Easier creation of boundary-scan projects

XJTAG releases the new version 3.13 of JTAG boundary-scan tools. This version introduces an efficient method for dealing with build variants, i.e. assembled boards that share a common PCB layout but have component differences.

The version has the following new features, among others:

- An algorithm recognizes I2C components. Basic tests for this are created automatically.

- The handling of power and earthing networks during test project creation is simplified.

- Images can be added to message fields and dialogs, which are displayed to the operator.

For example, it is now possible to create a single baseline project and then define how each variant differs from this baseline. After importing BOM files for each variant, a wizard compares the baseline BOM with the imported one and makes suggestions on how to adjust the boundary scan test.

The new algorithm recognizes I2C interfaces so that all basic tests are then carried out automatically. Base tests for I2C components are also created automatically if none are available in the library.

Various algorithms are used to identify power and earthing networks. The results are summarized in a single list with the new version. Each identified network is given a score to determine the probability that it is a power or earth network. Information about XJTAG will be presented at the Göpel stand -dir/vk-

Hall 4a Stand 222

DMS for machine suppliers and end customers

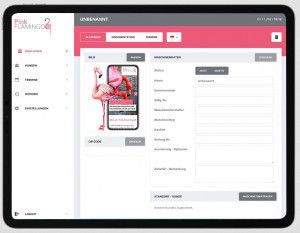

Image: Butter and Salt tech marketingThetechnical marketing agency Butter and Salt worked together with a machine manufacturer to think about how service could be made more efficient and customer-friendly. The result is a system called Pink Flamingo, the basic version of which is a document management system in which, for example, machine master data, maintenance manuals, operating instructions or maintenance logs are stored digitally for each machine. All machines sold by a machine supplier can be supplied with an individual QR code. This leads to a web-based database in which all documents for each machine are stored and maintained by the manufacturer or supplier. Authorized machine operators can access these documents by scanning the code, explains Managing Director Florian Schildein in an interview with PLUS.

Image: Butter and Salt tech marketingThetechnical marketing agency Butter and Salt worked together with a machine manufacturer to think about how service could be made more efficient and customer-friendly. The result is a system called Pink Flamingo, the basic version of which is a document management system in which, for example, machine master data, maintenance manuals, operating instructions or maintenance logs are stored digitally for each machine. All machines sold by a machine supplier can be supplied with an individual QR code. This leads to a web-based database in which all documents for each machine are stored and maintained by the manufacturer or supplier. Authorized machine operators can access these documents by scanning the code, explains Managing Director Florian Schildein in an interview with PLUS.

All information about the machines is made available to the customer digitally. The documents are maintained in the background by the machine manufacturer and updated in the event of adjustments. The system can be expanded, including with training modules, online stores and access to ERP and CRM data via an API interface. No interface to the machine is required, as the system does not access machine data. It works independently in its own environment and only via the machine manufacturer's Internet platform developed for this purpose. All data and customer information is therefore held by the machine partner. Two-factor authentication is used to verify a user's identity. The platform also has SSL encryption for secure data transmission.

With Pink Flamingo, the machine manufacturer can offer its customers fast, direct service, provide training materials or exploit cross-selling potential, which results in increased efficiency in first-level support. The end customer of the machine has access to the latest version of all required documents around the clock, every day, as the data is maintained by the machine supplier. The end customer has access to spare parts and direct online ordering options. They are also reminded of maintenance and service appointments-dir/vk-

www.pinkflamingo.support

www.butter-and-salt.de

Hall 4 Stand 124

X-ray inspection and fast X-ray counting of electronic components

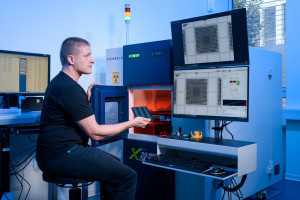

X-ray inspection provides high-contrast images of the components to be inspected before delivery to the customer (Image: 4Source electronics)4 Source electronics procures original electronic components on the market, but also buys up residual quantities and stock. Quality assurance checks the quality and quantity of the purchased stocks before they are delivered. For all components whose innermost parts are not visible, X-ray inspection is used to x-ray the component and ensure quality through comparative analysis.

X-ray inspection provides high-contrast images of the components to be inspected before delivery to the customer (Image: 4Source electronics)4 Source electronics procures original electronic components on the market, but also buys up residual quantities and stock. Quality assurance checks the quality and quantity of the purchased stocks before they are delivered. For all components whose innermost parts are not visible, X-ray inspection is used to x-ray the component and ensure quality through comparative analysis.

