Monthly report from Dr. Anand Kumar Sharma, Bengaluru/India

Nickel-Based Nanocomposites with Lubricating Nanoparticles

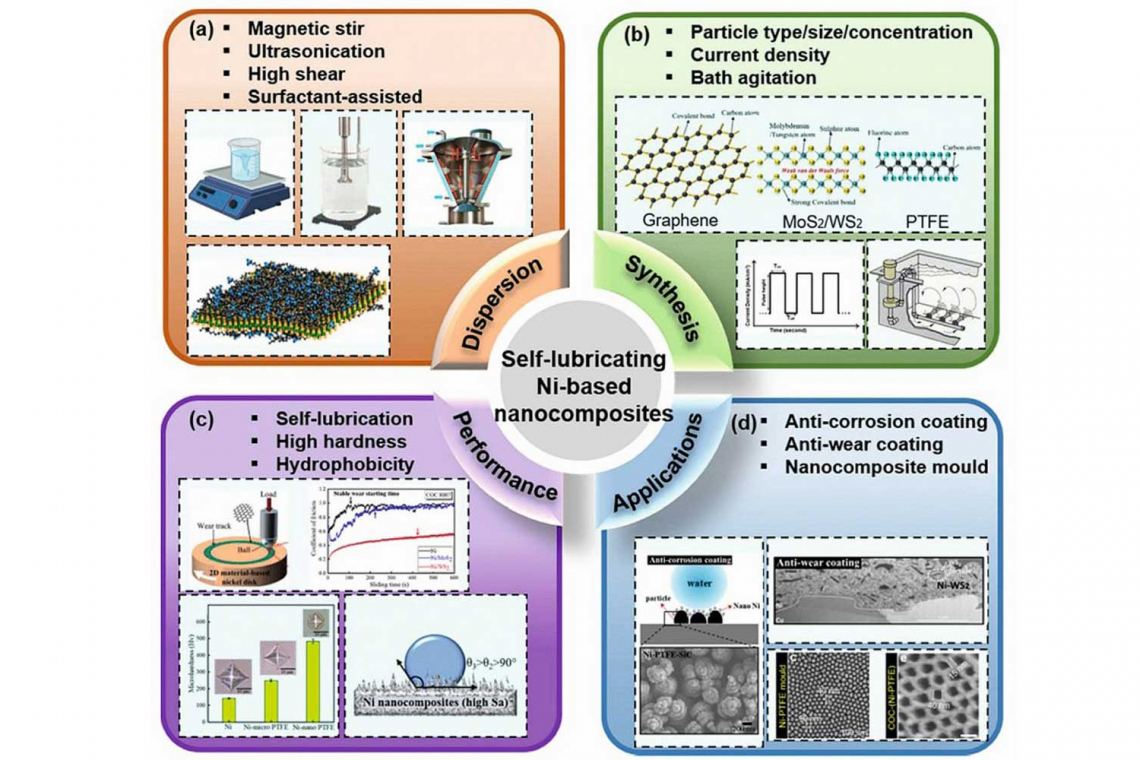

Electrodeposition is an efficient, cost-effective method for fabricating Ni-based nanocomposites. It allows precise control over coating composition, offering an environmentally friendly alternative to traditional hard chromium coatings. Advancements such as surfactant-assisted, ultrasonic, and high-shear techniques improve nanoparticle dispersion within the nickel matrix, ensuring uniform coatings. Figure 1/Cover image illustrates common dispersion methods, process parameters, performance, and applications of lubricating nanocomposites [1].

