On the way to make a plasma phenomenon ready for the industry.

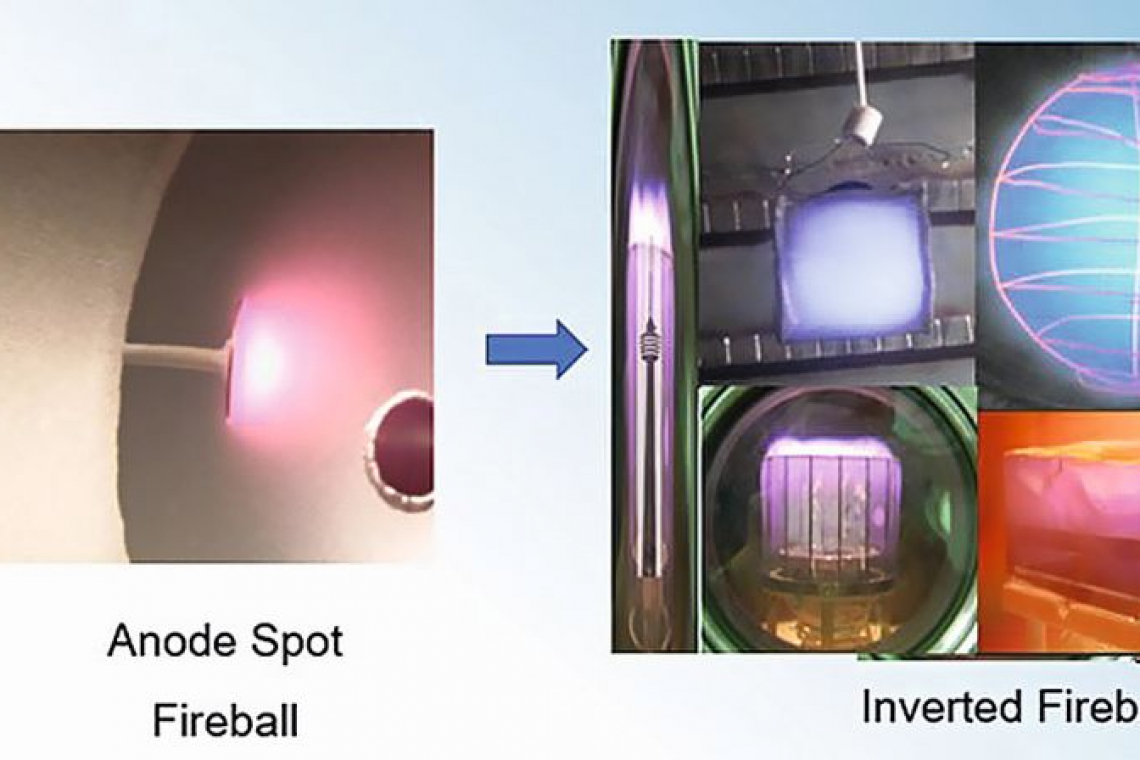

The IFB, a plasma phenomenon, was discovered in the early 2010’s at the University of Innsbruck by Prof Stenzel, Dr. Gruenwald et al.[ 1,2]. At the beginning it was just seen as an evolution of a plasma sheath but after the initial experiments it soon became clear that IFBs have certain properties that make them ideal for surface treatments [3,4]. Firstly, they form very dense plasma in a well-defined volume (i.e. inside a gridded anode). Secondly, the plasma potential inside an IFB is very homogeneous, which also makes the plasma homogeneous and thirdly, IFBs are very efficient in sustaining their plasma. This leads to the possibility of large area coatings, or treatments at comparably high speed and superior uniformity with savings in process time and energy. Yet another advantage of IFBs is their versatility as they can be used for surface cleaning, etching, deposition and activation. As Figure 1 shows, an IFB confines the plasma within different shapes. Thus, the dense plasma is only applied directly onto the substrate, is only present on the work-piece and reduces unwanted coating or contamination of the chamber walls.

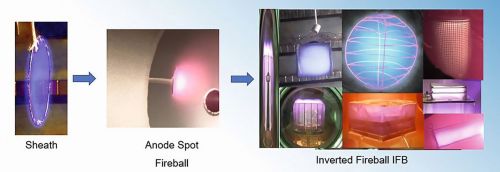

The theory sounds great, and the practice? The first results were promising and they keep improving. In recent years, the authors of this article built an international network of scientists, engineers and industry partners to propel this new technology forward. The first results with relevance for several industries are very encouraging: With IFB-PECVD Carbon-Nano-Walls, Nano-Diamonds, DLC and large area Graphene (Fig. 2) were successfully produced. Furthermore, amorphous Carbon-Films with unmatched surface smoothness and high uniformity values have been already demonstrated (Fig. 3).