Due to the high demand for chips, the component procurer has now invested in a further X-ray inspection system for quality control, namely the AXI system IM9000 from the manufacturer TechValley with a 110 kV closed X-ray tube. The new system is characterized by high image data quality, various analysis options, high contrast depth and short throughput times.

An X-ray component counter, also from TechValley, has significantly increased the inspection speed of the incoming goods quantity. Whereas an employee needed around five minutes per roll with the mechanical counting devices, the counting and documentation process is now completed in ten seconds. The X-ray component counter automatically saves the results, including the X-ray image, in the database. The component rolls no longer need to be removed from the packaging before counting. This saves time and is gentle on the material.

Before the purchase, the 4Source electronics quality team tested the component counter satisfactorily in the demo center of SmartRep, TechValley's distributor in Germany, to find out how the counter works with partial quantities, full rolls, very small components, very large components and special shapes.-dir/vk-

Halla A4 Stand 230

Paggen: Reliably soldering large sample boards

Image: PaggenManySMEs and start-ups often face unsolvable challenges when creating prototypes if they have to solder large boards. Switching to contract manufacturers usually fails due to long delivery times and the purchase of a 'used' machine often fails due to the space required.

Image: PaggenManySMEs and start-ups often face unsolvable challenges when creating prototypes if they have to solder large boards. Switching to contract manufacturers usually fails due to long delivery times and the purchase of a 'used' machine often fails due to the space required.

Paggen is now launching the HR30 based on the existing HR10 benchtop unit. The compact tabletop reflow oven offers all the functions required of a modern soldering device. Boards up to a size of 410 x 600 mm and components with a height of 55 mm at the top and 30 mm at the bottom can be soldered in the process chamber. An integrated fume extractor with 1500 l/h and 2 m exhaust air hose shortens the process times and is also part of the equipment, as is a connection for N2 with the associated control for soldering in an inert atmosphere. A connected load of 7800 W offers sufficient power reserves to realize even steep gradients. The soldering process itself is carried out using a combination of IR radiation and convection heat, which is gentle on components. Heat shields minimize the light-dark problem of IR radiation and ensure perfect heat transfer. The motorized door opening is programmable and starts the adjustable rotors of the powerful forced cooling system after the reflow process.

Programming via touch display and an automated process sequence ensure reliable operation of the system - regardless of whether linear or saddle profiles are to be created, the rise gradients changed, soldered with or without N2, or drying programs created. All parameters can be changed and controlled on the touch display. A total of seven measuring thermocouples (three permanently installed in the chamber and four freely positionable) enable seamless monitoring of the entire soldering process. The soldering profile and documentation of the process can be followed in real time via the USB interface. The MTPWIN software required for this is included in the scope of delivery and is supplied on a USB stick.

-dir/mh-

Small series soldering in the vapor phase

Vapor phase soldering has established itself wherever large masses or particularly critical components such as LEDs need to be soldered reliably and gently. It is considered the most effective process for soldering SMD assemblies, as it prevents the assembly from overheating in an inert environment. The process also reduces energy costs thanks to the high energy density during heat transfer.

At SMTConnect, PAGGEN will be showcasing the VP-Two for PCBs up to 300 x 350 mm and is fulfilling the wish of many customers for an inexpensive tabletop device with a high level of operating convenience. For developers, schools, start-ups and manufacturers of small series, the advantages of condensation soldering are obvious. Lengthy profile determination and overheating of components are a thing of the past. Even highly dynamic soldering profiles can be reliably controlled thanks to powerful fans and a height-adjustable PCB carrier, giving users a high degree of flexibility.

The Vapor Phase Two is operated conveniently and precisely via touchscreen. The cover to the process chamber lifts automatically and makes it easier to place a PCB. Once the assembled PCB has been placed on the lift and the soldering process has started, the process runs fully automatically. The temperature profile used, as well as the actual temperature reached, can be tracked in real time in a shared diagram on the display. The temperature is regulated to within 2-3 °C in order to follow the specified profile. In addition to displaying the real-time temperature data on the screen, the Vapor Phase Two offers a viewing window with interior lighting, through which the process chamber is perfectly visible.