Lubricating Nanoparticles and Their Function

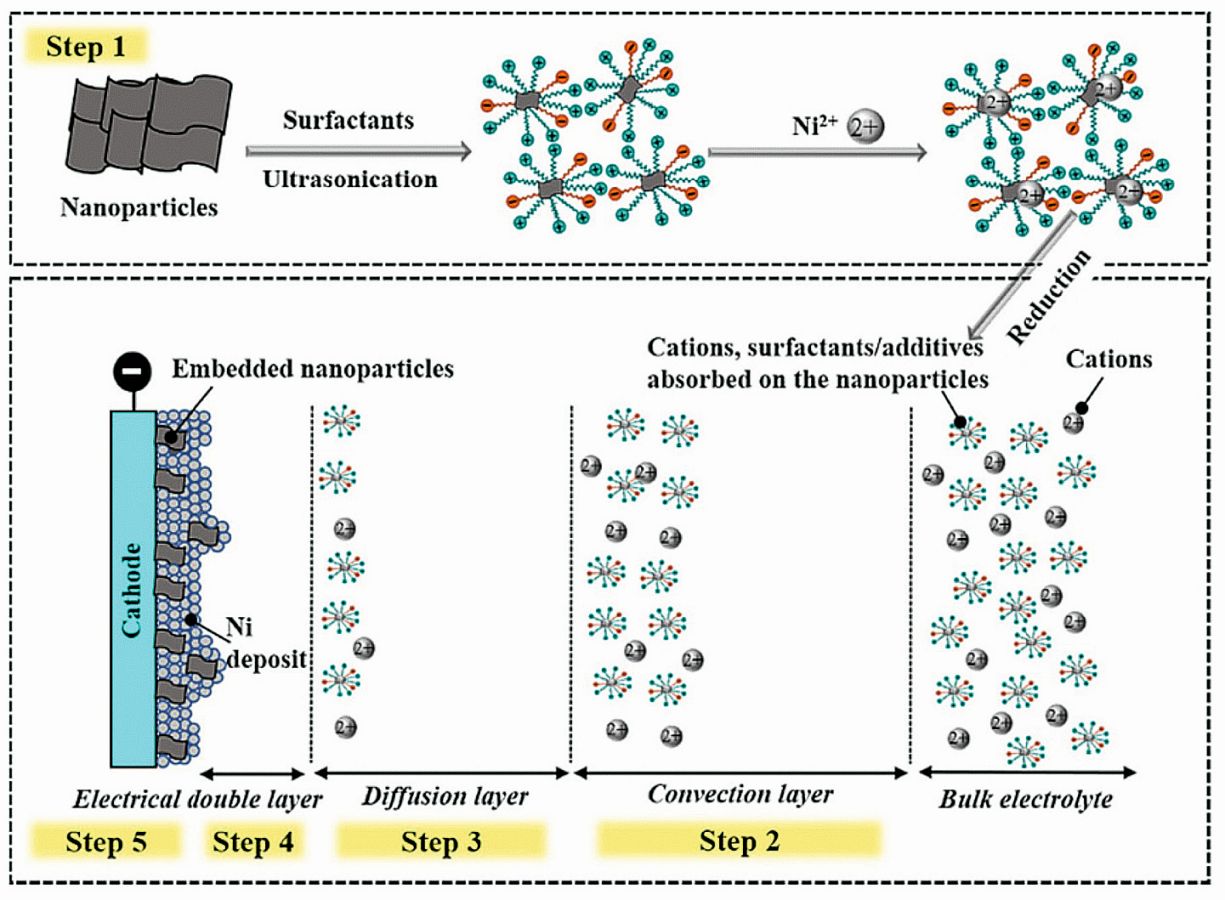

Lubricating nanoparticles form protective films or tribo-layers at moving interfaces, preventing direct metal-to-metal contact. This reduces wear and frictional heating, extending the lifespan of mechanical components. Certain nanoparticles, such as fluoropolymers and carbon-based materials, enhance corrosion resistance and thermal stability, improving coating durability under extreme conditions. Figure 2 presents the process steps of nanoparticle co-deposition onto the metal matrix [1].

Ni-based nanocomposites exhibit superior hardness, wettability, and wear resistance while reducing friction. Incorporating nanoparticles such as carbides, metal oxides, 2D materials, and fluoropolymers (PTFE) imparts self-lubricating characteristics, extending component lifespans. These composites find applications in aerospace, automotive, biomedical, and high-speed machinery industries.