![Fig. 3: AFM image of an IFB deposited carbon film with a surface roughness below 0.25 nm [5] Fig. 3: AFM image of an IFB deposited carbon film with a surface roughness below 0.25 nm [5]](/images/stories/Abo-2025-01/thumbnails/thumb_gt-2025-01-071.jpg) Fig. 3: AFM image of an IFB deposited carbon film with a surface roughness below 0.25 nm [5]

Fig. 3: AFM image of an IFB deposited carbon film with a surface roughness below 0.25 nm [5]

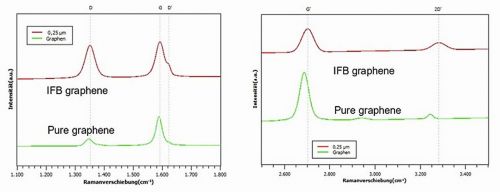

Not only does this technology play a role for depositing different materials and for material processing technologies. The biggest advantage is the concentration of the plasma on the workpiece with a measured up to 15-fold increase in plasma density (Fig. 4). This opens new fields and launches a new approach for advanced materials processing, e. g. for the deposition of large area graphene or diamond NV-centers. Obviously, there is an overall improvement for the efficiency of plasma processing technologies. Not to mention the more effective use of resources and a reduced machine maintenance resulting in a reduction of machine downtime. Here, experts estimate a potential for a fourfold higher machine usage time between maintenance intervals.

Fig. 4: 10-fold increase of plasma density with additional 20 W input power (left)6 and plasma density in- and outside a typical IFB (right)

Fig. 4: 10-fold increase of plasma density with additional 20 W input power (left)6 and plasma density in- and outside a typical IFB (right)

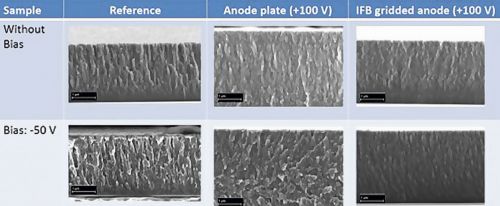

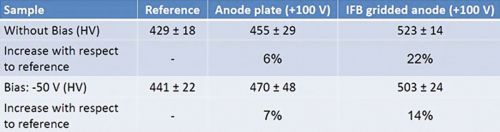

A thesis about the very first IFB implemented in a conventional magnetron sputter device has been published in 2024, and another one, with a deeper look into the plasma physics of IFBs, is on its way. More theses and R&D projects are planned or already on their way into the kick-off phase. Very promising lab results for PVD magnetron sputtering (Fig. 5) with a significant in film properties have been achieved.

Fig. 5: SEM micrographs of fracture cross sections of Titanium films (total pressure 0.3 Pa) deposited by IFB magnetron sputteringity - dense microstructure with IFB

Fig. 5: SEM micrographs of fracture cross sections of Titanium films (total pressure 0.3 Pa) deposited by IFB magnetron sputteringity - dense microstructure with IFB

Fig. 5: overall increase in film quality

Fig. 5: overall increase in film quality

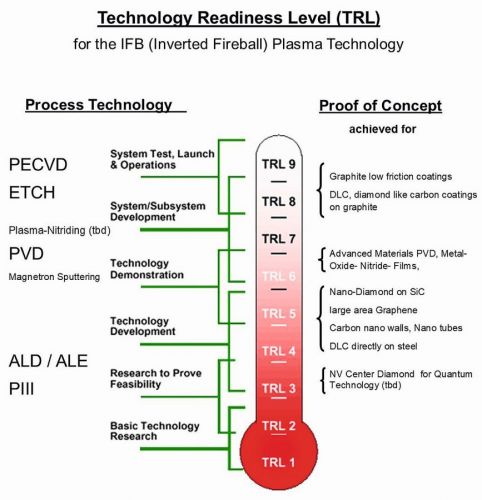

To demonstrate what is possible with IFBs, several tests with advanced and not easy to process materials have been conducted and evaluated. Figure 6 shows the technology readiness level (TRL) for already achieved proofs of concept done via PHD-, master- and bachelor-theses and laboratory tests at institutes and universities as well as on industrial equipment.

Fig. 6: Technology Readiness Level (TRL) for process technology and already achieved proofs of concept for advanced materials

Fig. 6: Technology Readiness Level (TRL) for process technology and already achieved proofs of concept for advanced materials

Contact authors via:

Literatur

[1] Stenzel, R. L., et al. „Transit time instabilities in an inverted fireball. I. Basic properties.“ Physics of Plasmas 18.1 (2011).

[2] Stenzel, R. L., et al. „Transit time instabilities in an inverted fireball. II. Mode jumping and nonlinearities.“ Physics of Plasmas 18.1 (2011).

[3] Gruenwald, J., et al. „Further experiments on inverted fireballs.“ Proc. 38th EPS Conf. Plasma Phys. 2011.

[4] Mayer, M., et al. „Diamond like carbon deposition by inverted fireballs.“ Materials Today: Proceedings 3 (2016): S184-S189.

[5] Gruenwald, J., et al. „Inverted fireball deposition of carbon films with extremely low surface roughness.“ Carbon Letters 33.1 (2023): 225-231.

[6] Eichenhofer, Gerhard, et al. „Measurement of inverted n-hexane fireball properties with a Multipole Resonance Probe.“ The Journal of Technological and Space Plasmas 3.1 (2022): 109-117.