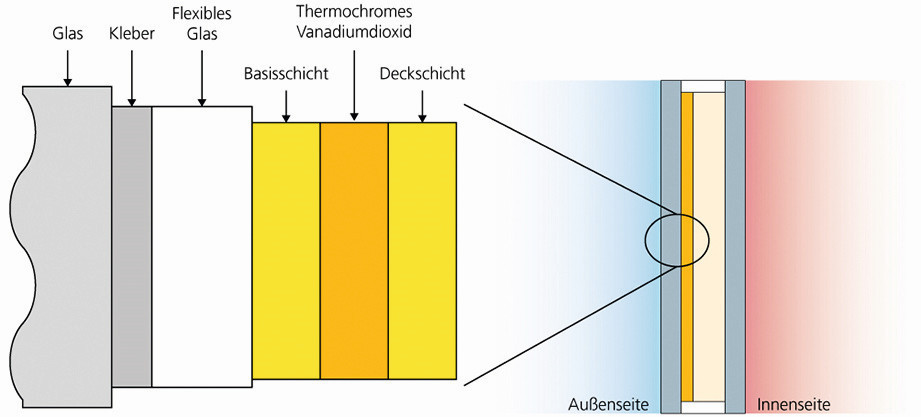

Many efforts have been made to optimize the behavior of thermochromic vanadium dioxide. One of the most important is the embedding in two other oxide layers, resulting in a structure as shown in Figure 6.

Fig. 6: (Left) Structure of a thermochromic cell and (right) implementation in a window

Fig. 6: (Left) Structure of a thermochromic cell and (right) implementation in a window

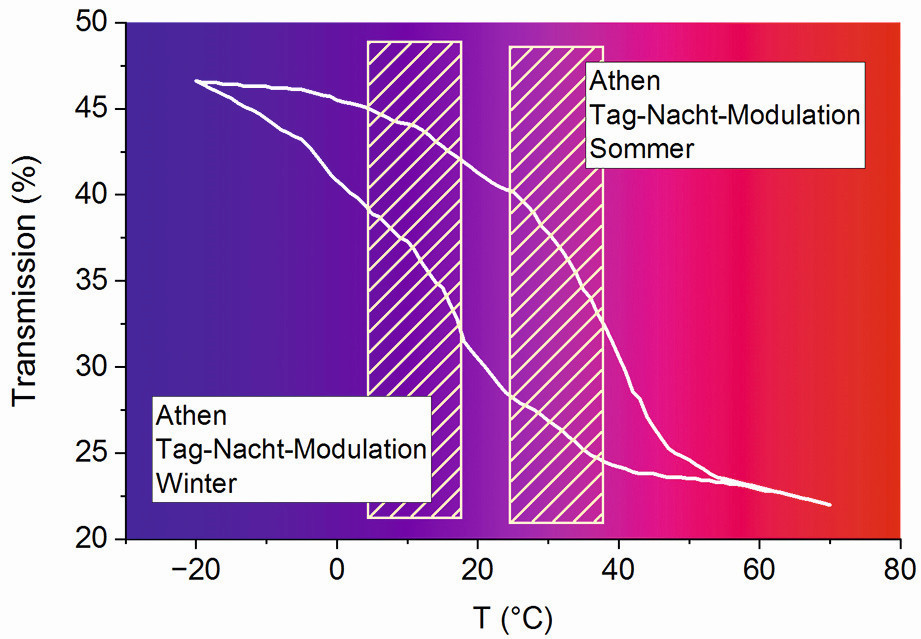

This can improve the properties of the active material. Furthermore, the embedding causes an increase in light transmission, which is generally important for architectural applications. The same applies to the adjustment of the transition temperature. The value of 68 °C is too high to achieve positive effects for the energy balance. The necessary reduction is achieved by doping the layer with atoms of other elements, such as tungsten. For thin films, the transition is not abrupt, but extends over a temperature range of several tens of Kelvin. In addition, a hysteresis can be seen, i.e. a change in the effect that occurs with a delay compared to a change in the cause (Fig. 7).

Fig. 7: Hysteresis of a thermochromic layer. The marked areas indicate the day-night modulation using the example of Athens. It is clear that a special adaptation to the climate of the place of use is necessary for the coatings

Fig. 7: Hysteresis of a thermochromic layer. The marked areas indicate the day-night modulation using the example of Athens. It is clear that a special adaptation to the climate of the place of use is necessary for the coatings

The exact shape of the curve in Figure 7 depends on many factors. In addition to the parameters already mentioned, the coating thickness itself, the purity of the thermochromic structure or the coating tension also have an influence on the behavior. Understanding these relationships is the current subject of research in terms of the initially formulated claim of "property on demand" production.