Fig. 2: Process steps of nanoparticle co-deposition onto the metal matrix: 1. ionic cloud formation around particles; 2. particle convection toward the cathode; 3. particle diffusion through the hydrodynamic boundary layer; 4. particle diffusion through the concentration boundary layer; 5. particle adsorption onto the cathode surface

Fig. 2: Process steps of nanoparticle co-deposition onto the metal matrix: 1. ionic cloud formation around particles; 2. particle convection toward the cathode; 3. particle diffusion through the hydrodynamic boundary layer; 4. particle diffusion through the concentration boundary layer; 5. particle adsorption onto the cathode surface

Deposition Techniques and Process Optimization

The deposition parameters, such as electrolyte composition, pH, current density, and temperature, significantly influence the structural and tribological characteristics of the coatings. Pulse electrodeposition and electroless deposition ensure uniform nanoparticle distribution, enabling coatings with controlled porosity for advanced engineering applications.

2D Solid Lubricants

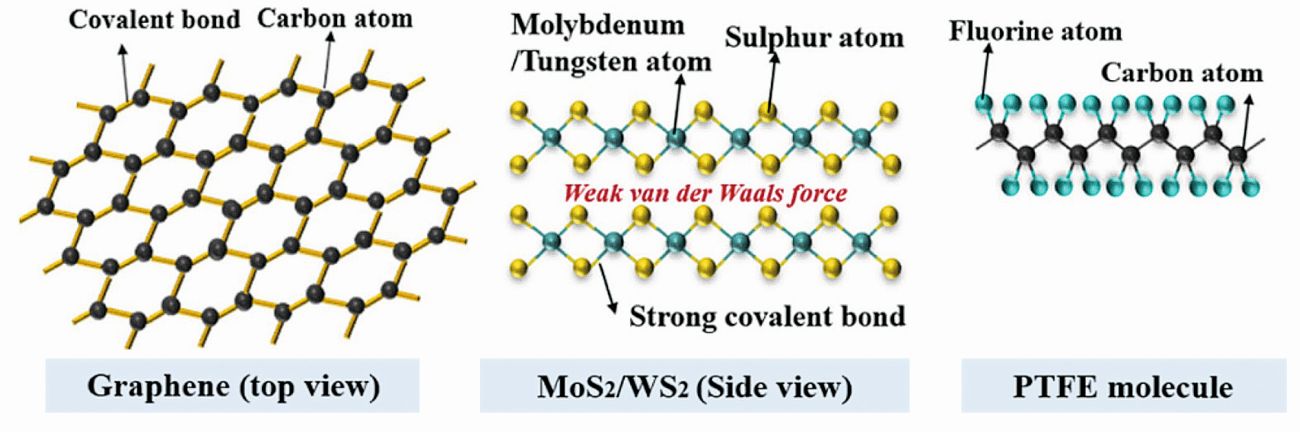

Graphene, MoS₂, and h-BN improve the tribological properties of Ni-based coatings [2]. Graphene, with its strong in-plane carbon-carbon bonding and weak interlayer van der Waals forces, reduces friction between contact surfaces. When incorporated into nickel matrices, it enhances hardness and wear resistance while forming a protective film that mitigates oxidation wear and furrowing, particularly at high temperatures.

Other solid lubricants, such as molybdenum disulphide (MoS2) and hexagonal boron nitride (h-BN), facilitate smooth sliding motion due to their layered structures. Figure 3 presents the structures of graphene, MoS2/WS2, and PTFE, highlighting their role in lubrication [3].

Fig. 3: Structures of graphene, MoS2/WS2, and PTFE

Fig. 3: Structures of graphene, MoS2/WS2, and PTFE

Nano-Ceramic Additives for Strength and Stability

Nano-ceramic additives like aluminum oxide (Al2O3), silicon carbide (SiC), and zirconium dioxide (ZrO2) increase surface hardness, enhancing load-bearing capacity of the coatings. Their dispersion within the nickel matrix prevents localized wear and ensures uniform stress distribution, reducing premature failure. These nano-ceramics also exhibit excellent thermal stability, making them ideal for high-temperature applications where conventional coatings may degrade.

Eco-Friendly and Advanced Coating Solutions

Ni-W alloy coatings developed via pulsed electrodeposition exhibit excellent tribological performance, dissipating friction-generated heat efficiently. Their multilayered architecture extends the service life of critical components such as gears, bearings, and other moving parts. Such coatings contribute to sustainable engineering by reducing energy losses due to friction [4].