The economical device weighs just 35 kg, consumes only 2 kWh of power and requires just 0.8 ml of Galden per soldering process. The integrated water cooling is kept stable by 6 fans, so that no separate water connection is required. The Vapor Phase Two can import individual soldering profiles via an SD card. These profiles are used to adapt the heating power and lift position to different solder pastes and PCB technologies. An attractive price-performance ratio and the high process reliability speak in favor of its use in prototyping, where the first attempt must be a success.

Hall 4 Stand 144

Pannacol: 'Black&Light' at the SMTConnect

We already presented Pannacol's black adhesives for UV curing in issue 2/2023 of PLUS. With the 'Black&Light' series, Panacol has developed epoxy resin adhesives from the Vitalit product range that can also be cured in thicker layers using UV radiation without resorting to secondary curing mechanisms. The black adhesives are suitable for various encapsulations, glob tops or edge bonders in electronics production as well as for optical adhesive systems where high OD values ('optical density') are required in optoelectronic applications, for example to minimize reflections or to achieve certain transmission values for sensors.

The 'Black&Light' technology is compatible with other Vitralit epoxy resin adhesives and can be combined depending on the requirement for blackness and the required depth of cure. While conventional black epoxy resin adhesives usually have to be stored deep-frozen, 'Black&Light' adhesives can be stored and shipped at room temperature or refrigerated to the maximum.-dir/mh-

www.pannacol.de

www.hoenle.de

Hall 4 Stand 131

SPEA: Flying probe system for high-volume series production

SPEA will be presenting test equipment for electronics production at SMTconnect in Nuremberg. On display will be the SPEA 4080 flying probe tester and the SPEA 3030 board tester series. The SPEA 4080 flying probe tester is still the only flying probe system with linear motors and optical encoders on all movement axes. It is used in high-volume series production and also for small and medium quantities. The SPEA 4080 is a multifunctional test system with a total of 8 configurable multi-tool test heads for double-sided contacting. From a pool of 50 test tools, a total of 28 tools can be mounted on the test heads to cover a wide range of test requirements. The combination of electrical tests, optical inspection, thermal tests, 3D scans, light tests, etc. offers almost complete test coverage. The Flying Probe Tester offers an extended test area for assemblies up to 1200 x 668 mm in size and weighing up to 20 kg. The boards can be equipped with high components up to 150 mm on both sides. A unique selling point is the tester's own 'Leonardo' system software, which combines all functions from data transfer to automatic test program generation and debugging in a single interface. Third-party solutions are not necessary, as SPEA systems come with their own complete and independent software.

In-circuit test platforms for testing various assemblies

SPEA board testers with needle bed adapters are scalable in-circuit test platforms for testing analog, digital and power electronics assemblies. The multi-core technology enables several boards to be tested simultaneously in one system. This reduces cycle times and increases throughput. Thanks to the dedicated CPU on each core, there are no delays between the instrumentation and the PC. High-performance relays ensure fast switching times. The system offers the possibility of carrying out different measurements simultaneously.

The '3030 Inline' will be shown at the trade fair as a representative of the system family. The tester is SMEMA and HERMES compliant and designed for use in SMT or fully automated production lines. Equipped with loading and unloading systems, it can also be used as a test cell.

Hall 4A Booth 124

Zestron: Reliability of power and signal electronics in the high-voltage and e-mobility sector

Board tester '3030 Inline' (Image: Spea)In order to meet the growing importance of this area and the associated economic and technical challenges facing manufacturers, Zestron is exhibiting at PCIM this year and is also represented on the stand of the 'European Center for Power Electronics e. V.' (ECPE). The company provides comprehensive support to electronics manufacturers by installing a cleaning process or determining the failure risk of assemblies in order to recommend specific remedial measures. At PCIM, the expert team of engineers and technologists will provide advice on the topics of technical and ionic cleanliness, insulation coordination, moisture resistance and flux removal.

Board tester '3030 Inline' (Image: Spea)In order to meet the growing importance of this area and the associated economic and technical challenges facing manufacturers, Zestron is exhibiting at PCIM this year and is also represented on the stand of the 'European Center for Power Electronics e. V.' (ECPE). The company provides comprehensive support to electronics manufacturers by installing a cleaning process or determining the failure risk of assemblies in order to recommend specific remedial measures. At PCIM, the expert team of engineers and technologists will provide advice on the topics of technical and ionic cleanliness, insulation coordination, moisture resistance and flux removal.