The expertise of two partners was also combined for the thermochromic layers, in this case the Fraunhofer FEP and the University of West Bohemia in Pilsen. The jointly achieved result [7] can be seen in Figure 8.

Integration into buildings

Fig. 8: Graphic representation of the spectrum of a TC glass in cold and warm statesWithinthe Switch2Save project, not only were the layers shown further developed and integrated into window components, but their effect in real buildings was also to be demonstrated. The focus here is primarily on electrochromism and its combination with thermochromism.

Fig. 8: Graphic representation of the spectrum of a TC glass in cold and warm statesWithinthe Switch2Save project, not only were the layers shown further developed and integrated into window components, but their effect in real buildings was also to be demonstrated. The focus here is primarily on electrochromism and its combination with thermochromism.

The test started with a simulation of the maximum possible energy saving. The climatic data of two fundamentally different locations in Europe were selected for this purpose: Stockholm as an example of an installation in northern Europe and Athens as the corresponding counterpart in southern Europe. A maximum possible saving in the double-digit percentage range was calculated. The exact value depends heavily on the WWR (window-to-wall ratio). It should be noted that the lower proportion of artificial lighting has a significant influence on the energy balance of the building. Two existing buildings were selected for the real test (cover picture and Fig. page 151). In both buildings, conventional windows are currently being replaced by modernized ones. These modernized windows contain an electrochromic functionality that is combined with conventional low-e layers in an assembly-ready unit (IGU).

This change is accompanied by extensive measurements. The effect of the coatings will be monitored over a period of at least one year. The focus is not only on measured values that are relevant for the pure energy balance, but also on parameters that are important for the well-being of the people who spend time in the rooms under investigation. These include, for example, air humidity, temperature gradients within the room, air movement and information on lighting. A special sensor was developed as part of the Switch2Save project to record all the relevant variables.

In addition to the tests in the two demonstration buildings, special laboratory buildings were set up at the University of Athens to test the effect of building components under defined conditions. A similar approach was also adopted for testing the thermochromic layers. Based on the properties determined in the project, the implementation of such layers in transparent roofs was identified as a promising application scenario. A test stand is also being set up for this purpose, which the researchers intend to use to obtain data that can be used to further develop the technology.

Summary and outlook

Visual comparison between a thermochromic coating (center) and uncoated glass The ever-increasing demands on the energy efficiency of buildings make it necessary to equip windows with variable optical properties. As part of the Horizon 2020 Switch2Save project, two different types of such adaptable glass panes were optimized and tested. Electrochromic layers can be controlled and automated by humans, while thermochromic layers react to the ambient temperature. For the optimal installation of windows with such intelligent layers, model calculations predicted a savings potential in the double-digit percentage range. The focus of the project was on lightweight, retrofittable solutions. These are currently being installed in two demonstration buildings, one in Sweden and another in Greece. The effects are being comprehensively monitored. In addition to the energy-related parameters, attention is also being paid to the well-being of the people in the rooms. The researchers hope to be able to present enough data at the end of the project to initiate widespread use.

Visual comparison between a thermochromic coating (center) and uncoated glass The ever-increasing demands on the energy efficiency of buildings make it necessary to equip windows with variable optical properties. As part of the Horizon 2020 Switch2Save project, two different types of such adaptable glass panes were optimized and tested. Electrochromic layers can be controlled and automated by humans, while thermochromic layers react to the ambient temperature. For the optimal installation of windows with such intelligent layers, model calculations predicted a savings potential in the double-digit percentage range. The focus of the project was on lightweight, retrofittable solutions. These are currently being installed in two demonstration buildings, one in Sweden and another in Greece. The effects are being comprehensively monitored. In addition to the energy-related parameters, attention is also being paid to the well-being of the people in the rooms. The researchers hope to be able to present enough data at the end of the project to initiate widespread use.

INFO

Switch2Save project

Lightweight switchable smart solutions for

energy saving large windows and glass facades

Project duration: 1.10.2019 - 30.9.2023

This project has received funding from the European Union's Horizon 2020 research and innovation program under grant agreement No 869929 for the Switch2Save project.

Literature

[1] https://www.irbnet.de/daten/iconda/CIB_DC26383.pdf

[2] https://switch2save.eu

[3] Electrochromic Materials and Devices: Wiley-VCH (Book), 2015, https://onlinelibrary.wiley.com/doi/book/10.1002/9783527679850

[4] Advanced Materials Technologies (2021), 6, 2000836, https://doi.org/10.1002/admt.202000836

[5] Energies (2020), 13, 1449 (Review) https://doi.org/10.3390/en13061449

[6] X. Wang; S. Narayan: Thermochromic Materials for Smart Windows: A State-of-Art Review, Front. Energy Res., 8 December 2021, https://doi.org/10.3389/fenrg.2021.800382

[7] Surface and Coatings Technology, Volume 442, July 25, 2022, 128273