Synergistic Effects of Hybrid Coatings

Combining solid lubricants like graphene with MoS2 or h-BN enhances thermal and mechanical stability while ensuring long-lasting lubrication. Ni-W-P coatings with nano-ceramic additives exhibit superior wear resistance and self-repairing capabilities, making them valuable in environments where mechanical components undergo continuous wear and require minimal maintenance such as aerospace and automotive applications [5].

Future Prospects and Challenges

Despite the advantages of Ni-based nanocomposites, challenges remain in achieving uniform nanoparticle dispersion, controlling agglomeration, and optimizing deposition parameters for large-scale production. Advanced surfactant-assisted dispersion techniques and innovative electrodeposition approaches, such as magnetic field-assisted and laser-assisted methods, are needed. Future research will explore self-healing coatings with stimuli-responsive nanoparticles for autonomous repair. Further, developing non-toxic, environmentally friendly Ni-based coatings will support greener manufacturing processes.

Conclusion

Ni-based nanocomposites with lubricating nanoparticles present a promising strategy for high-performance, wear-resistant coatings. Continued advancements in electrodeposition techniques and sustainable manufacturing will drive their widespread adoption, enhancing efficiency and longevity across various industries.

Electrochemical Treatment of Metal-Finishing Wastewater

Nitrate pollution from industrial effluents and fertilizers poses environmental and health risks. Metal-finishing wastewater (MFW) contains high levels of nitrate and heavy metals, posing environmental and health risks. This study evaluates a Ti/Co3O4 cathode in an electrochemical reduction (ECR) process for simultaneous nitrate and heavy metal removal, with ammonia recovery as struvite to support a circular economy. A divided electrochemical cell with a Ti/Co3O4 cathode was used. Key parameters include:

- Initial nitrate-N concentration: 500-1000 mg/L

- Current density: 10-30 mA/cm2

- Treatment time: 3 hours

- Cathode reusability: 10 cycles

Nitrate reduction reactions:

- NO3– + e– + H2O → NO₂• + 2 OH–

- NO2• + e– → NO2–

- 3 NO2– + 12 H+ + 9 e– → 1.5 N2 + 6 H2O

- NO2– + 7 H+ + 6 e– → NH3 + 2 H2O

The electrochemical process achieved 95 % removal of 750 mg/L nitrate-N within 3 hours at a current density of 20 mA/cm2, with approximately 80 % selectivity for environmentally benign N2. Even at 1000 mg/L nitrate-N, the system maintained over 90 % removal efficiency with around 65 % current efficiency. Complete heavy metal removal occurred via alkaline pH precipitation. Ammonia-N generated during nitrate reduction was successfully recovered as struvite, reducing ammonia levels below 50 mg/L. The Ti/Co3O4 cathode demonstrated stable performance over 10 reuse cycles with minimal Co(II) leaching. The divided cell enhances nitrate removal by maintaining an alkaline pH, which promotes N2 formation, while optimized current density further increases N2 selectivity. This method supports a circular economy by recovering ammonia as struvite and removing heavy metals, with minimal cobalt leaching and robust cathode reusability improving long-term sustainability. Overall, the process offers a sustainable and efficient solution for MFW treatment, reducing environmental impact while promoting resource recovery.

J. Ingle; U.D. Patel: Electrochemical treatment of metal-finishing wastewater using Ti/Co3O4 electrode: Efficient removal of nitrate and heavy metals, and recovery of struvite, J. Environ. Manage., 377 (2025) 124659. doi: 10.1016/j.jenvman.2025.124659

AI-Powered Imaging for Advanced Corrosion Assessment

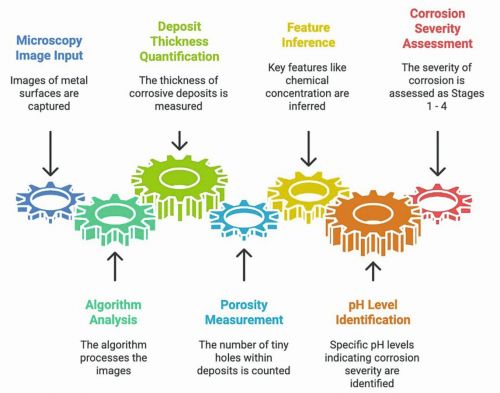

Fig. 4: AI-driven corrosion assessment method showing critical input features and evaluation metricsResearchers at the Indian Institute of Science (IISc), Bengaluru, have developed an automated, AI-driven method to assess corrosion severity in industrial equipment using optical microscopy (OM) images. This novel approach leverages unsupervised machine learning, specifically k-means clustering, to analyse corroded metal surfaces without requiring predefined labels or human input—an advantage in corrosion studies where annotated datasets are often limited.

Fig. 4: AI-driven corrosion assessment method showing critical input features and evaluation metricsResearchers at the Indian Institute of Science (IISc), Bengaluru, have developed an automated, AI-driven method to assess corrosion severity in industrial equipment using optical microscopy (OM) images. This novel approach leverages unsupervised machine learning, specifically k-means clustering, to analyse corroded metal surfaces without requiring predefined labels or human input—an advantage in corrosion studies where annotated datasets are often limited.

The method focuses on two key indicators of under-deposit corrosion (UDC) – deposit thickness and local porosity within 5 μm × 5 μm regions. These parameters are extracted from microscopy images and used to infer the chloride concentration factor and local pH, which are critical to identifying corrosion severity. A clear correlation was observed: as deposit thickness increases, chloride levels rise and the environment becomes more acidic. Notably, corrosion was found to escalate sharply when pH dropped below 2.8 – 3.0, marking the transition to the most severe stage (Stage 4).

As illustrated in Figure 4, the high-level architecture of the AI-based method highlights how these microstructural and chemical features are used to classify corrosion stages without human intervention.

Tested on 48 ex-service OM images of steam generator tubes—where UDC is common and difficult to evaluate—the method achieved a classification accuracy of approximately 73 %, outperforming conventional manual assessment methods in both speed and consistency. This work demonstrates that surface morphology and local chemical conditions are more tightly coupled than previously understood, offering new predictive markers for corrosion progression. The fully automated framework presents a scalable solution for data-driven corrosion monitoring, with promising applications in predictive maintenance of high-temperature industrial systems.

RajKumar, A. et al.: Unsupervised machine learning for automated corrosion staging using optical microscopy images, npj Mater. Degrad., 9 (2025) 83. doi: 10.1038/s41529-025-00635-1

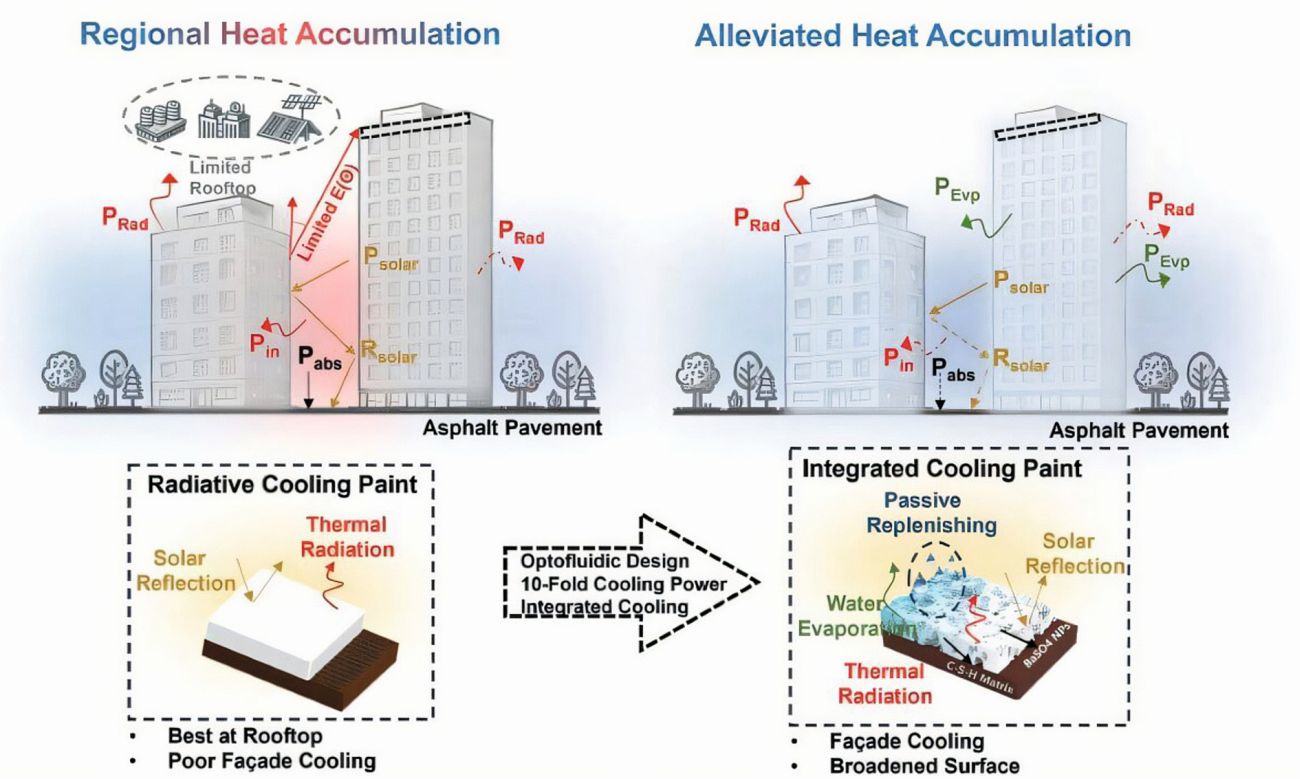

Passive Cooling Paint Achieves 10 x Cooling via Self-Replenishing Mechanism

A newly developed passive cooling paint, CCP-30, designed by Fei et al., combines radiative, evaporative, and reflective mechanisms to deliver up to 10 times the cooling power of standard commercial paints, achieving an estimated 30-40 % energy savings. Featuring a nanoparticle-modified calcium silicate hydrate (C-S-H) structure, the paint offers 88-92 % solar reflectance, 95 % infrared emittance, and retains approximately 30 % water by weight. Its self-replenishing water capacity enables consistent evaporative cooling – even on vertical surfaces and in humid climates – making it effective in reducing building energy use and mitigating urban heat island effects, as illustrated in Figure 5. Field tests in Singapore confirmed its superior performance and long-term sustainability benefits.

Fei, J., et al.: Passive cooling paint enabled by rational design of thermal-optical and mass transfer properties, Science, 388, no. 6751 (2025) 1044-1049. doi: 10.1126/science.adt3372

Fig. 5: Performance comparison between CCP-30 and conventional cooling paints for building applications

Fig. 5: Performance comparison between CCP-30 and conventional cooling paints for building applications

Upcoming Electrochemistry Conferences

- ACMS-2026. Second International Conference on Advances in Chemical and Materials Sciences. April 12 to 14, 2026. Kolkata; https://ceie.org.in

Literatur

[1] Guan, T.; Zhang, N.: Recent advances in electrodeposition of nickel-based nanocomposites (...), Nanomanuf. Metrol., 7, no. 1 (2024) 25. doi: 10.1007/s41871-024-00245-6

[2] Tan, S. et al.: Optimization of pretreatment schemes for electroless nickel plating of three solid lubricants. Wear, 570 (2025) 205939. 10.1016/j.wear.2025.205939

[3] Parucker, M.L et al.: Development of self-lubricating composite materials of nickel with molybdenum disulfide, graphite (...): preliminary study, Mat. Res., 17(Suppl. 1) (2014) 180-185. doi: 10.1590/S1516-14392013005000185

[4] Bathini, L. et al.: Compositionally modulated Ni-W multilayer coatings: (...), Tribol. Int., 179 (2023) 108145. doi: 10.1016/j.triboint.2022.108145

[5] M. Chen et al.: Synergistic effect between nano-ceramic lubricating additives and electroless deposited Ni-W-P coating, Chin. J. Mech. Eng., 26, no. 1 (2013) 114-120. doi: 10.3901/CJME.2013.01.114